Inclined shaft tunnel full-section mechanical tunneling device and construction method

A full-section, mechanical technology, applied in tunnels, shaft equipment, earthwork drilling and mining, etc., can solve the problems that cannot meet the needs of inclined shaft tunnel excavation, and achieve high-precision one-time penetration construction, small deviation correction error, and convenient slag discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

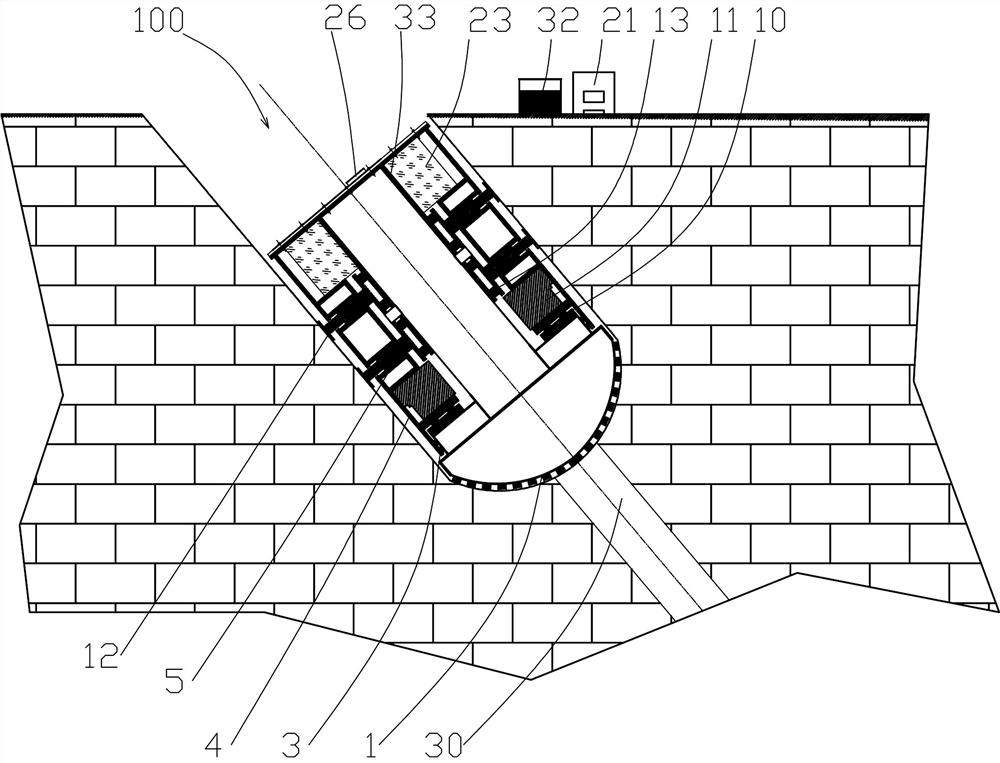

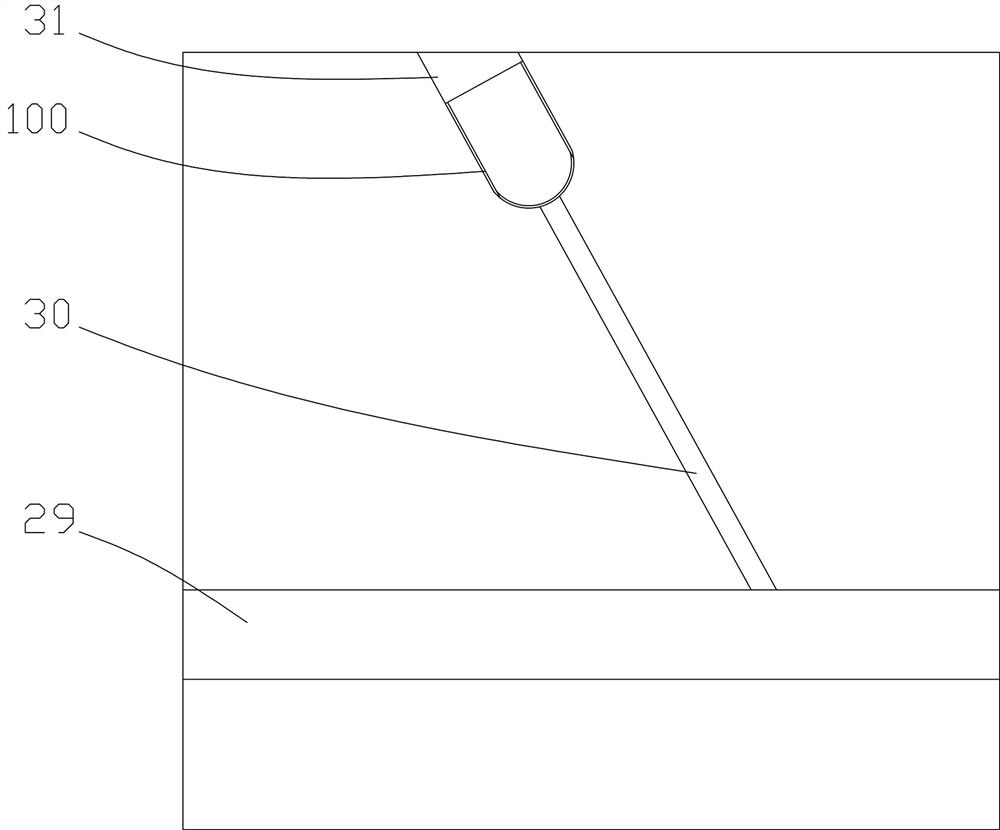

[0025] An inner support 5 is arranged in the support ring 4 , and a feeding oil cylinder 11 is arranged between the inner support 5 and the drill bit 1 , and the feeding oil cylinder 11 is used to push the drill bit 1 for feeding. With this structure, while the full-section mechanical excavation device 100 is excavating, the driving inclination of the full-section mechanical excavation device 100 can also be adjusted online according to the design angle of the inclined shaft tunnel 31 .

[0026] The preferred solution is figure 1 Among them, a seal 3 is provided between the support ring 4 and the drill bit 1, and the outer diameter of the drill bit 1 is larger than that of the support ring 4; this structure prevents drilling slag from entering the support ring 4 and affects the work of the movable parts.

