Multi-medium coupling variable-temperature pressure corrosion test device and test method

A test device and multi-media technology, applied in the field of multi-media coupling variable temperature pressure dissolution test device, can solve problems such as temperature fluctuation of pressure water, and achieve the effects of accurate evaluation, strong operability and clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

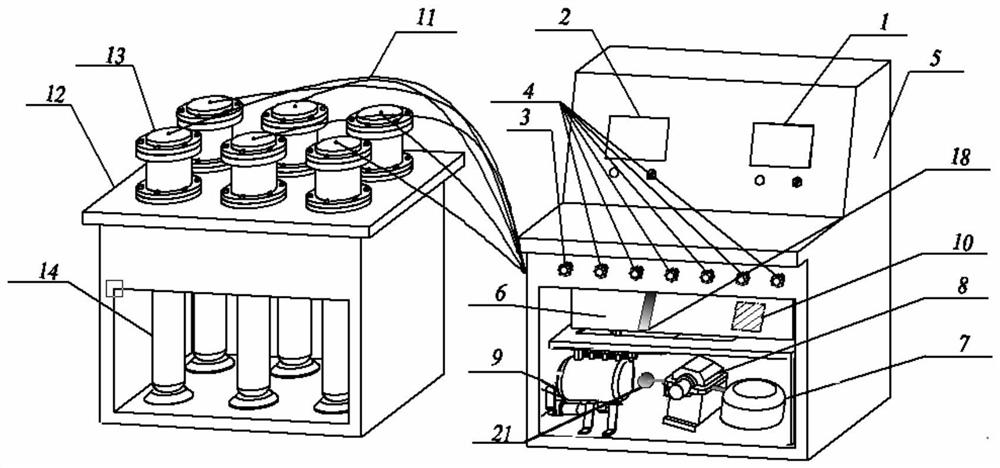

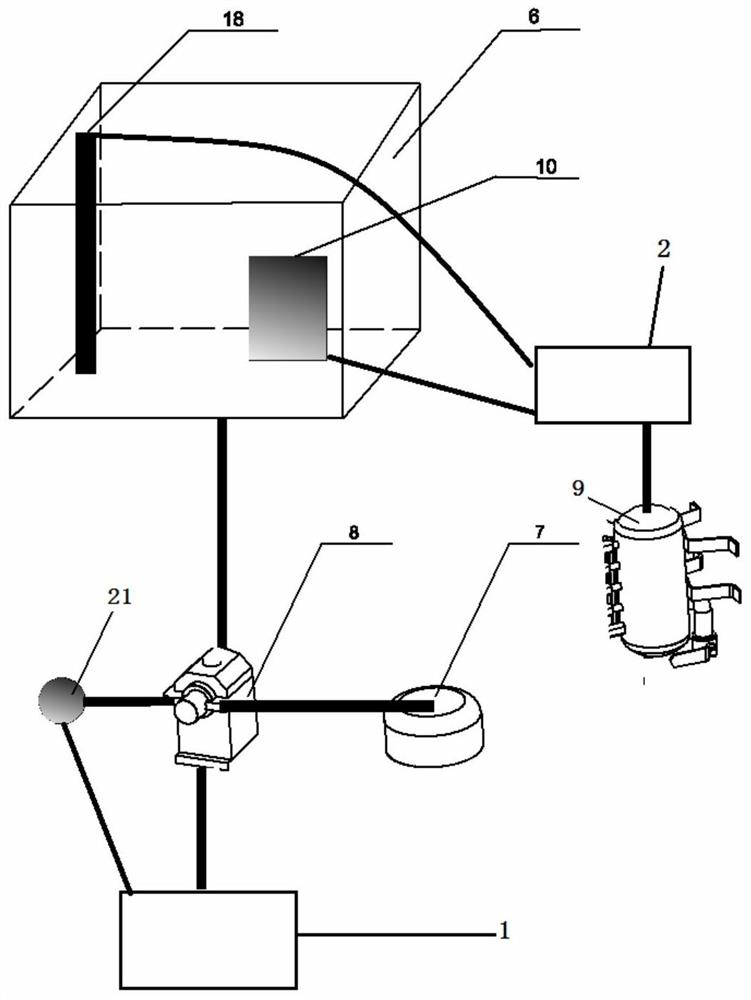

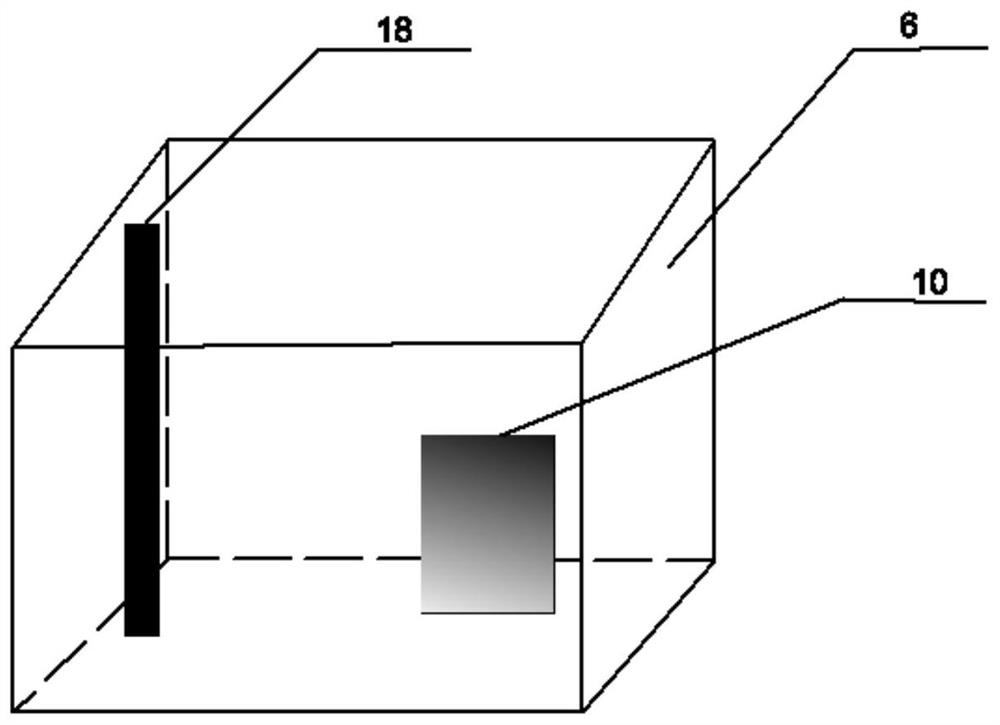

[0068] A multi-medium coupling variable temperature pressure corrosion test device, which includes the following components:

[0069] Including pressure control system, temperature control system, pressure supply valve, pressure relief valve, medium tank, drive motor, pressure pump, condenser, connecting pipe, sample cylinder, graduated cylinder, frame I and frame II;

[0070] Pressure control system: the pressure control range is 0~8MPa, and the accuracy is ±0.2%;

[0071] Temperature control system: the temperature control range is 5 to 80°C, and the accuracy is ±1°C;

[0072] The medium box, sample cylinder and connecting pipe are made of 316 stainless steel, which can hold various acid, alkali and salt solutions;

[0073] The size of the sample tube is ф150mm*150mm, and the accuracy is ±4mm, with a total of 6 pieces.

[0074] The corrosion resistance test and evaluation of the concrete specimens of a certain project are carried out, and they are sealed with paraffin wax....

Embodiment 2

[0077] A multi-medium coupling variable temperature pressure corrosion test device, which includes the following components:

[0078] Including pressure control system, temperature control system, pressure supply valve, pressure relief valve, medium tank, drive motor, pressure pump, condenser, connecting pipe, sample cylinder, graduated cylinder, frame I and frame II;

[0079] Pressure control system: the pressure control range is 0~10MPa, and the accuracy is ±0.2%;

[0080] Temperature control system: the temperature control range is -5 to 100°C, and the accuracy is ±1°C;

[0081] The medium box, sample cylinder and connecting pipe are made of 304 stainless steel, which can hold most acid, alkali and salt solutions;

[0082] The size of the sample tube is ф100mm*100mm, and the accuracy is ±4mm, with a total of 6 pieces.

[0083] The corrosion resistance test and evaluation of the concrete specimens of a certain project are carried out, and the asphalt is sealed. The sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com