Environment-friendly odorless asphalt mixture and preparation method thereof

An asphalt mixture, an environmentally friendly technology, applied in the field of concrete asphalt, can solve the problems of poor crack resistance, limited use of asphalt concrete materials, general crack resistance, etc., and achieve the effect of stable low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

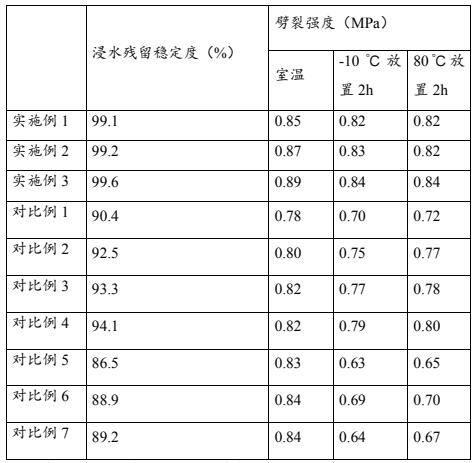

Examples

preparation example Construction

[0023] The preparation method of the fiber modifier of the present embodiment is:

S101: Mix 5-10 parts of silane coupling agent, 1-5 parts of sodium phenolsulfonate and 10-20 parts of water, then add 2-6 parts of chitosan and 1-3 parts of sodium alginate, continue to mix thoroughly , obtain silane coupling agent modification liquid;

S102: adding 10-20 parts of aluminum silicate fibers to 45-55 parts of silane coupling agent modification solution to prepare a fiber coupling agent compound solution;

S103: mixing 5-10 parts of carbon nanotubes and 1-5 parts of graphene, and then adding 10-20 parts of an aqueous hydrochloric acid solution with a mass fraction of 5-9% to prepare a modified solution;

S104: The modification liquid and the fiber coupling agent compound liquid are stirred and reacted according to the weight ratio of 1: (5~9) and mixed, the reaction is completed, washed with water and dried to obtain the fiber modification agent.

[0024] The silane coupling agent...

Embodiment 1

The present invention of this embodiment provides an environment-friendly odor-free asphalt mixture, comprising the following raw materials in parts by weight:

10 parts of asphalt, 30 parts of cement, 5 parts of limestone mineral powder, 4 parts of fiber modifier, 2 parts of stearic acid modified magnesium oxide body, 1 part of deodorant, and 3 parts of ceramic fine powder.

[0031] The particle size of the limestone ore powder in this embodiment is 2mm; the particle size of the ceramic micropowder is 20um; and the deodorant is 3-ethylhexylaldehyde.

[0032] The preparation method of the fiber modifier of the present embodiment is:

S101: Mix 5 parts of silane coupling agent, 1 part of sodium phenolsulfonate and 10 parts of water, then add 2 parts of chitosan and 1 part of sodium alginate, and continue to mix thoroughly to obtain a modified liquid of silane coupling agent;

S102: adding 10 parts of aluminum silicate fibers to 45 parts of silane coupling agent modification sol...

Embodiment 2

The present invention of this embodiment provides an environment-friendly odor-free asphalt mixture, comprising the following raw materials in parts by weight:

20 parts of asphalt, 45 parts of cement, 10 parts of limestone mineral powder, 9 parts of fiber modifier, 5 parts of stearic acid modified magnesium oxide body, 3 parts of deodorant, and 6 parts of ceramic fine powder.

[0040] The particle size of the limestone ore powder in this embodiment is 2.5mm; the particle size of the ceramic micropowder is 30um; the deodorant is 3-ethylhexylaldehyde.

[0041] The preparation method of the fiber modifier of the present embodiment is:

S101: Mix 0 parts of silane coupling agent, 5 parts of sodium phenolsulfonate and 20 parts of water, then add 6 parts of chitosan and 3 parts of sodium alginate, and continue to mix thoroughly to obtain a modified liquid of silane coupling agent;

S102: adding 20 parts of aluminum silicate fibers to 55 parts of silane coupling agent modification s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com