Nickel foil for manufacturing thin film capacitor and manufacturing method thereof

A technology of nickel foil and dielectric, which is applied in the field of electrolytic nickel foil, can solve the problems that are not enough to manufacture thin-film ceramic film capacitors, and achieve the effect of excellent processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of Electrolytic Nickel Foil

[0044] The electrolytic nickel foil may be prepared by electrolytic plating with an electrolytic solution containing a nickel ion precursor, a pH buffer, and a roughness control agent and having a pH of 1 to 5.

[0045] The content of the nickel ion precursor of the electrolytic solution is about 400 g / L to 600 g / L relative to the total volume of the electrolytic solution, and within the above ranges, the electrolytic nickel foil is excellent in surface roughness and gloss. The nickel ion precursor can be used without limitation as long as it is a precursor used in nickel ion plating, and the nickel ion precursor is preferably selected from the group consisting of nickel sulfate, nickel sulfamate, nickel chloride, and nickel nitrate group. More preferably, nickel sulfate or nickel sulfamate is used.

[0046] The roughness control agent may comprise selected from the group consisting of saccharin, carboxyethyl isothiourea chl...

Embodiment 1

[0073] An electrolyte containing about 450 g / L of nickel sulfate as a nickel ion precursor, about 25 g / L of boric acid as a pH buffer, and about 0.1 g as a roughness control agent was used with an electrolyte containing the following substances at a pH of about 3 / L of saccharin and about 0.8g / L of sodium allyl sulfonate, and at an electrolyte temperature of about 55°C, at about 20A / dm 2 A current density of about 400 s was applied to prepare a nickel foil with a thickness of about 27 μm.

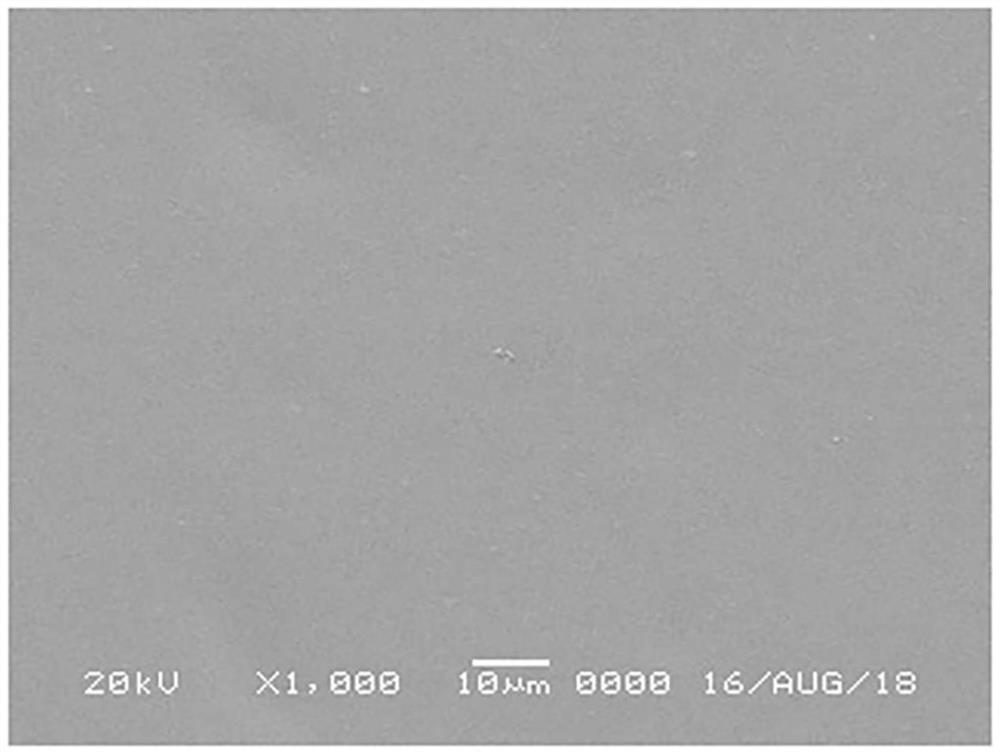

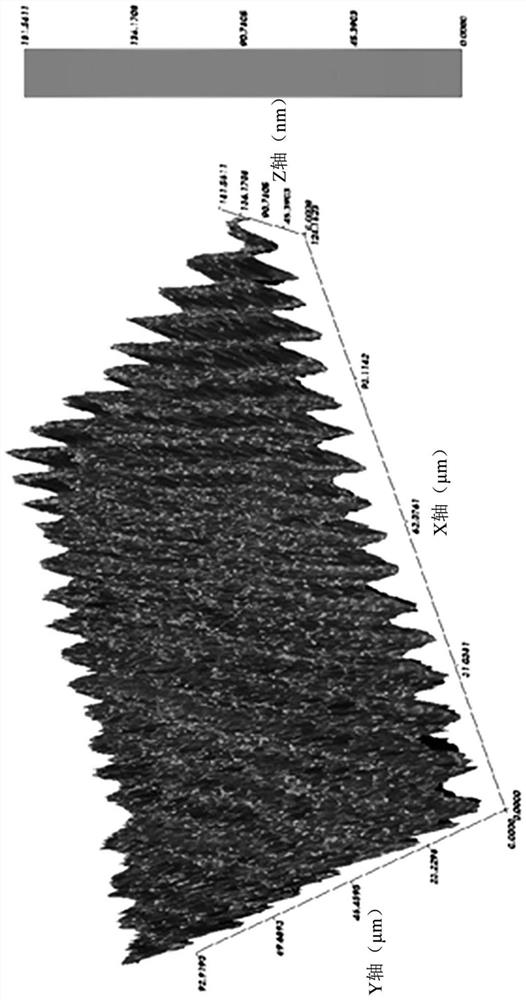

[0074] In the unpolished state, the surface of the prepared electrolytic nickel foil had an arithmetic mean roughness (Ra) of about 0.05 μm, a ten-point mean roughness (Rz) of about 0.19 μm, and a maximum raised height (Rt) of about 0.37 μm, and the 60° specular gloss is about 445GU.

Embodiment 2 to 10

[0076] An electrolytic nickel foil was prepared in the same manner as in Example 1, except that the electrolytic solution and electrolytic conditions shown in Table 1 below were applied.

[0077] [Table 1]

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com