Antibacterial plastic rattan and preparation method thereof

An antibacterial plastic and rattan technology, applied in the field of plastic processing, can solve the problems of easy adhesion of bacteria on the user's body, easy breeding of bacteria, mildew of plastic rattan, etc., to improve thermal stability and light stability, improve Polarity, antibacterial long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] (1) Weigh UHMWPE, LDPE, glycidyl methacrylate and initiator for banburying according to regulations, and set the banburying condition to 180°C to obtain graft copolymer;

[0044](2) Weigh L-cysteine according to regulations, dissolve it in water to form an L-cysteine aqueous solution, weigh nano-zinc oxide and add it into the L-cysteine solution, mix well, and then carry out the mixed solution centrifuging, and drying the obtained particles to obtain L-cysteine-modified nano-zinc oxide;

[0045] (3) Mix and melt extrude the graft copolymer obtained in the above steps, the modified nano-zinc oxide, accelerator, antioxidant, and ultraviolet absorber, and perform cooling, shearing, and granulation after extrusion.

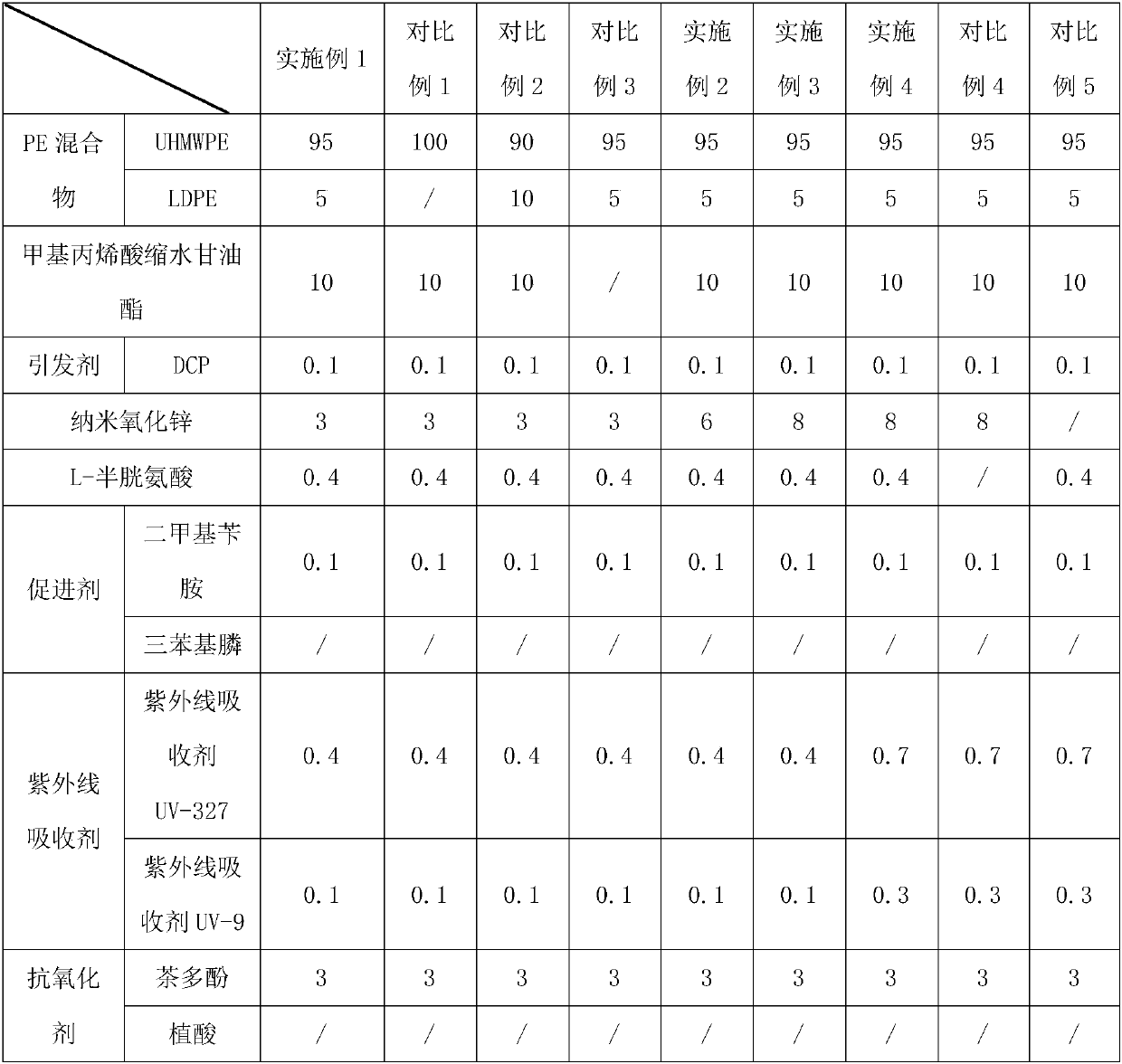

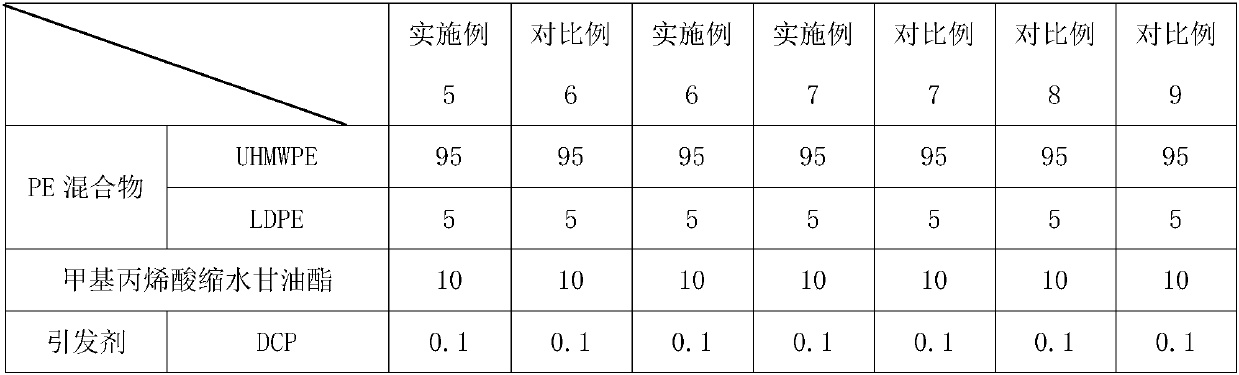

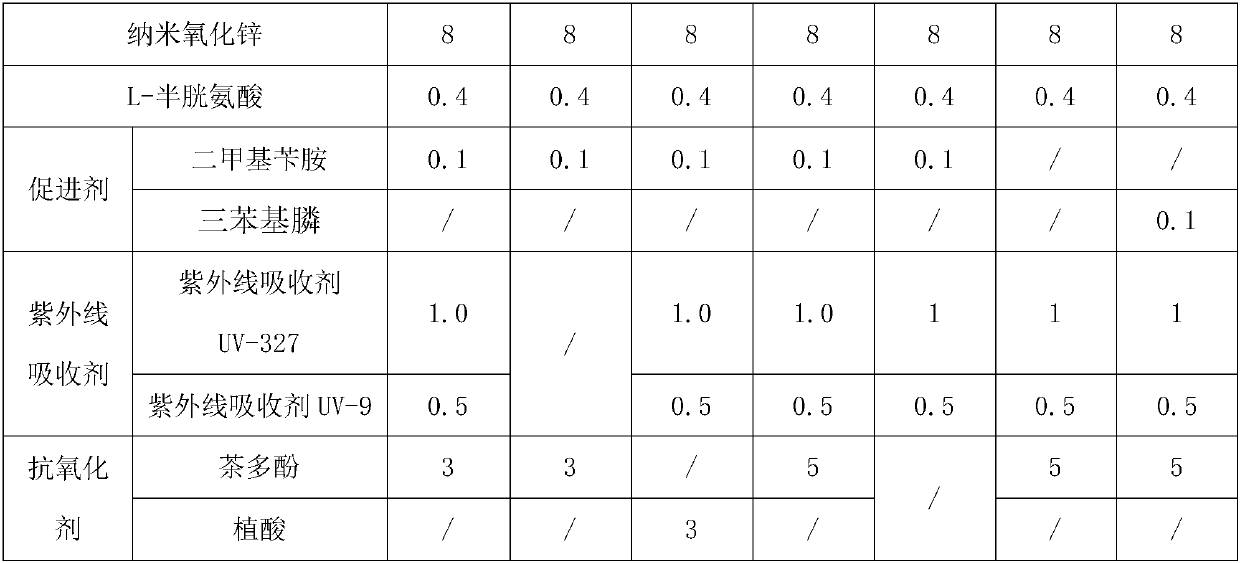

[0046] Examples 1-4 and Comparative Examples 1-5 adopted the above-mentioned method to prepare aging-resistant antibacterial plastic rattan, and the raw material consumption is shown in Table 1.

[0047] Table 1 embodiment 1-4 and comparative example 1-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com