Recovery system and recovery method of nickel-cobalt hydroxide

A nickel-cobalt hydroxide and recovery system technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of excessive consumption of auxiliary materials, high energy consumption, etc., to reduce recycling costs and shorten the recycling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments. The embodiments shown below do not have any restrictive effect on the content of the invention recorded in the claims. Further, the entire content of the composition expressed in the following embodiments is not limited to the solution necessary as a solution to the invention recorded in the claims.

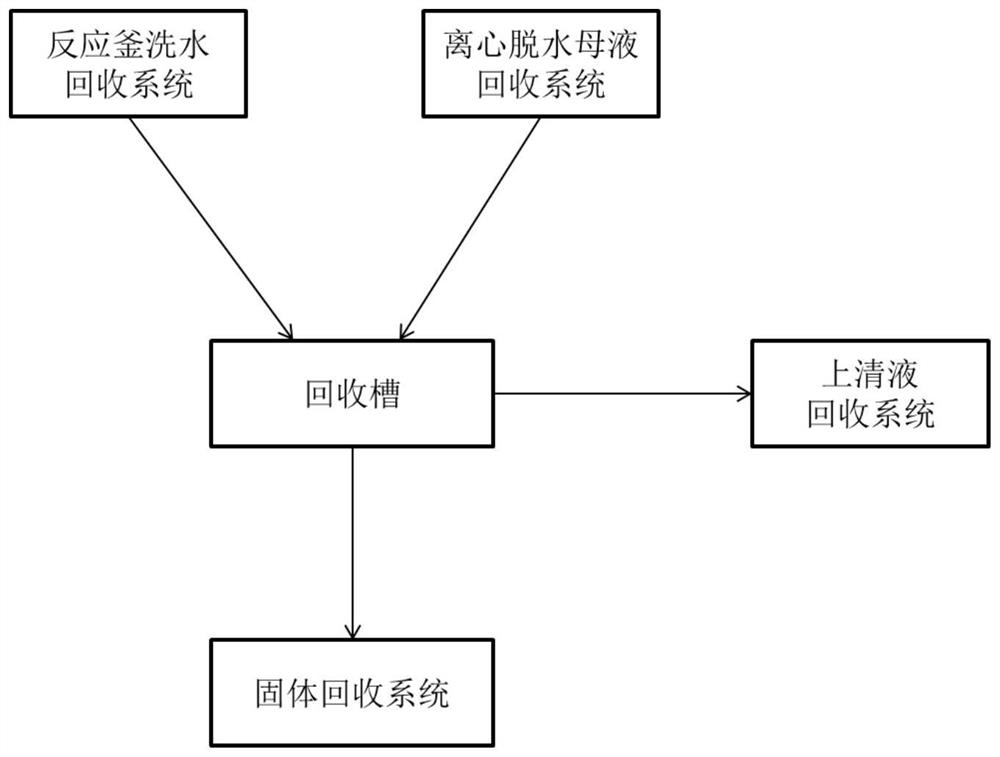

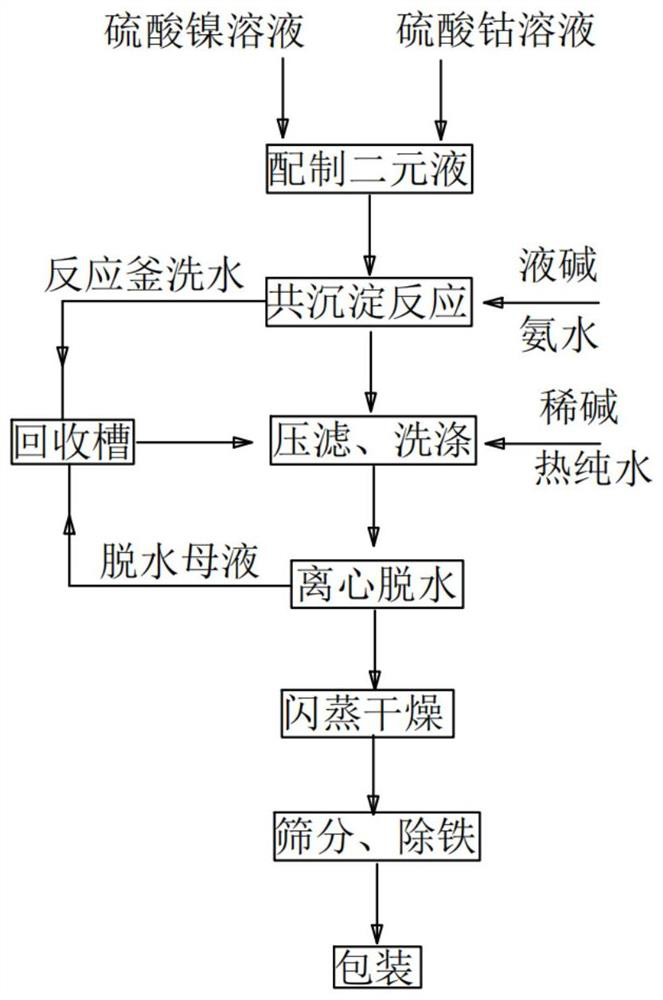

[0020] Reference attached Figure 1 , a kind of nickel-cobalt hydroxide recovery system, including a reactor washing water recovery system, centrifugal dehydration mother liquor recovery system, recovery tank, supernatant recovery system, and solid recovery system, the recovery tank is provided with an inlet, a supernatant outlet and an outlet, the inlet of the recovery tank is connected with the reactor washing water recovery system, centrifugal dehydration mother liquor recovery system, the supernatant outlet is connected with the supernatant recovery sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com