A real-time detection method and system for universal welding arc starting continuity

A real-time detection and continuity technology, applied to welding equipment, welding accessories, manufacturing computing systems, etc., can solve the problems of hidden defects, short arc starting continuity, and many welding joints, so as to achieve high practical value and increase network The number of channels and the effect of deepening the number of network layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings, and the technical solutions of the present invention will be described more clearly and completely.

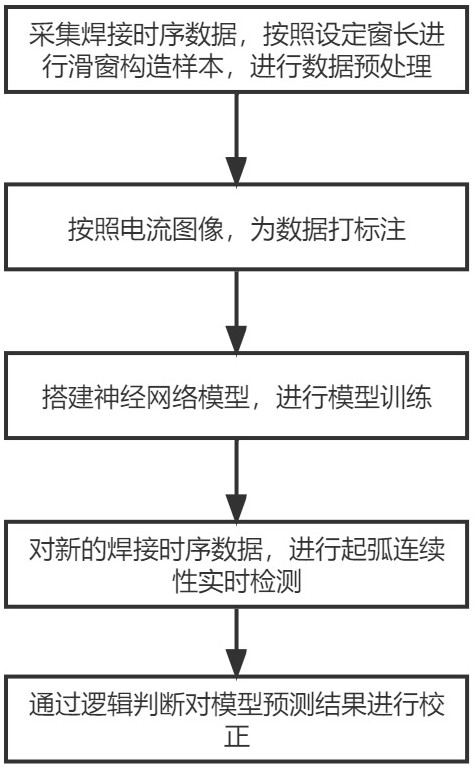

[0039] like figure 1 Shown is a universal real-time detection method for arc starting continuity of welding, which includes the following steps:

[0040] Step 1: Data annotation;

[0041] Step 1.1: Use the collected high-frequency current data to construct a sliding window sample according to the window length window_size. In this embodiment, window_size=1000.

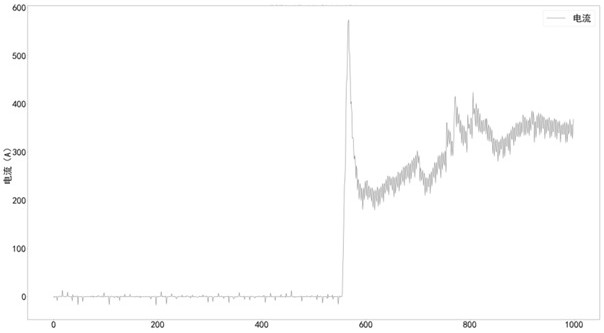

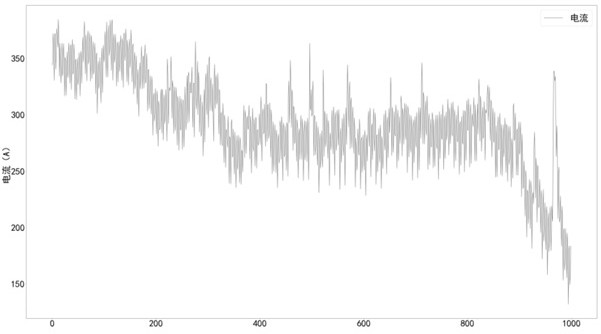

[0042] Step 1.2: According to the current image (eg Figure 2-4 Shown is a complete arc starting continuity event, including three processes of arc starting, welding and arc extinction) for sample marking;

[0043] The time point when the arc starts in the sample is recorded as start_point, and the time point when the arc is extinguished is recorded as end_point, so as to generate the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com