An embedded double-sided heat dissipation mosfet module package structure

A technology of double-sided heat dissipation and module packaging, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of low integration and large volume, so as to improve integration, solve technical problems, and improve heat dissipation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

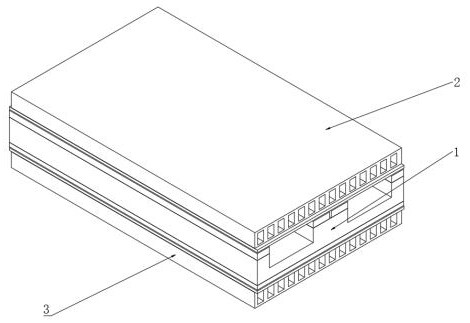

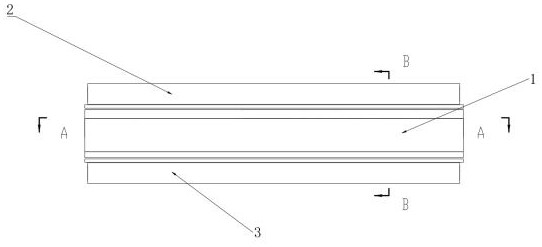

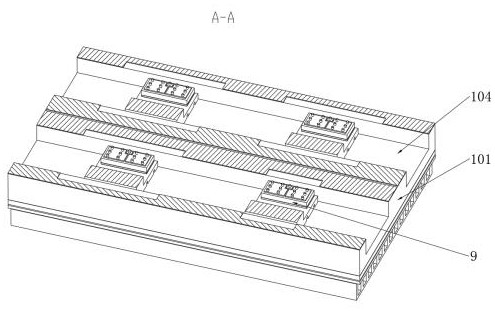

[0029] like Figures 1 to 9 As shown, an embedded double-sided heat dissipation MOSFET module packaging structure includes a DBC combination layer 1 and a MOSFET chip 9. The DBC combination layer 1 includes a DBC ceramic layer 101, and both sides of the upper surface of the DBC ceramic layer 101 are integrally provided with installation Intervals 104, square grooves 103 are respectively opened inside each installation interval 104, and MOSFET chips 9 are installed in each square groove 103 through the first copper sheet group 10 and the second copper sheet group 11, and the DBC composite layer 1 is up and down The surfaces are respectively mounted with an upper heat sink 2 and a lower heat sink 3 through a thermal interface material layer 6 . By embedding the MOSFET chip 9 in the DBC combination layer 1, the volume occupied by the MOSFET chip 9 is reduced, the overall integration of the module is improved, and the upper heat sink 2 and the lower heat sink 3 are respectively ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com