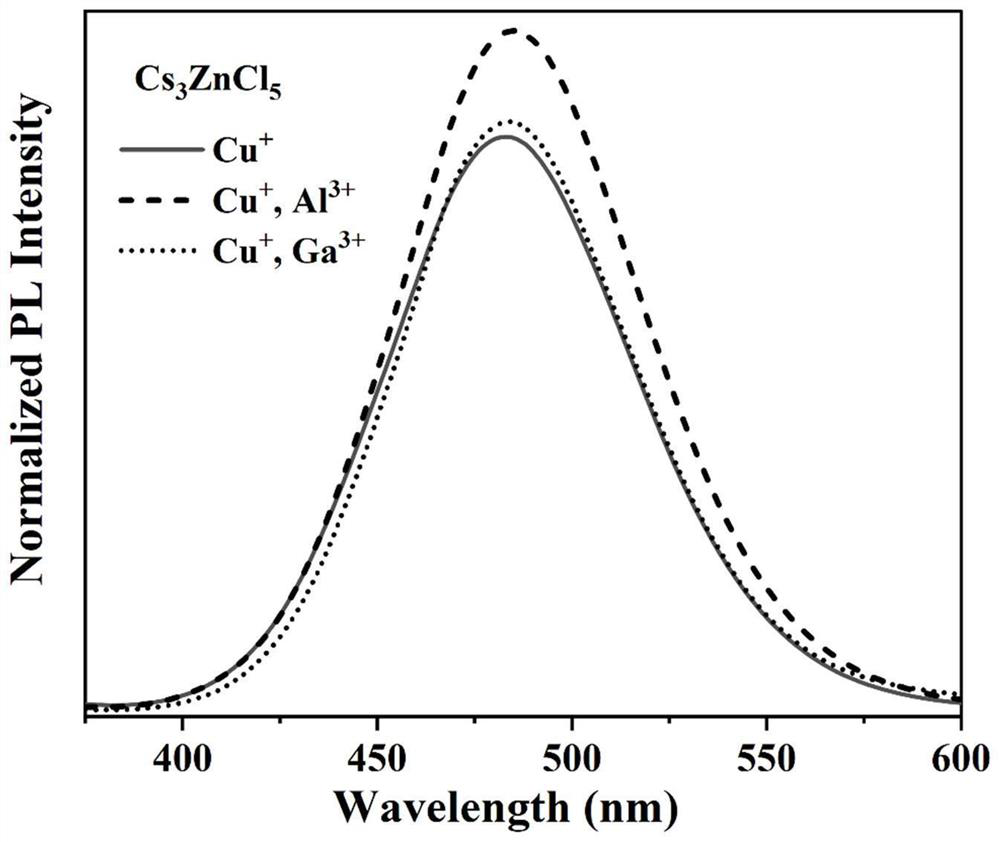

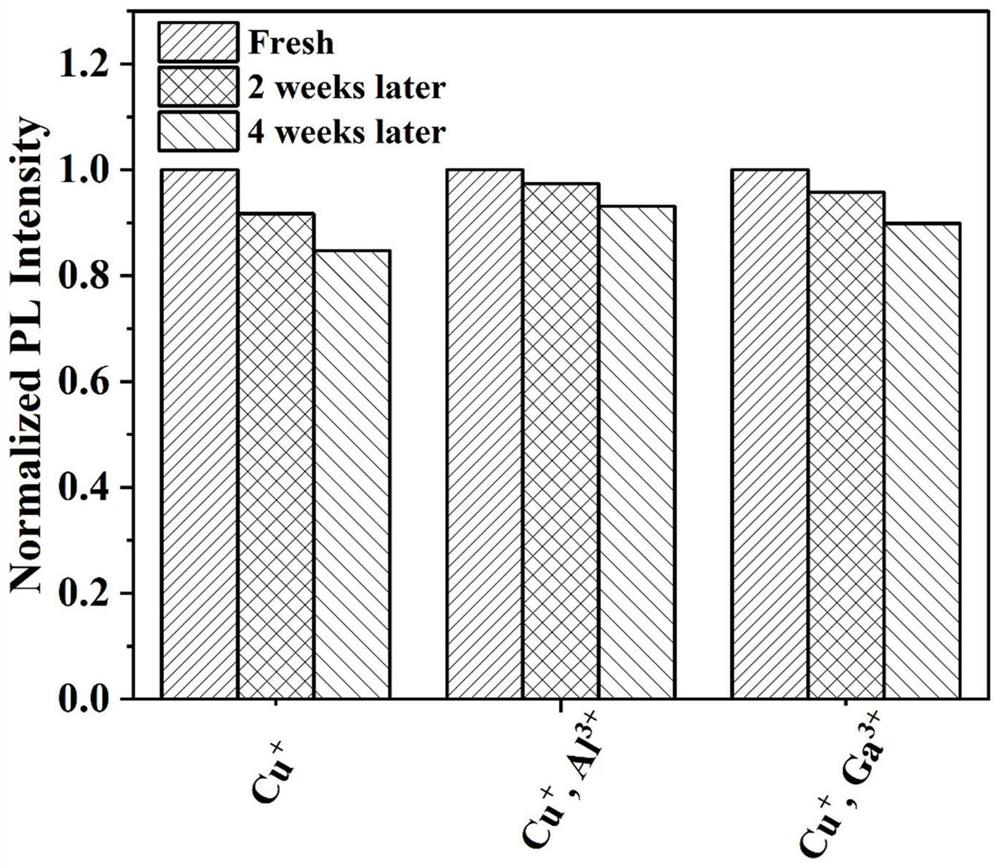

Zero-dimensional zinc-based halide luminescent material and preparation method thereof

A luminescent material, zero-dimensional zinc technology, applied in luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve problems such as low luminous efficiency, and achieve high luminous efficiency, high crystallinity, and air stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 3 mmol of CsCl, 0.99 mmol of ZnCl 2 , 0.005 mmol of CuCl, 0.005 mmol of AlCl 3 , pour it into a 25ml polytetrafluoroethylene reactor lining, add 3ml methanol, stir for at least 30min, mix the reaction materials evenly, add 0.05ml oleylamine, continue stirring for 10min, take out the stirring bar. With the reactor seal that contains above-mentioned reaction raw material, it is put into 180 o C in the blast oven, heat preservation for 12 h. After the reaction, when the reaction kettle was naturally lowered to room temperature, the reaction kettle was opened, the supernatant was discarded, 4ml of n-butanol solution was added and washed by centrifugation at 8000 rpm for 2 min, and the washing was repeated twice, then the n-butanol was replaced with Use the same washing method as n-hexane to wash once. Place the washed samples at 60 o C dried in a vacuum oven for 12 hours, and after the temperature dropped to room temperature, the samples were collected in reagent ...

Embodiment 2

[0048] Weigh 3 mmol of CsCl, 0.95 mmol of ZnCl 2 , 0.025 mmol of CuCl, 0.025 mmol of AlCl 3 , pour it into a 25ml polytetrafluoroethylene reactor lining, add 3ml methanol, stir for at least 30min, mix the reaction materials evenly, add 0.25ml oleylamine, continue stirring for 10min, take out