Water-based inorganic zinc-rich coating easy to construct as well as preparation method and application of water-based inorganic zinc-rich coating

An inorganic zinc-rich coating, water-based technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of fast drying speed, easy powdering and falling off of the paint film, insufficient leveling, etc., and achieve improvement Anti-sagging, excellent leveling and initial water resistance, excellent anti-settling effect of zinc powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

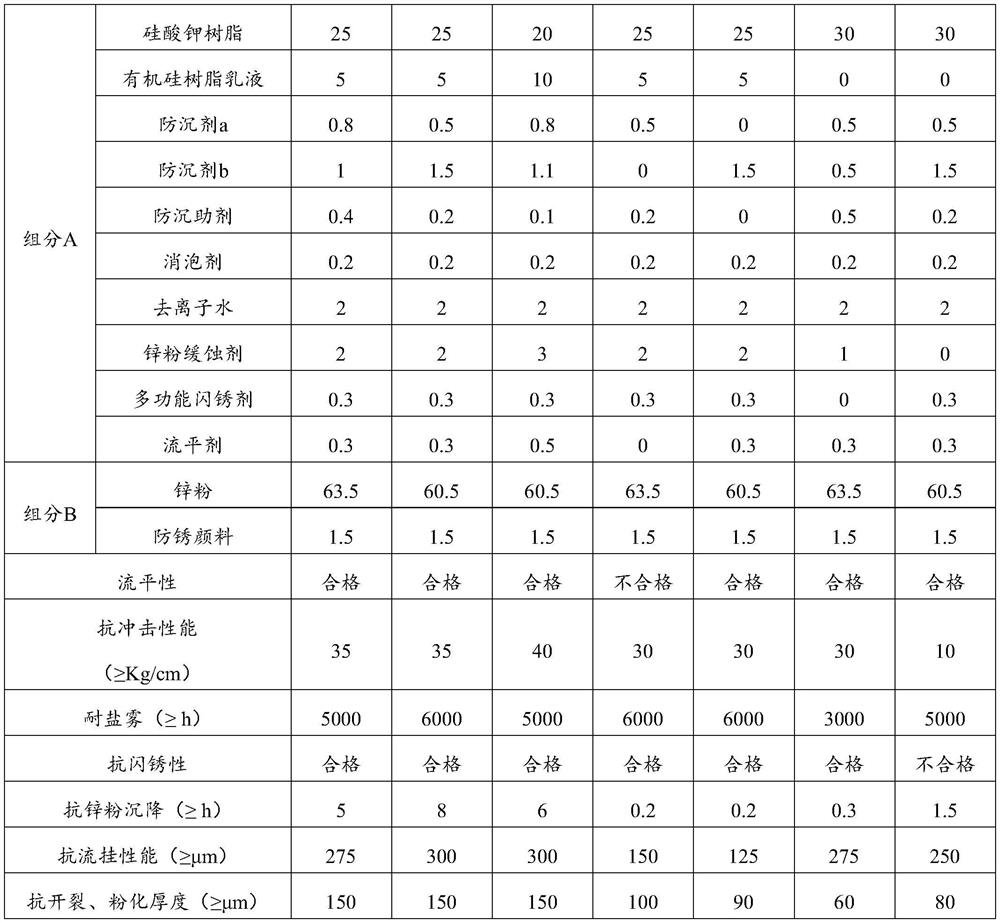

[0027] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below with reference to specific embodiments. Those skilled in the art should understand that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0028] The test methods used in the examples are conventional methods unless otherwise specified; the materials, reagents, etc. used can be obtained from commercial sources unless otherwise specified.

[0029] The raw materials used in the following examples and comparative examples are described below, but are not limited to these materials:

[0030] Potassium silicate resin: Hubei Bast E777-1, modulus>5.0M, pH value>11, density 1.0-1.5g / ml, viscosity (refer to "GB / T1723-93 Coating Viscosity Determination Method", testing conditions : 25℃, coating-4 cups) less than 20S;

[0031] Silicone resin em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com