Array microelectrode, preparation method thereof and ultrasonic device

A micro-electrode and array technology, applied in the field of micro-electrodes, can solve the problems of high requirements for operation and slurry fluid, high requirements for slurry fluid, poor customization, etc., to reduce process conditions and operation requirements, low cost and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

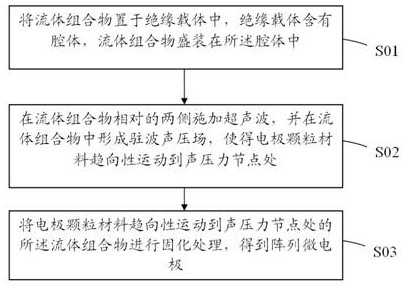

[0026] Embodiments of the present application provide a method for preparing an array microelectrode. combine Figure 1 and Figure 2 , the preparation method of the present application embodiment array microelectrode comprising the following steps:

[0027] S01: The fluid composition is placed in the insulating carrier 01, the insulating carrier 01 contains a cavity 11, the fluid composition is encased in the cavity 11;

[0028] S02: Ultrasonic waves are applied on opposite sides of the fluid composition, and a standing wave acoustic pressure field is formed in the fluid composition, so that the electrode particle material contained in the fluid composition tendentiously moves to the sound pressure node;

[0029] S03: The fluid composition of the electrode particle material tendentiously moved to the acoustic pressure node is cured to obtain an array of microelectrodes.

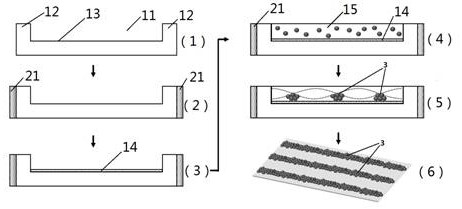

[0030] Wherein, the insulating carrier 01 may be Figure 2 (1) in Figure sum Figure 3 The following text shown r...

Embodiment 1

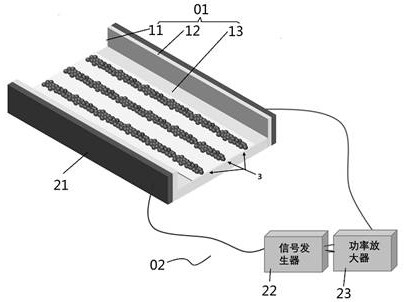

[0054] The present embodiment provides a method for preparing an array microelectrode and a corresponding ultrasonic device. Wherein, the ultrasound device such as Figure 2 and Figure 3 The above application shown in the application ultrasonic apparatus of the embodiment.

[0055] The preparation method of array microelectrodes comprises the following steps:

[0056] S1: The use of 3D printing technology to construct a polymethyl methacrylate insulating carrier 01, the insulating carrier 01 is provided with a cavity 11 for carrying the fluid composition, the cavity 11 structure such as Figure 2 (1) as shown in FIG.; and lay an insulating substrate 14 on the bottom 13 surface of the cavity 11;

[0057] S2: The piezoelectric transducer 21 is pasted on both sides of the wall 12 of the cavity 11 by conductive glue as an ultrasonic emitter end, such as Figure 2 (2) shown in the figure, piezoelectric transducer 21 are in series signal generator 22 (waveform generator) and power amplifie...

Embodiment 2

[0065] The present embodiment provides a method for preparing an array microelectrode and a corresponding ultrasonic device. Wherein, the ultrasound device such as Figure 2 and Figure 3 The above application shown in the application ultrasonic apparatus of the embodiment.

[0066] Array microelectrode preparation method as in the above example 1 preparation method. The differences are:

[0067] The fluid composition in step S3 is to dilute the polydimethylsiloxane, the temperature curing agent and the gold nanoparticles mixed with ultrapure water, and the mixture is uniformly removed to prepare the bubbles to obtain, the mass ratio of the polydimethylsiloxane, the temperature curing agent and the gold nanoparticles is 100: 10: 2;

[0068] Step S4 Input Ultrasonic Frequency Control is 230 kHz and Voltage is 30 V;

[0069] It has been measured that the array spacing of the microelectrode wire containing the flexible array microelectrode 3 prepared by the present embodiment is 3500μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com