Preparation method of high-temperature leveling agent for polyester dyeing

A technology of high-temperature leveling agent and polyester, which is applied in the field of polyester dyeing leveling agent, can solve the problems of good dispersion and insufficient dye migration, and achieve the effect of simple preparation process steps, avoiding the problem of color flower, and improving dye migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

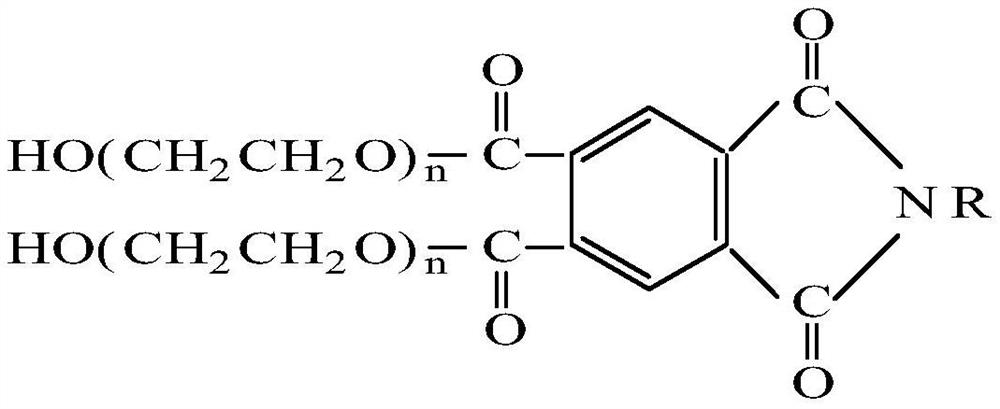

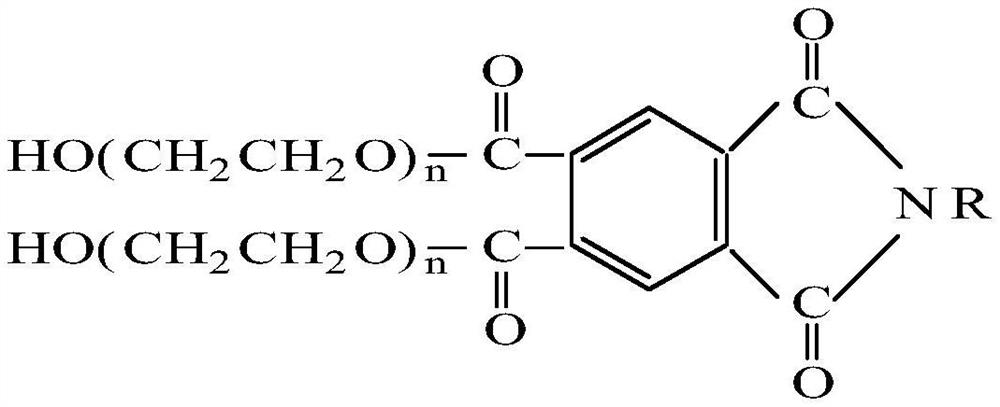

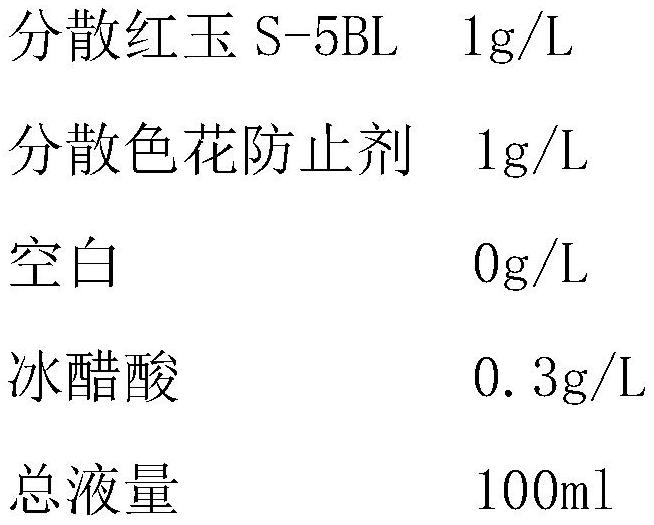

[0029] (1) Add pyromellitic dianhydride to n-butylamine and part of polyethylene glycol 400, keep the temperature at 70°C for 4h to carry out ring-opening amidation and esterification; under nitrogen atmosphere, heat up to 130°C , under the condition of vacuum degree -0.1MPa, dehydration ring-closure reaction is carried out for 6h to obtain N-n-butyl-4-carboxy-5-polyethylene glycol ester-phthalimide; among them, pyromellitic acid The molar ratio of dianhydride to n-butylamine is 1:1.05; the molar ratio of pyromellitic dianhydride to polyethylene glycol 400 is 1:1.05;

[0030] (2) N-n-butyl-4-carboxy-5-polyethylene glycol ester group-phthalimide obtained in step (1) and remaining polyethylene glycol 400 are used in catalyst methanesulfonic acid Under the nitrogen atmosphere, the temperature was raised to 140 ° C, and the dehydration esterification reaction was carried out under the condition of vacuum degree -0.1 MPa for 7 h to obtain N-n-butyl-4,5-dipolyethylene glycol ester-p...

Embodiment 2

[0032] (1) Add pyromellitic dianhydride to n-pentylamine and part of polyethylene glycol 600, keep at 80°C for 3h to carry out ring-opening amidation and esterification; under nitrogen atmosphere, heat up to 140°C , under the condition of vacuum degree -0.09MPa, dehydration and ring-closure reaction were carried out for 5h to obtain N-n-pentyl-4-carboxy-5-polyethylene glycol ester-phthalimide; among them, pyromellitic acid The molar ratio of dianhydride to n-amylamine is 1:1.1; the molar ratio of pyromellitic dianhydride to polyethylene glycol 600 is in the range of 1:1.1;

[0033] (2) N-n-pentyl-4-carboxy-5-polyethylene glycol ester group-phthalimide obtained in step (1) and residual polyethylene glycol 600 are reacted with catalyst methanesulfonic acid Under the nitrogen atmosphere, the temperature was raised to 150 ° C, and the dehydration esterification reaction was carried out under the condition of vacuum degree -0.09 MPa for 6 h to obtain N-n-pentyl-4,5-dipolyethylene g...

Embodiment 3

[0035] (1) Add pyromellitic dianhydride to n-hexylamine and part of polyethylene glycol 800, keep the temperature at 90°C for 2h to carry out ring-opening amidation and esterification; under nitrogen atmosphere, heat up to 150°C, Under the condition of vacuum degree -0.08MPa, dehydration and ring closure reaction was carried out for 4h to obtain N-n-hexyl-4-carboxy-5-polyethylene glycol ester-phthalimide; among them, pyromellitic dianhydride The molar ratio to n-hexylamine is 1:1.15; the molar ratio range of pyromellitic dianhydride to polyethylene glycol 800 is 1:1.15;

[0036] (2) N-n-hexyl-4-carboxy-5-polyethylene glycol ester base-phthalimide obtained in step (1) and remaining polyethylene glycol 800 under the effect of catalyst methanesulfonic acid , in a nitrogen atmosphere, the temperature was raised to 160 ℃, and the dehydration esterification reaction was carried out under the condition of vacuum degree -0.08MPa for 5h to obtain N-n-hexyl-4,5-dipolyethylene glycol est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com