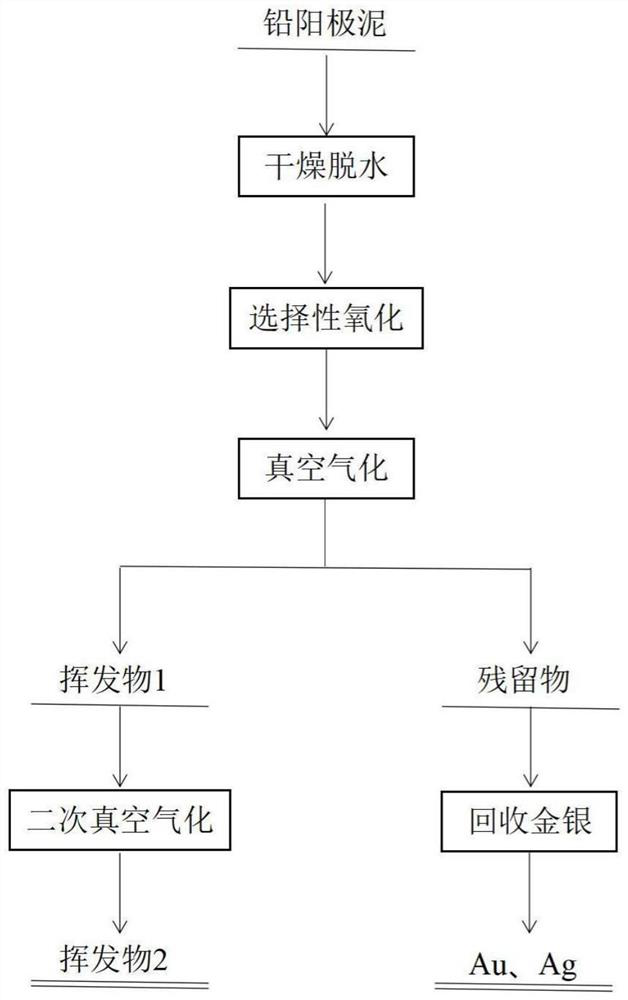

Method for efficiently separating arsenic from lead anode slime through low-pressure oxidation

A lead anode slime and low pressure technology is applied in the field of high-efficiency separation of arsenic by low-pressure oxidation of lead anode slime. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

