PVC (polyvinyl chloride) and preparation method thereof

A technology of polyvinyl chloride and vinyl chloride, which is applied in the field of PVC polyvinyl chloride and its preparation, can solve the problems of deep pot body, liquid retention, and inconvenient cleaning of the bottom of the pot body for workers, and achieve toughness enhancement, convenient cleaning, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A PVC polyvinyl chloride, comprising the following raw materials by weight: 80 parts of vinyl chloride; 10 parts of calcium carbonate; 5 parts of aluminum hydroxide; 7 parts of zinc ions; 3 parts of gelatin; 7 parts of zinc powder; 13 parts of acid ester; 14 parts of graphene.

[0042] By storing the PVC polyvinyl chloride produced by the formula, and placing the PVC polyvinyl chloride in a humid place, it is observed how many days after the PVC polyvinyl chloride is invented.

Embodiment 2

[0044] A PVC polyvinyl chloride, comprising the following raw materials in parts by weight: 80-95 parts of vinyl chloride; 13 parts of calcium carbonate; 8 parts of aluminum hydroxide; 10 parts of zinc ions; 5 parts of gelatin; 11 parts of zinc powder; 16 parts of diformate; 19 parts of graphene.

[0045] By storing the PVC polyvinyl chloride produced by the formula, and placing the PVC polyvinyl chloride in a humid place, it is observed how many days after the PVC polyvinyl chloride is invented.

Embodiment 3

[0047] A PVC polyvinyl chloride, comprising the following raw materials in parts by weight: 80-95 parts of vinyl chloride; 16 parts of calcium carbonate; 12 parts of aluminum hydroxide; 14 parts of zinc ions; 8 parts of gelatin; 15 parts of zinc powder; 20 parts of diformate; 24 parts of graphene.

[0048] By storing the PVC polyvinyl chloride produced by the formula, and placing the PVC polyvinyl chloride in a humid place, it is observed how many days after the PVC polyvinyl chloride is invented.

[0049] Table I

[0050] month Example 1 Example 2 Embodiment 3 3-4 no mold no mold no mold 9-12 mildew appears no mold mildew appears 5-8 mildew appears no mold no mold

[0051] According to the above examples, the important proportions in Example 2 are the best, and the PVC polyvinyl chloride of this formula has the best use effect.

