Process for preparing steel slag cement concrete by using converter steel slag

A technology of cement concrete and converter steel slag, which is applied to compounds of group 4/14 elements of the periodic table, sustainable waste treatment, solid waste management, etc., can solve the overall safety threat, concrete structure cracking, and plastic deformation capacity of steel slag concrete low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment is a preparation method of a concrete reinforcing agent, comprising the following steps:

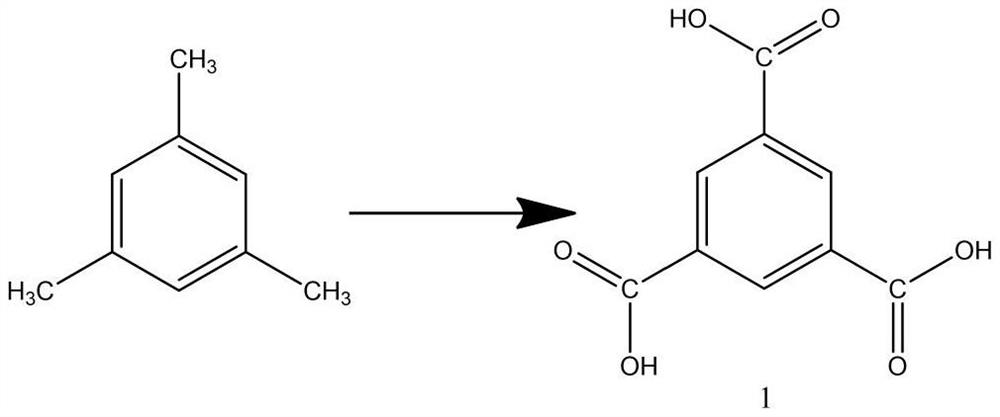

[0045] S1: add 0.1mol mesitylene, 0.5mol glacial acetic acid and 1.0g cobalt acetate into the reaction kettle, and under the condition that the temperature is 200°C and the stirring rate is 500r / min, air is introduced while stirring, and the air introduction rate is controlled 0.5m 3 / h, after constant temperature stirring for 4h, the reaction product was cooled to room temperature, filtered, and the reaction product was distilled to dryness to obtain Intermediate 1;

