Nano silicon dioxide suspension, preparation method and cement-based grouting material containing suspension

A technology of nano-silica and silica, applied in the field of cement-based grouting materials, can solve problems affecting product fluidity, weak structure, large specific surface area, etc., achieve enhanced chloride ion permeability and frost resistance, and improve interface Situation, effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

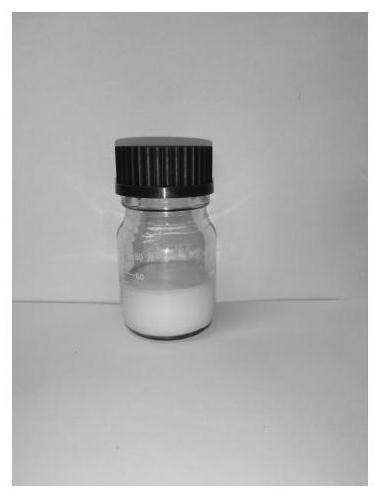

Image

Examples

Embodiment 1

[0023] The preparation method of nano-silica suspension of the present invention comprises the following steps:

[0024] In step 1, the silica nanoparticles are placed in a muffle furnace, heated to 300° C. and then calcined for 2 hours, then heated to 900° C. and calcined for 4 hours, and naturally cooled to room temperature to obtain activated silica nanoparticles;

[0025] Step 2, add 0.1 part of water reducing agent, 0.1 part of coupling agent and 0.01 part of calcium hydroxide to 5 parts of water in sequence, stir evenly, then add 1 part of activated silica nanoparticles to it, stir evenly to obtain nanometer two. Silica suspending agent.

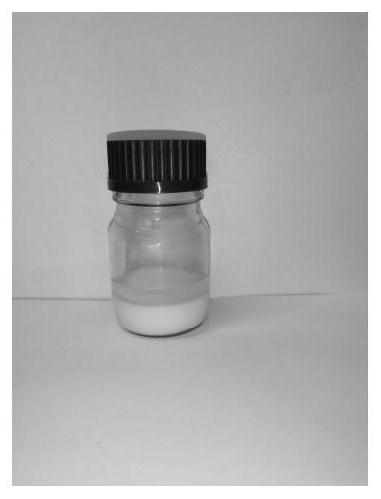

Embodiment 2

[0027] The preparation method of nano-silica suspension of the present invention comprises the following steps:

[0028] In step 1, the silica nanoparticles are placed in a muffle furnace, heated to 300° C. and then calcined for 2 hours, then heated to 900° C. and calcined for 4 hours, and naturally cooled to room temperature to obtain activated silica nanoparticles;

[0029] Step 2, add 0.3 part of water reducing agent, 0.1 part of coupling agent and 0.02 part of calcium hydroxide to 10 parts of water in turn, stir evenly, then add 1 part of activated silica nanoparticles to it, stir evenly to obtain nano-dioxide. Silica suspending agent.

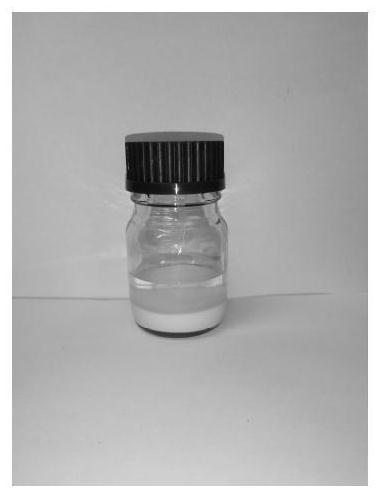

Embodiment 3

[0031] The preparation method of nano-silica suspension of the present invention comprises the following steps:

[0032] In step 1, the silica nanoparticles are placed in a muffle furnace, heated to 300° C. and then calcined for 2 hours, then heated to 900° C. and calcined for 4 hours, and naturally cooled to room temperature to obtain activated silica nanoparticles;

[0033] Step 2, add 0.5 part of water reducing agent, 0.1 part of coupling agent and 0.02 part of calcium hydroxide to 10 parts of water in turn, stir evenly, then add 1 part of activated silica nanoparticles to it, stir evenly to obtain nanometer two. Silica suspending agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com