Device and method for analyzing impurities in hydrogen isotope gas

A hydrogen isotope and impurity analysis technology, applied in the field of gas chromatography analysis, can solve the problems of high analysis results and difficult effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] for calibrating instruments 4 He sensitivity

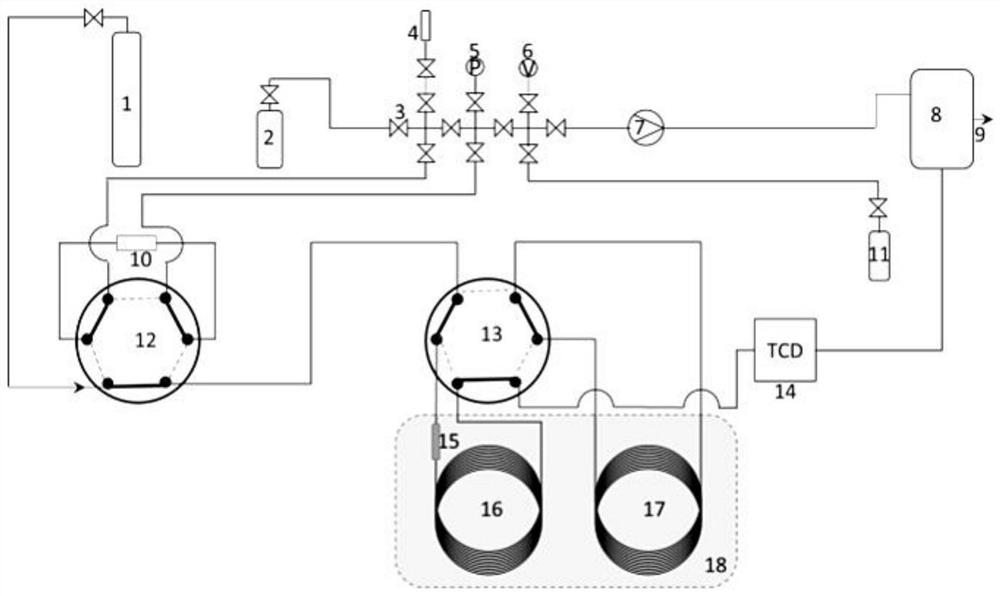

[0075](1), set the temperature of the chromatographic column box 18 and the temperature of the thermal conductivity detector 14 to 200°C, close the second six-way valve 13 (at this time, the first chromatographic column 16 is communicated with the thermal conductivity detector 14), use a high Purging the hydrogen purifier 15 and the chromatographic column with pure argon, the purging time is not less than 4 hours;

[0076] (2), cooling the chromatographic column and the hydrogen purifier 15 to 30°C, and the temperature of the thermal conductivity detector 14 to 70°C;

[0077] (3), will 4 The standard gas source 2 (the main component is argon) with a He content of 0.1% is as follows figure 2 The position shown is connected to the vacuum sampling system;

[0078] (4) Evacuate the chromatograph pipeline and perform vacuum leak detection to ensure air tightness;

[0079] (5), observe the baseline, open the first six-way v...

Embodiment 2

[0088] for calibrating instruments 3 He sensitivity.

[0089] (1), set the temperature of the chromatographic column box 18 and the temperature of the thermal conductivity detector 14 to 200°C, close the second six-way valve 13 (at this time, the first chromatographic column 16 is communicated with the thermal conductivity detector 14), use a high Purging the hydrogen purifier 15 and the chromatographic column with pure argon, the purging time is not less than 4 hours;

[0090] (2), cooling the chromatographic column and the hydrogen purifier 15 to 30°C, and the temperature of the thermal conductivity detector 14 to 70°C;

[0091] (3), will be pure 3 He gas is used as the standard gas source 2, according to the appendix figure 2 The position shown is connected to the vacuum sampling system;

[0092] (4) Evacuate the chromatograph pipeline and perform vacuum leak detection to ensure air tightness;

[0093] (5), observe the baseline, open the first six-way valve 12 after t...

Embodiment 3

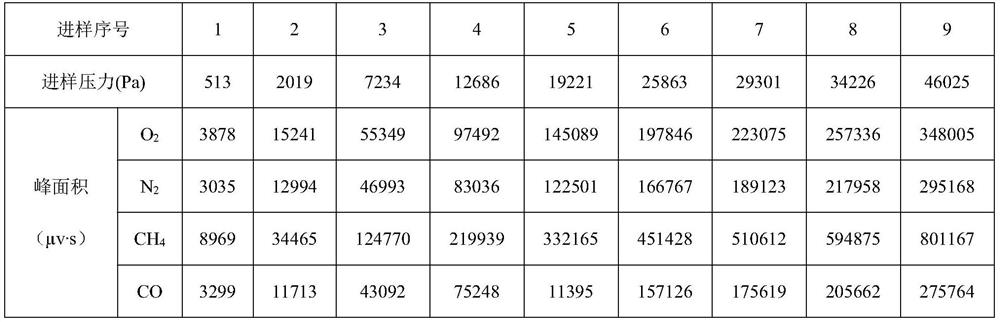

[0103] O to calibrate the instrument 2 , N 2 , CH 4 , CO sensitivity

[0104] (1) The temperature of the chromatographic column box 18 and the temperature of the thermal conductivity detector 14 are both set to 200°C to 250°C, and the second six-way valve 13 is opened (at this time, the second chromatographic column 17 is communicated with the thermal conductivity detector 14), The second chromatographic column 17 is purged with high-purity argon, and the purge time is not less than 4 hours;

[0105] (2), cooling the chromatographic column and the hydrogen purifier 15 to 30°C, and the temperature of the thermal conductivity detector 14 to 70°C;

[0106] (3), the main component is hydrogen, O 2 , N 2 , CH 4 , standard gas with CO content of 1.00%, 1.00%, 1.00% and 1.00% respectively, according to the attached figure 2 The position shown is connected to the vacuum sampling system;

[0107] (4) Evacuate the chromatograph pipeline and perform vacuum leak detection to ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com