Woven composite material reinforcing cable, composite material spoke and manufacturing method of composite material spoke

A technology of composite materials and manufacturing methods, which is applied in the manufacture of braided fabrics, spoked wheels, and wheels, can solve the problems of low overall strength and low reliability, and achieve simple weaving process, strong integrity, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A braided composite material reinforcing cord, comprising yarn 1 and core 2.

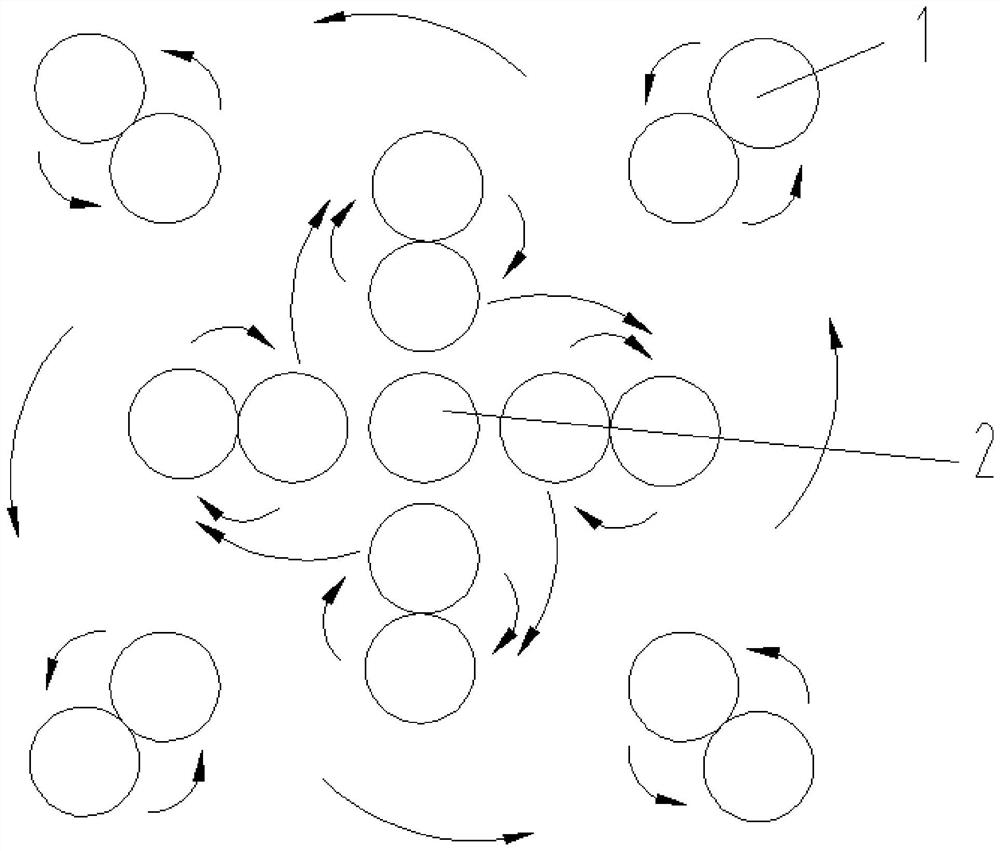

[0042] see figure 1 , the yarn surrounds the core, and is woven around and wraps the core in an interwoven manner to form a yarn wrapping layer.

