Method for preventing oxidative degradation of black phosphorus nanosheet and application of black phosphorus nanosheet

A technology of oxidative degradation and nanosheets, applied in chemical instruments and methods, phosphorus compounds, phosphorus, etc., can solve the problems of loss of catalytic performance, photocatalytic performance, and reduction of the number of surface catalytic active sites, so as to improve the stability of black phosphorus, Stable, efficient and controllable photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

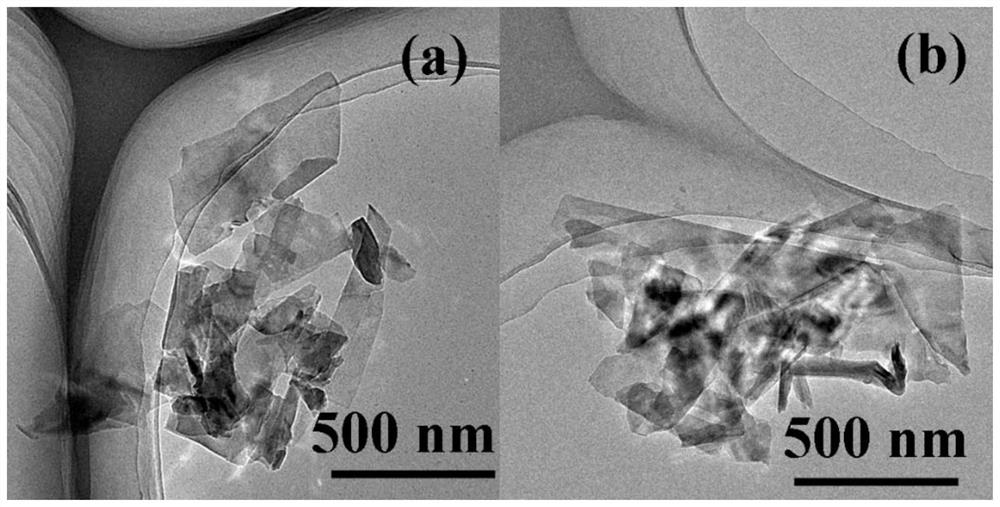

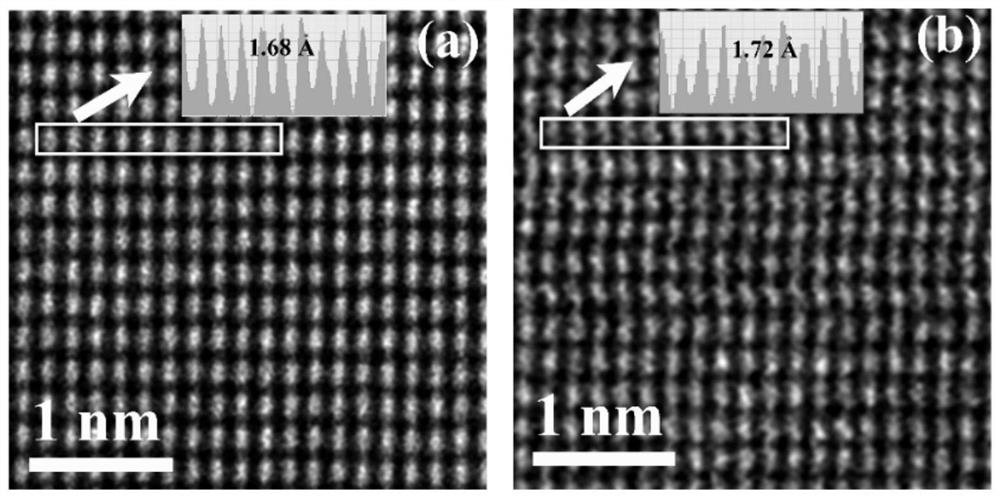

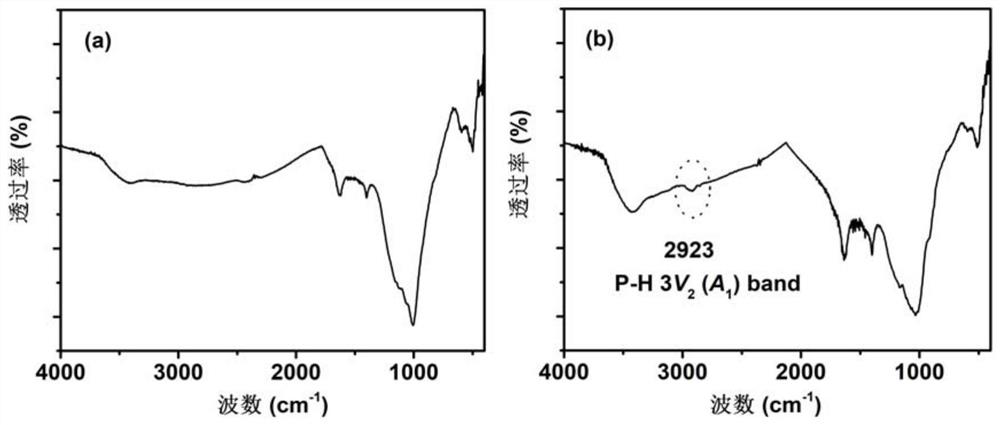

[0052] 1. Preparation of black phosphorus nanosheets

[0053] Black phosphorus nanosheets: Add 100 mg of black phosphorus powder to 1000 ml of N-methylpyrrolidone solvent, use a cell crusher to perform ultrasonic peeling for 6-10 hours, and centrifuge the obtained black phosphorus nanosheet suspension (6000 r / min) for 10 minutes, collect the supernatant, then centrifuge (10,000 r / min) for 20 minutes, collect the solid, and finally wash with ethanol 5 times to remove N-methylpyrrolidone After that, it was put into a vacuum oven at 40° C. for 12 hours to obtain black phosphorus nanosheets.

[0054] Hydrogenated black phosphorus nanosheets: 20 mg of black phosphorus nanosheet powder was transferred into a tube furnace under a mixed atmosphere of argon and hydrogen (argon flow rate: 50 mL / min, hydrogen flow rate: 5 mL / min) from room temperature The temperature was raised to 350°C at 5°C / min, and then kept for 4 hours; after the reaction was completed, it was naturally cooled to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com