[0027] The hydraulic motor 23 and the transmission sleeve 33 are connected in a relatively sliding manner that can transmit torque. For example, they are connected in a spl...

Embodiment 2

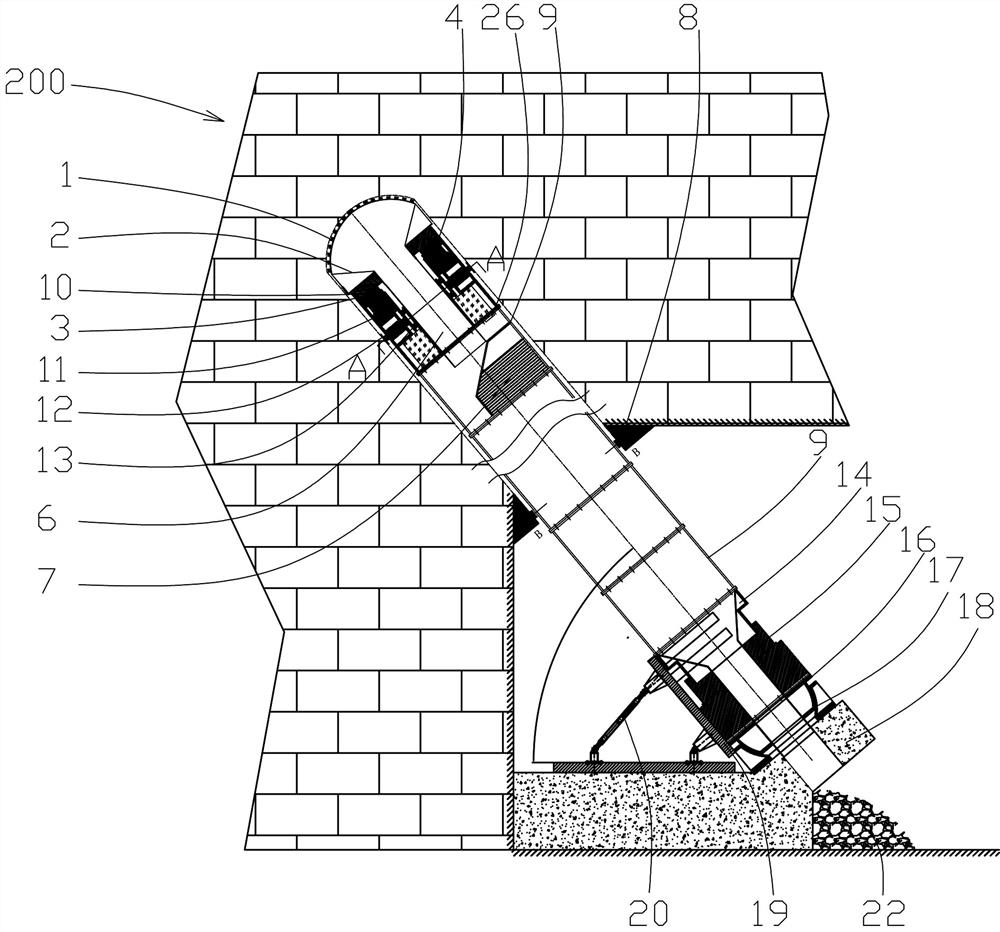

[0036] The support ring 4 is connected with the drill bit system, and the support ring 4 includes a jacking section steel pipe 9 that can be increased or decreased to adjust the length of the support ring 4; the jacking section steel pipe 9 and the support ring 4 are connected by flanges and bolts. The outer diameter of the drill bit 1 is larger than the outer diameter of the support ring 4 . Preferably, the outer diameter of the drill bit 1 is larger than the outer diameter of the connecting flange of the support ring 4 by about 2 cm. The jacking cylinder 15 is used to jack the support ring 4 and transmit the jacking force to the drill bit system. Further preferred solutions such as image 3 , 8 , the structure of the drill bit system is as follows: the drill bit 1 and the support ring 4 are slidingly and sealedly connected, and a seal 3 is provided at the connection position to prevent drill cuttings from entering the support ring 4, and the tail of the drill bit 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com