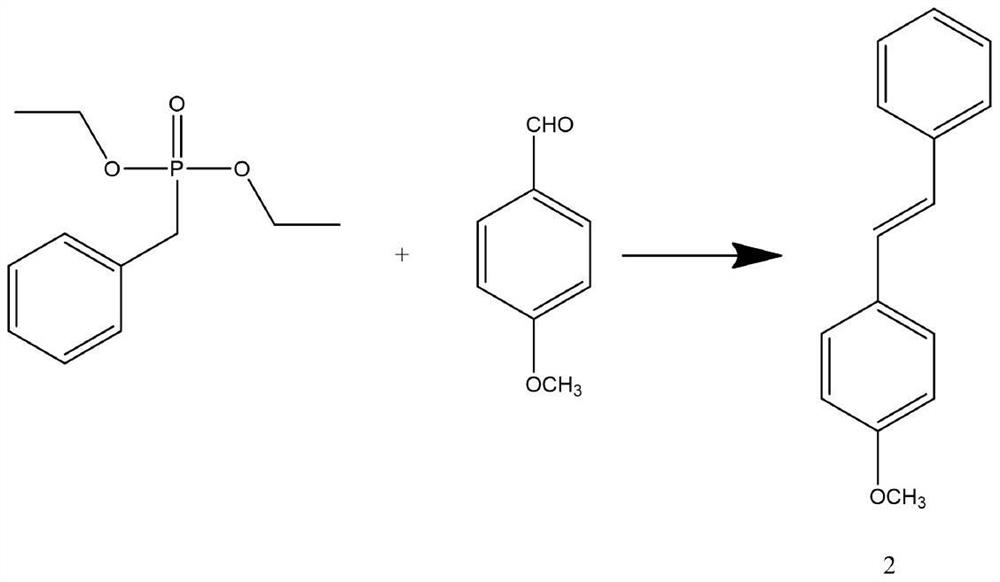

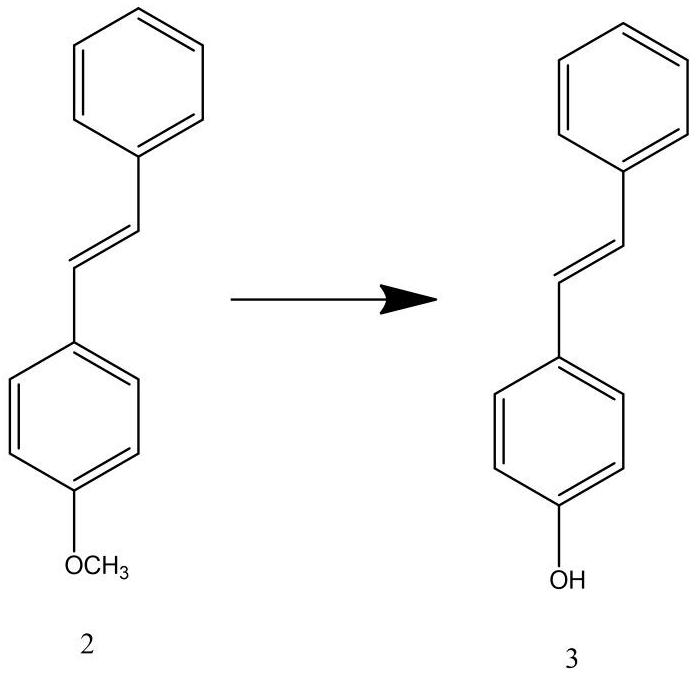

[0046] S2: Add 0.1 mol of diethyl phenylphosphonate and 100 mL of N,N-dimethylformamide into a three-necked flask equipped with a stirrer, an air pipe and a constant pressure dropping funnel, and the stirring rate is 200 r / min. Stir for 10 min under conditions, then cool down to below 0 °C, add 0.1 mol of sodium methoxide, and then stir for 10 min at a temperature of 0 °C and a stirring rate ...

Embodiment 2

[0052] The present embodiment is a preparation method of a concrete reinforcing agent, comprising the following steps:

[0053] S1: add 0.1mol mesitylene, 0.5mol glacial acetic acid and 1.5g cobalt acetate into the reaction kettle, at a temperature of 220°C and a stirring rate of 800r / min, the air is fed while stirring, and the air feeding rate is controlled 0.7m 3 / h, the reaction product was cooled to room temperature after stirring at a constant temperature for 5 h, filtered, and the reaction product was distilled to dryness to obtain Intermediate 1;

[0054] S2: Add 0.1 mol of diethyl phenylphosphonate and 100 mL of N,N-dimethylformamide into a three-necked flask equipped with a stirrer, an air tube and a constant pressure dropping funnel, and the stirring rate is 300 r / min. Stir for 20 min under conditions, then cool down to below 0 °C, add 0.1 mol of sodium methoxide, then stir for 20 min at a temperature of 5 °C and a stirring rate of 500 r / min, and then add 0.115 mol ...

Embodiment 3

[0060] The present embodiment is a process for preparing steel slag cement concrete using converter steel slag, comprising the following steps:

[0061] Step 1: Weigh 30 parts of cement, 10 parts of steel slag, 15 parts of sand, 10 parts of crushed stone, 8 parts of concrete reinforcing agent from Example 1, 25 parts of water, and 0.2 part of naphthalene-based superplasticizer according to parts by weight , 0.1 part of diethylenetriamine and 0.1 part of polydimethylsiloxane, for use;

[0062] Step 2: Add 1 / 2 of the water and the concrete reinforcing agent into the mixer for stirring, add cement, steel slag, sand, and gravel to continue stirring after stirring evenly, and obtain mixture A after stirring evenly;

[0063] Step 3: adding the remaining 1 / 2 of the water naphthalene-based superplasticizer, diethylenetriamine and polydimethylsiloxane into the mixer for stirring, and after stirring evenly, mixture B is obtained;

[0064] Step 4: Add the mixture B into the mixture A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com