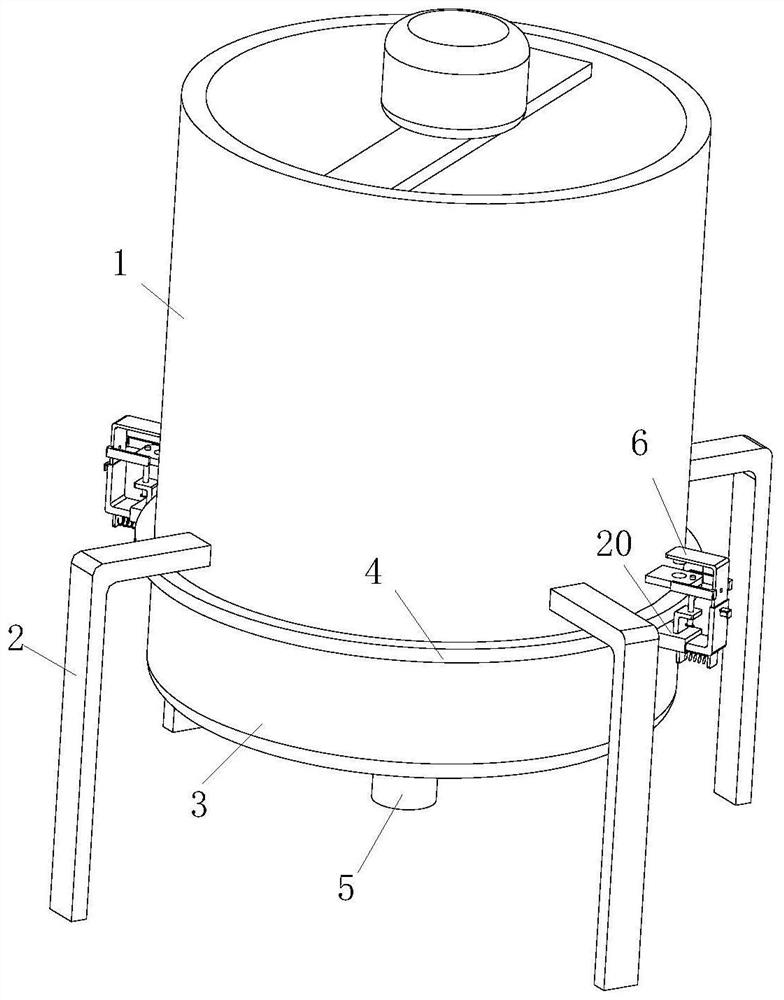

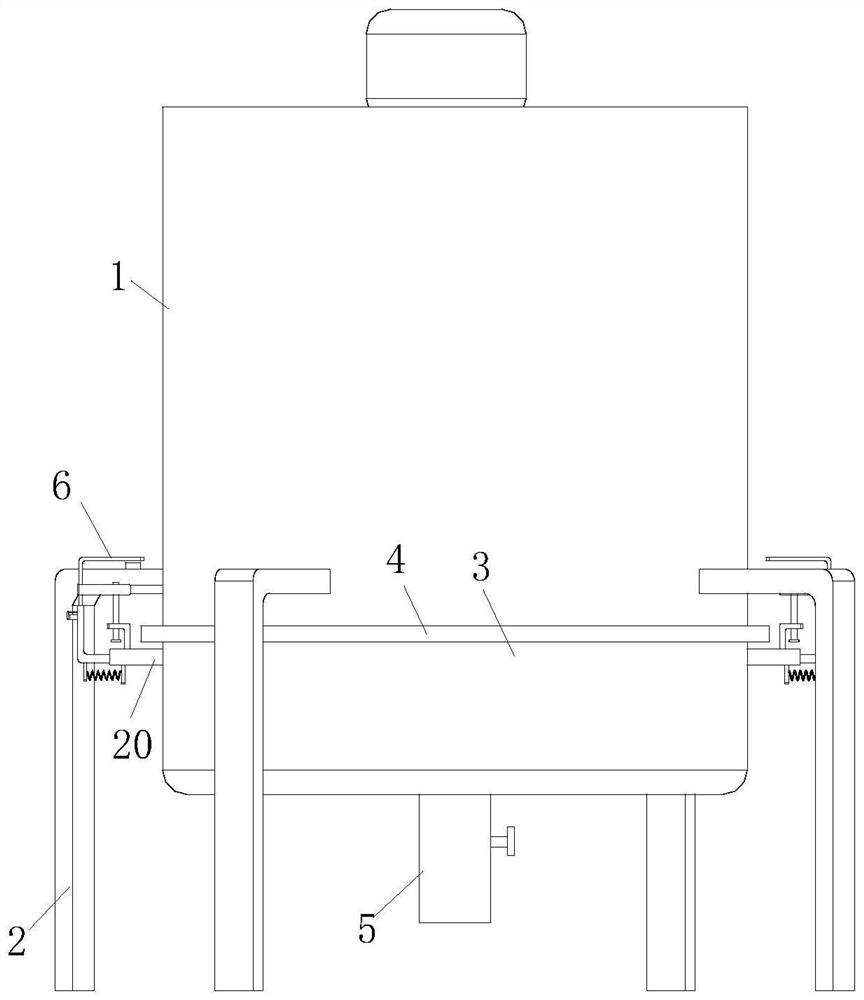

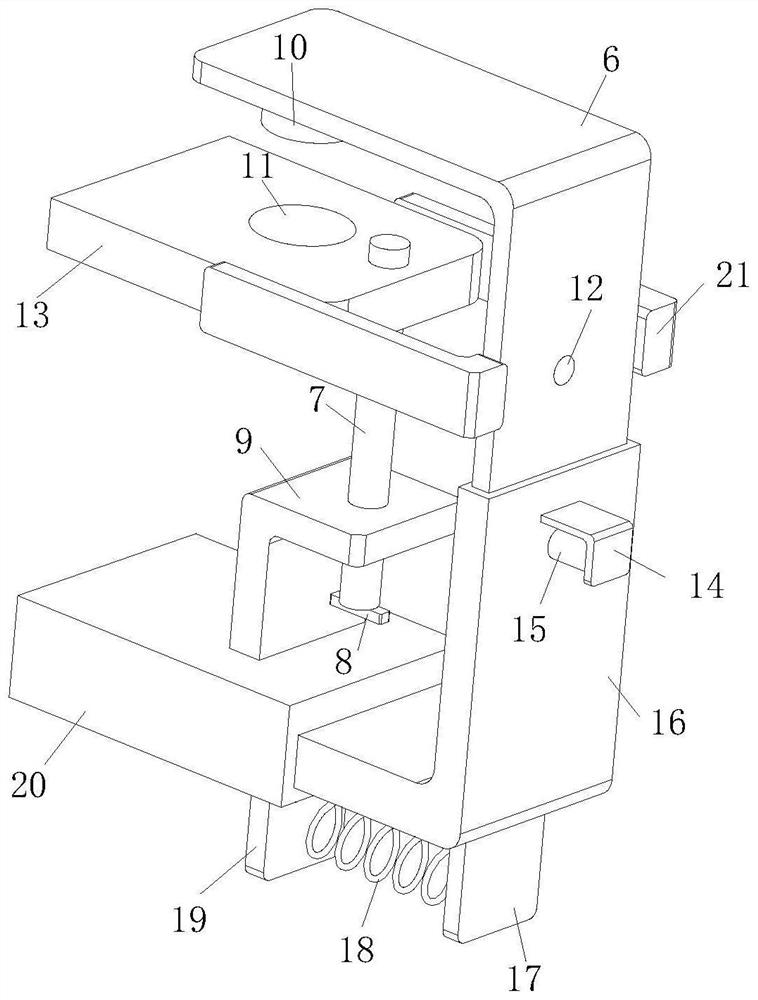

[0052] see Figure 1-5 Shown, a kind of PVC polyvinyl chloride, comprises the raw material of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com