the stirring bar. With the reactor seal that contains above-mentioned reaction raw material, it is put into 180 o C in the blast oven, heat preservation for 12 h. After the reaction, when the reaction kettle was naturally lowered to room temperature, the reaction kettle was opened, the supernatant was discarded, 4ml of n-butanol solution was added and washed by centrifugation at 8000 rpm for 2 min, and the washing was repeated twice, then the n-butanol was replaced with Use the same washing method as n-hexane to wash once. Place the washed samples at 60 o C dried in a vacuum oven for 12 hours, and after the temperature dropped to room temperature, the samples were collected in reagent ...

Embodiment 3

[0050] Weigh 3 mmol of CsCl, 0.9 mmol of ZnCl 2 , 0.05 mmol of CuCl, 0.05 mmol of AlCl 3 , pour it into a 25ml polytetrafluoroethylene reactor lining, add 3ml methanol, stir for at least 30min, mix the reaction materials evenly, add 0.5ml oleylamine, continue stirring for 10min, take out the stirring bar. With the reactor seal that contains above-mentioned reaction raw material, it is put into 180 o C in the blast oven, heat preservation for 12 h. After the reaction, when the reaction kettle was naturally lowered to room temperature, the reaction kettle was opened, the supernatant was discarded, 4ml of n-butanol solution was added and washed by centrifugation at 8000 rpm for 2 min, and the washing was repeated twice, then the n-butanol was replaced with Use the same washing method as n-hexane to wash once. Place the washed samples at 60 o C dried in a vacuum oven for 12 hours, and after the temperature dropped to room temperature, the samples were collected in reagent bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com