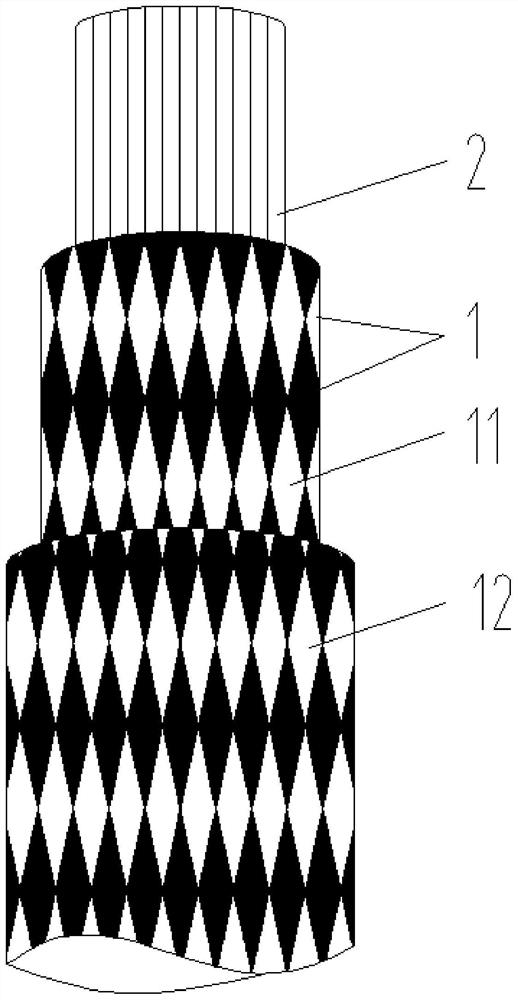

[0043] In this embodiment, the circumference of the core 2 has two layers of yarn covering layers, and the rotation directions of the yarns 1 of the two layers of yarn covering layers are opposite to the winding direction of the core 2, so that the rotational torque is offset. see figure 2 , from the inside to the outside are the adjacent first yarn covering layer 11 and the second yarn covering layer 12, the ends of the two yarn covering layers are flush, figure 2 In order to clearly illustrate the two overlapping layers, the ends of the yarn groups of the two layers of yarn covering layers are cut off in turn to show a ladder shape.

[0044] see figure 1 , the yarn covering layer includes eight strands of yarns 1 evenly distributed on the p...

Embodiment 2

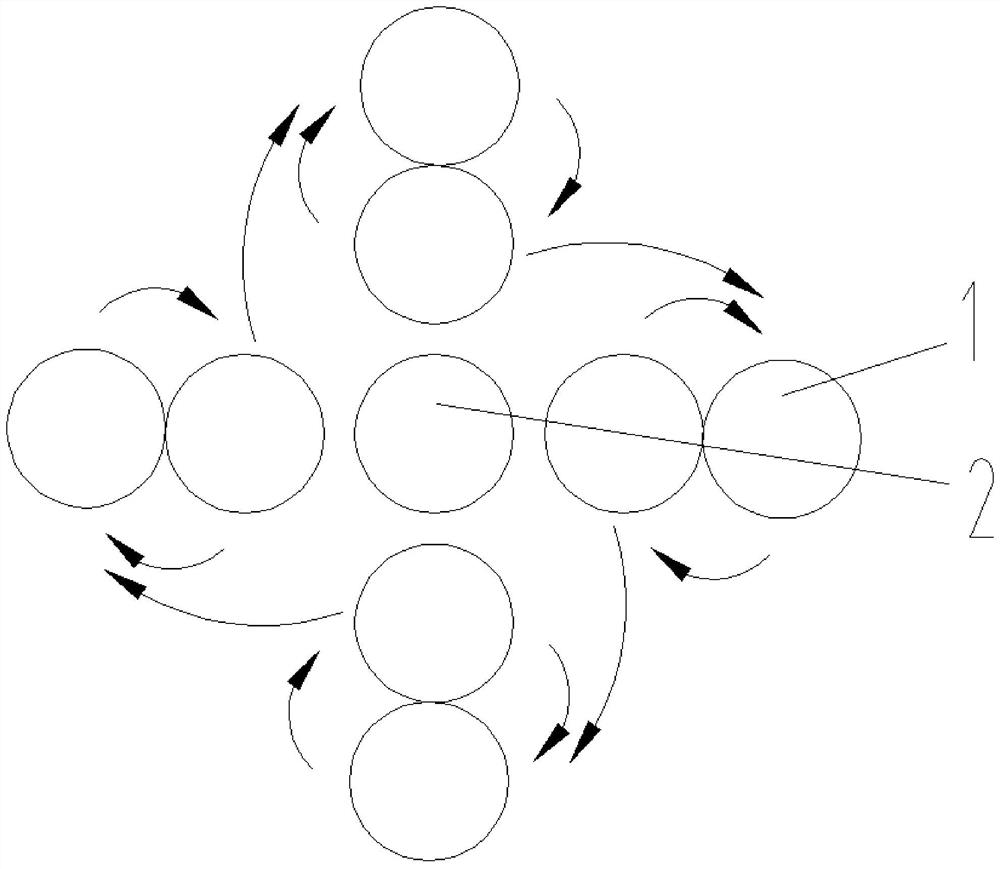

[0049] The difference from the first embodiment is that in this embodiment, the yarn covering layer is only one layer, please refer to image 3 .

Embodiment 3

[0051] A carbon fiber spoke adopts the braided composite material reinforcing cable proposed in the first embodiment, wherein the core 2 is a carbon fiber rod, and the tensile performance of the carbon fiber rod is improved by weaving yarn 1 around the carbon fiber rod. In this embodiment, the carbon fiber rods are flat spokes, and the rotation directions of the yarns 1 of the two adjacent yarn coating layers are opposite, so that the rotational torsion force is offset, and the parallelism of the planes on both sides of the flat spoke is ensured from the shape.

[0052] In other embodiments, the core 2 may also be of other composite materials to make composite spokes, such as glass fiber spokes.

[0053] Experiment 1: The tensile failure comparison experiment was carried out on the large-angle woven flat spokes obtained in this example and the metal spoke products of the same specifications of other brands on the market, and the tensile failure comparison experiment table 1 was...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap