Vanadium-doped strontium titanate nanofiber and preparation method and application thereof

A nanofiber, strontium titanate technology, applied in nanotechnology, nanotechnology, fiber chemical characteristics, etc., can solve problems such as poor electrical conductivity, and achieve the effect of improving piezoelectric performance, strong piezoelectric catalytic activity, and improving piezoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

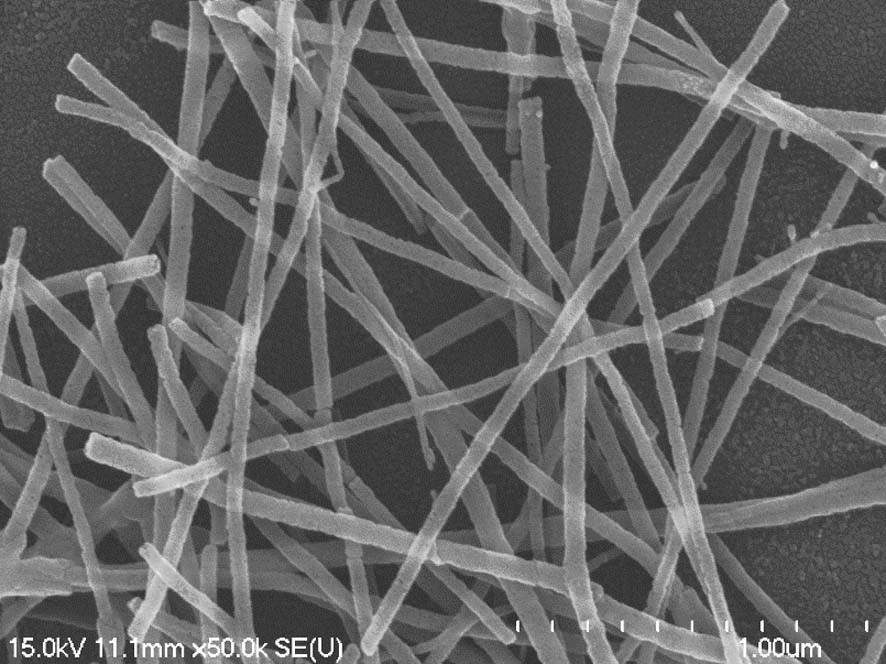

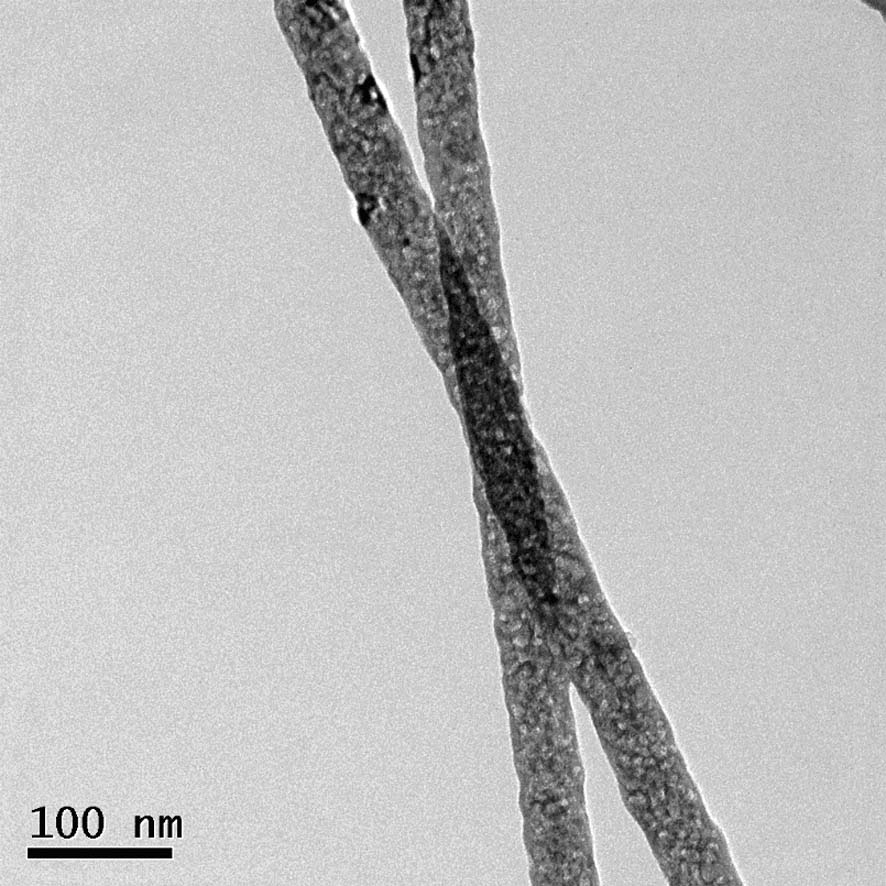

[0025] Vanadium-doped strontium titanate nanofiber piezoelectric material (0.25 mol% V-SrTiO 3 NFs) preparation: firstly, 1 mmol of strontium nitrate and 0.0025 mmol of vanadyl acetylacetonate were dissolved in a solution containing 1.5 mL of ethanol, 1.5 mL of N,N-dimethylformamide, 1.5 mL of acetic acid, 1.5 mL of deionized water and tetratitanate Butyl ester solution, stirred until clear, then added 0.5g of polyvinylpyrrolidone, stirred at room temperature for 12 hours, injected the obtained transparent light yellow solution into the syringe for electrospinning, electrospinning equipment The vertical distance between the nozzle tip and the grounded stainless steel receiver and the electrospinning voltage were 15 cm and 15 kV, respectively; o C / min heating rate from room temperature to 550 o C, and then calcined for 3 hours to obtain vanadium-doped strontium titanate nanofiber piezoelectric material (0.25mol% V-SrTiO 3 NFs), wherein the molar ratio of strontium nitrate, ...

Embodiment 2

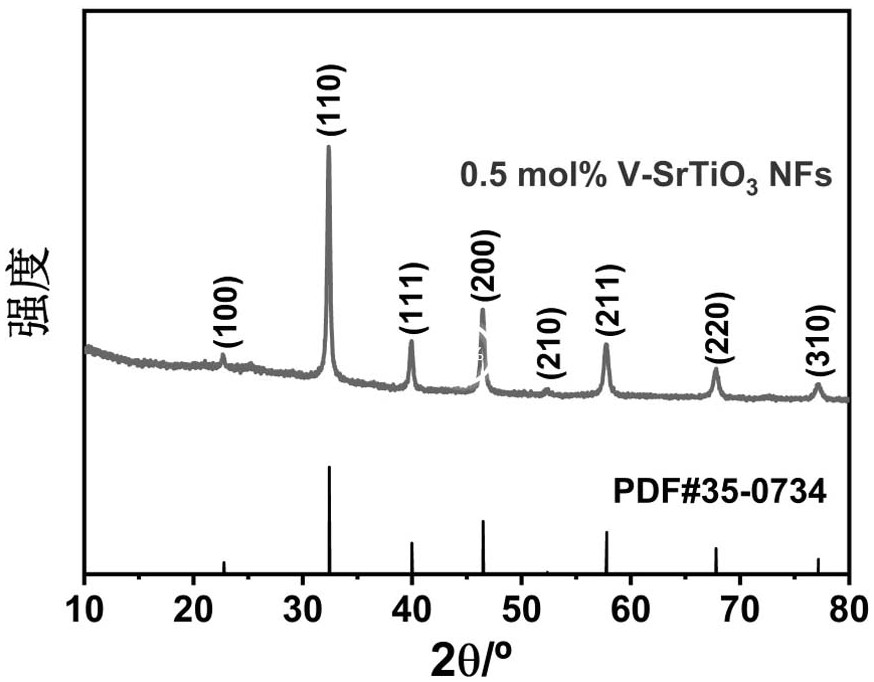

[0027] Vanadium-doped strontium titanate nanofiber piezoelectric material (0.5 mol% V-SrTiO 3 NFs) preparation: firstly, 1 mmol of strontium nitrate and 0.005 mmol of vanadyl acetylacetonate were dissolved in a solution containing 1.5 mL of ethanol, 1.5 mL of N,N-dimethylformamide, 1.5 mL of acetic acid, 1.5 mL of deionized water and tetratitanate Butyl ester solution, stirred until clear, then added 0.5 g of polyvinylpyrrolidone, stirred at room temperature for 12 hours, injected the obtained transparent light yellow solution into the syringe for electrospinning, electrospinning equipment The vertical distance between the nozzle tip and the grounded stainless steel receiver and the electrospinning voltage were 15 cm and 15 kV, respectively; o C / min heating rate from room temperature to 550 o C, and then calcined for 3 hours to obtain the vanadium-doped strontium titanate nanofiber piezoelectric material (0.5mol% V-SrTiO 3NFs), wherein the molar ratio of strontium nitrate, ...

Embodiment 3

[0029] Vanadium-doped strontium titanate nanofiber piezoelectric material (1.0 mol% V-SrTiO 3 NFs) preparation: firstly, 1 mmol of strontium nitrate and 0.01 mmol of vanadyl acetylacetonate were dissolved in a solution containing 1.5 mL of ethanol, 1.5 mL of N,N-dimethylformamide, 1.5 mL of acetic acid, 1.5 mL of deionized water and tetratitanate Butyl ester solution. After stirring until clear, 0.5 g of polyvinylpyrrolidone was added thereto, and after stirring at room temperature for 12 hours, the obtained transparent light yellow solution was injected into a syringe. The vertical distance between the nozzle tip of the electrospinning device and the grounded stainless steel receiver and the electrospinning voltage were 15 cm and 15 kV, respectively. After electrospinning, the obtained product was subjected to 2 o C / min heating rate from room temperature to 550 o C, and then calcined for 3 hours, the vanadium-doped strontium titanate nanofiber piezoelectric material (1.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com