All-plastic tail door outer plate material low in linear expansion coefficient and easy to bond and preparation method of all-plastic tail door outer plate material

A low linear expansion, plate material technology, applied in the field of full plastic tailgate outer plate material and its preparation, can solve the problems of large difference in linear expansion coefficient, large product size gap, poor bonding performance, etc., and achieve low linear expansion coefficient. , Improve the bonding strength, reduce the effect of linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

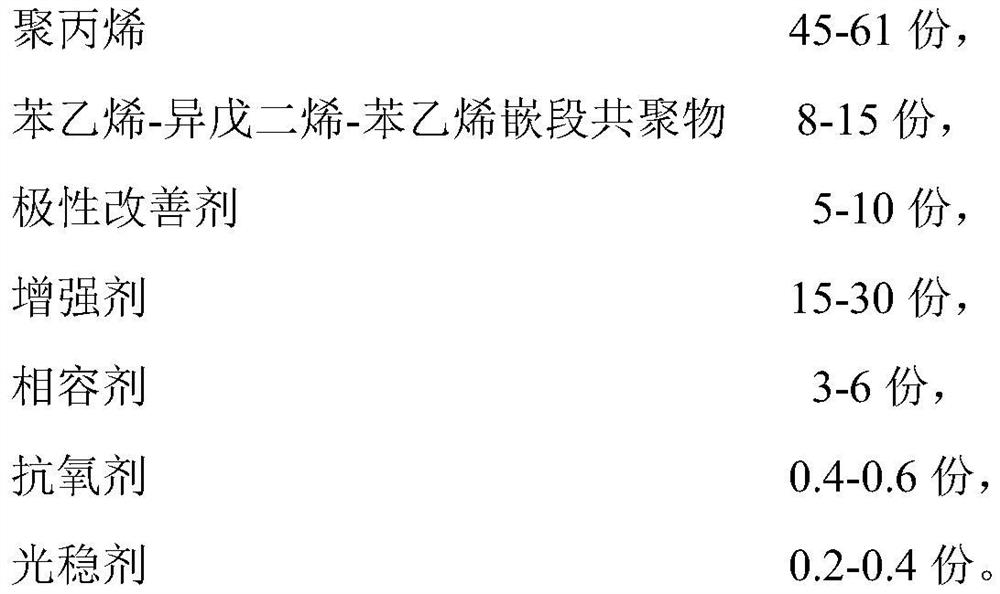

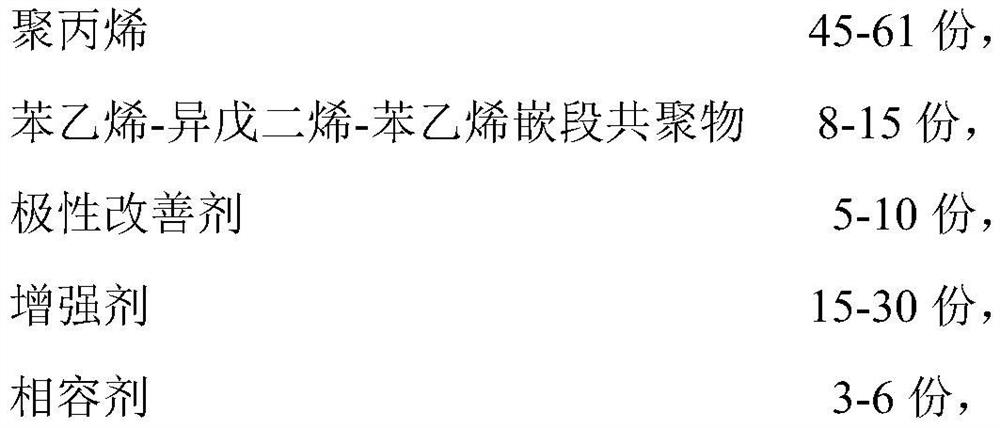

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of an all-plastic tailgate outer panel material with low linear expansion coefficient and easy bonding, the steps are as follows:

[0040] (1) Weigh 61 parts of polypropylene, 8 parts of styrene-isoprene-styrene block copolymer, 10 parts of nitrile rubber, 15 parts of modified magnesium salt whiskers, 6 parts of PP grafted maleic anhydride , 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168 and 0.2 part of light stabilizer 3808PP5, put into a high-speed mixer and mixed to obtain a mixture.

[0041] (2) adding the mixture into a twin-screw extruder and extruding, the extruded strip is cooled to room temperature through a circulating water tank, and dried by a blower, and then enters a pelletizer for granulation to obtain the low linear expansion coefficient of the present invention. Tailgate outer panel material. The length-diameter ratio of the twin-screw extruder is 48:1, and the temperature of each section of the barrel of the twin-screw ...

Embodiment 2

[0043] A preparation method of an all-plastic tailgate outer panel material with low linear expansion coefficient and easy bonding, the steps are as follows:

[0044] (1) Weigh 57 parts of polypropylene, 10 parts of styrene-isoprene-styrene block copolymer, 8 parts of nitrile rubber, 20 parts of modified magnesium salt whiskers, 5 parts of PP grafted maleic anhydride , 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168 and 0.2 part of light stabilizer 3808PP5, put into a high-speed mixer and mixed to obtain a mixture.

[0045] (2) adding the mixture into a twin-screw extruder and extruding, the extruded strip is cooled to room temperature through a circulating water tank, dried by a blower, and then granulated into a pelletizer to obtain the low linear expansion coefficient of the present invention and an easy-to-bond all-plastic Tailgate outer panel material. The length-diameter ratio of the twin-screw extruder is 48:1, and the temperature of each section of the barre...

Embodiment 3

[0047] A preparation method of an all-plastic tailgate outer panel material with low linear expansion coefficient and easy bonding, the steps are as follows:

[0048](1) Weigh 53 parts of polypropylene, 12 parts of styrene-isoprene-styrene block copolymer, 6 parts of nitrile rubber, 25 parts of modified magnesium salt whiskers, 4 parts of PP grafted maleic anhydride , 0.2 part of antioxidant 1010, 0.3 part of antioxidant 168 and 0.3 part of light stabilizer 3808PP5, put into a high-speed mixer and mixed to obtain a mixture.

[0049] (2) adding the mixture into a twin-screw extruder and extruding, the extruded strip is cooled to room temperature through a circulating water tank, and dried by a blower, and then enters a pelletizer for granulation to obtain the low linear expansion coefficient of the present invention. Tailgate outer panel material. The length-diameter ratio of the twin-screw extruder is 48:1, and the temperature of each section of the barrel of the twin-screw e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com