Ink

A technology of ink and inkjet printing, applied in the direction of ink, duplication/marking method, printing, etc., can solve the problems of printing quality reduction, printing surface damage, etc., and achieve the effect of excellent rubbing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] 138 parts by mass of deionized water was put into a reaction vessel equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, a thermometer, and a dropping funnel, and the temperature was raised to 80° C. while blowing in nitrogen gas.

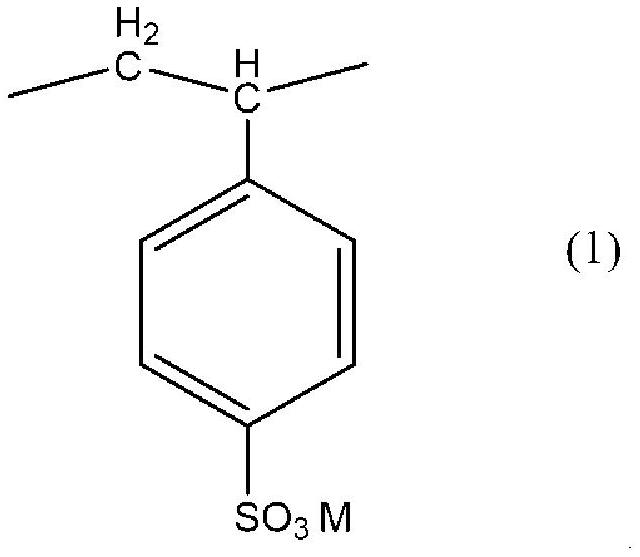

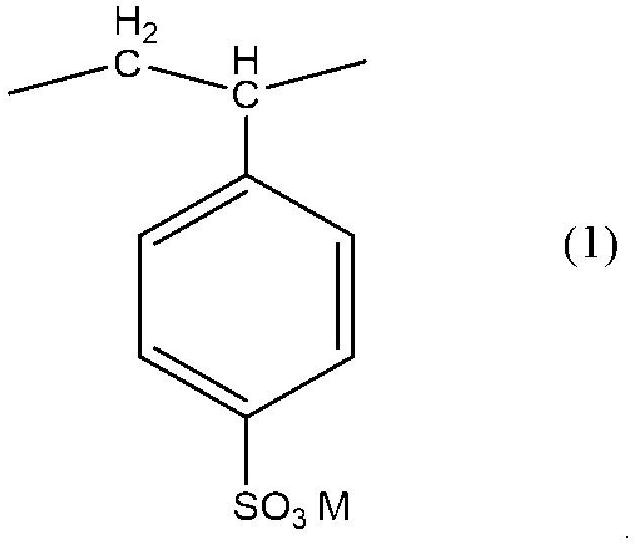

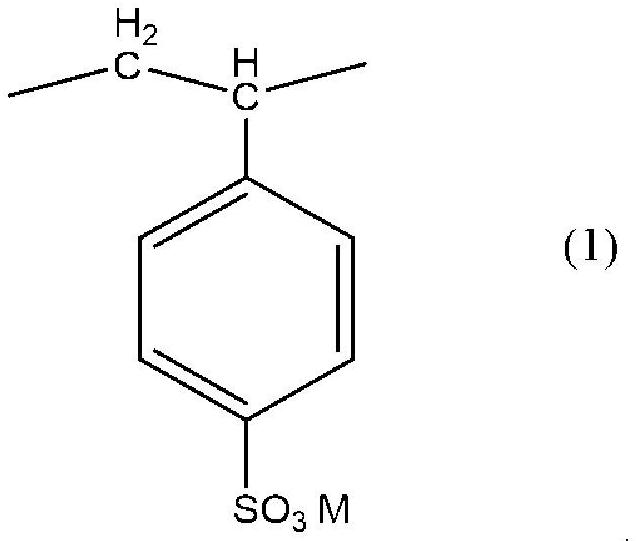

[0102] Next, 2 parts by mass of methacrylic acid, 2 parts by mass of sodium styrene sulfonate, and 0.05 part by mass of thiomalic acid were added, and 5 parts by mass of a 10 mass % aqueous sodium persulfate solution was added at 80° C. to initiate polymerization.

[0103] After the temperature in the polymerization vessel was maintained at 80° C. for 1 hour, the contents of the polymerization vessel were cooled, and ammonia water was mixed to obtain an aqueous solution (I-1) of the polymer (A-1).

[0104] Next, 50 parts by mass of n-butyl acrylate, 30 parts by mass of methyl methacrylate, and methyl methacrylate were added dropwise to the aqueous solution (I-1) of the polymer (A-1) adjusted to 80° C. over 4 hours. 1...

Embodiment 2

[0116] 138 parts by mass of deionized water was put into a reaction vessel equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, a thermometer, and a dropping funnel, and the temperature was raised to 80° C. while blowing in nitrogen gas.

[0117] Next, 4.5 parts by mass of methacrylic acid, 5.6 parts by mass of sodium styrene sulfonate, and 0.15 part by mass of thiomalic acid were added, and 5 parts by mass of a 10 mass % ammonium persulfate aqueous solution was added at 80° C. to initiate polymerization.

[0118] After the temperature in the polymerization vessel was maintained at 80° C. for 1 hour, the contents of the polymerization vessel were cooled, and ammonia water was mixed to obtain an aqueous solution (I-2) of the polymer (A-2).

[0119] To the aqueous solution (I-2) of the above-mentioned polymer (A-2), 40 parts by mass of ethyl acrylate, 30 parts by mass of methyl methacrylate and 30 parts by mass of 2-hydroxyethyl methacrylate were added dr...

Embodiment 3

[0125] 138 parts by mass of deionized water was put into a reaction vessel equipped with a stirrer, a reflux cooling tube, a nitrogen introduction tube, a thermometer, and a dropping funnel, and the temperature was raised to 80° C. while blowing in nitrogen gas.

[0126] Next, 4.5 parts by mass of methacrylic acid, 5.6 parts by mass of sodium styrene sulfonate, and 0.15 part by mass of thiomalic acid were added, and 5 parts by mass of a 10 mass % ammonium persulfate aqueous solution was added at 80° C. to initiate polymerization.

[0127] After the temperature in the polymerization vessel was maintained at 80° C. for 1 hour, the contents of the polymerization vessel were cooled, and ammonia water was mixed to obtain an aqueous solution (I-3) of the polymer (A-3).

[0128] To the aqueous solution (I-3) of the above-mentioned polymer (A-3), 32 parts by mass of ethyl acrylate, 23 parts by mass of n-butyl acrylate, 5 parts by mass of methyl methacrylate and methacrylic acid were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com