High-comfort polyurethane sponge as well as preparation method and application product thereof

A polyurethane sponge and comfort technology, applied in bandages, absorbent pads, medical science and other directions, can solve the problems of difficult to absorb and retain wound exudate, excessively wet wound environment, difficult tissue healing, etc., to reduce extensibility and Permanent deformation, high liquid retention rate, and the effect of solving poor comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention provides the preparation method of the high-comfort polyurethane sponge as described above, comprising the following steps:

[0038] Mixing and reacting the polyether polyol and toluene diisocyanate until the NCO value is stable to obtain a polyurethane sponge material A; mixing water, a crosslinking agent and a catalyst to obtain a polyurethane sponge material B;

[0039] After mixing and foaming material A and material B in an appropriate proportion, the high-comfort polyurethane sponge is obtained.

[0040] In specific embodiments of the present invention, the preparation method of described polyurethane sponge comprises:

[0041] According to the weight ratio of the composition, under the protection of nitrogen, anhydrous polyether polyol, toluene diisocyanate and lubricant can be reacted at 40-120°C until the NCO value is stable to obtain polyurethane sponge A material; Use deionized water), crosslinking agent, catalyst, por...

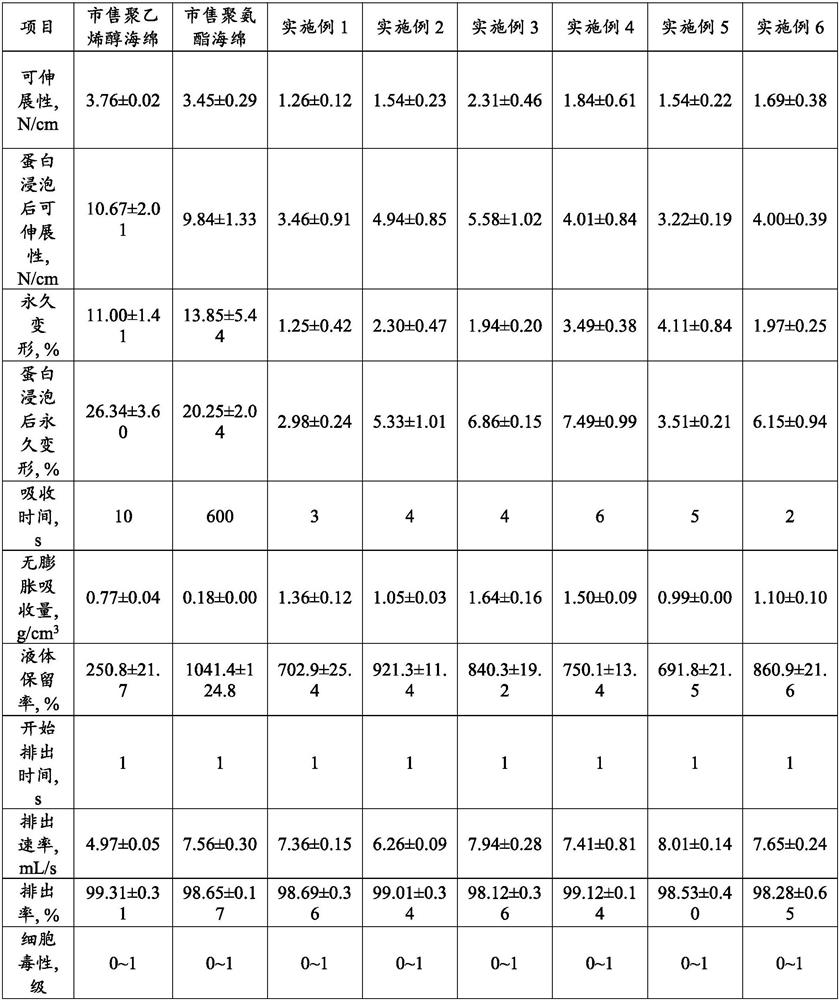

Embodiment 1

[0049] Under nitrogen protection, in 100g of anhydrous polyether triol (ethylene oxide: propylene oxide is 30:70, number average molecular weight is 5000), add 46.73g of toluene diisocyanate (80% by mass percentage content of 2,4-toluene diisocyanate and 20% by mass of the mixture of 2,6-toluene diisocyanate), stirring and reacting at 80°C until the NCO value is stable, to obtain polyurethane sponge A material; 95.54g of deionized Water, 74.96g of glycerin, 3.82g of triethylenediamine, 15.94g of polyoxyethylene and polyoxypropylene block polymer (L-64), 4.92g of C8-10 fatty alcohol polyoxyethylene ether, 6.38g Polyoxyethylene sorbitan fatty acid ester, 2.41g of 3-aminopropyltrimethoxysilane and 1.25g of color paste were mixed uniformly at 20°C to obtain polyurethane sponge B material; 40g of the above-mentioned A material and 55.82g of material B was mechanically stirred at 15°C to foam freely, the rotating speed was 1500rpm, and the time was 30s. After foaming, a high-comfort...

Embodiment 2

[0051] Under nitrogen protection, in 100g of anhydrous polyether triol (ethylene oxide: propylene oxide is 75:25, number average molecular weight is 4000), add 40.12g of toluene diisocyanate (80% by mass content of 2,4-toluene diisocyanate and 20% by mass of 2,6-toluene diisocyanate), stirred and reacted at 95°C until the NCO value was stable to obtain polyurethane sponge A material; 98.06g of deionized Water, 52.07g of glycerin, 22.89g of trimethylolpropane, 4.03g of triethylenediamine, 5.61g of polyoxyethylene and polyoxypropylene block polymer (L-62), 12.05g of allyl Alcohol polyoxyalkyl ether, 5.01g of C8-10 fatty alcohol polyoxyethylene ether, 7.38g of sorbitan fatty acid ester, 1.98g of 3-aminopropyltrimethoxysilane and 1.25g of color paste in Mix evenly at 40°C to obtain polyurethane sponge material B; mechanically stir 40g of the above-mentioned material A and 57.33g of material B at 25°C to foam freely at a speed of 1200rpm for 30s, and obtain high-comfort polyurethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com