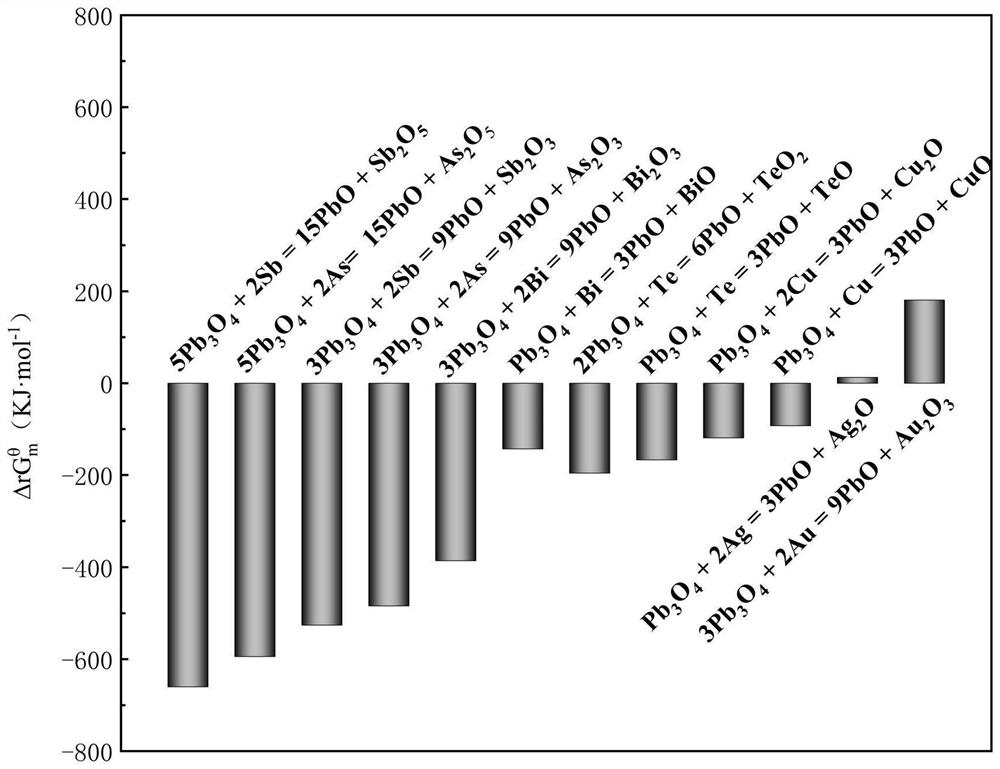

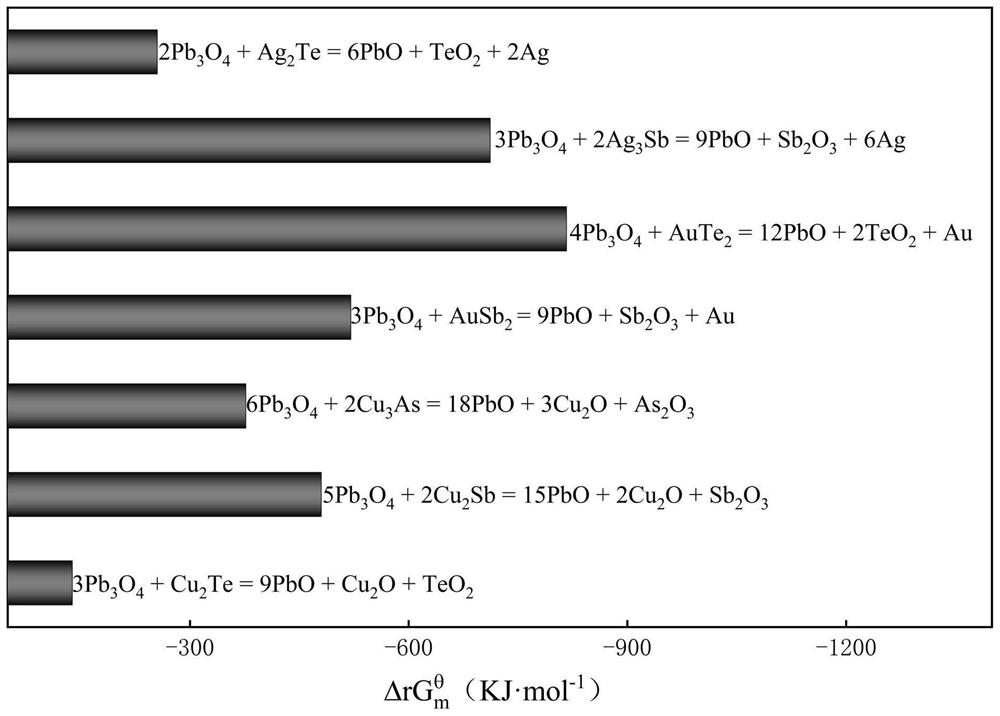

Method used

Image

Examples

Embodiment 1

[0026] Take 200g of lead anode slime and put it in a drying box and dry it at 120°C for 4 hours; take 50g of dried lead anode slime, add oxidant Pb 3 O 4 Grind together and put them into the crucible evenly, and put the crucible into the vertical resistance furnace; extract the air in the furnace until the pressure is stable at 10Pa, heat up to 698K, and keep the temperature for 3h. After the low-pressure gasification is completed, the first volatiles are collected at the condensing end and weighed for chemical analysis. The removal rate of arsenic was 96.84%.

[0027] Please refer to figure 2 and Figure 5 , grind the first volatile matter into a crucible, put it into a vertical resistance furnace, draw out the air in the furnace until the pressure is stable at 10Pa, heat up to 1173K, and keep the temperature for 4h. After the low-pressure gasification is completed, the second volatiles are collected at the condensing end and weighed for chemical analysis. The removal r...

Embodiment 2

[0050] Take 50g of dried lead anode slime, add oxidant Pb 3 O 4 Grind together and put them into the crucible evenly, and put the crucible into the vertical resistance furnace; extract the air in the furnace until the pressure is stable at 20Pa, heat up to 823K, and keep the temperature for 3h. After the low-pressure gasification is completed, the first volatiles are collected at the condensing end and weighed for chemical analysis. The removal rate of arsenic was 96.72%.

[0051] Grind the first volatile matter and put it into a crucible, put it into a vertical resistance furnace, extract the air in the furnace until the pressure is stable at 20Pa, heat up to 1173K, and keep the temperature for 4h. After the low-pressure gasification is completed, the second volatiles are collected at the condensing end and weighed for chemical analysis. The removal rate of arsenic was 98.77%, and the direct yields of gold and silver obtained in the residual area were 96.21% and 97.83%, re...

Embodiment 3

[0053] Take 50g of dried lead anode slime, add oxidant Pb 3 O 4 Grind together and put them into the crucible evenly, put the crucible into the vertical resistance furnace; extract the air in the furnace until the pressure is stable at 10Pa, heat up to 798K, and keep the temperature for 3h. After the low-pressure gasification is completed, the first volatiles are collected at the condensing end and weighed for chemical analysis. The removal rate of arsenic was 96.91%.

[0054] Grind the first volatile matter and put it into a crucible, put it into a vertical resistance furnace, draw out the air in the furnace until the pressure is stable at 10Pa, heat up to 1273K, and keep the temperature for 4h. After the low-pressure gasification is completed, the second volatiles are collected at the condensing end and weighed for chemical analysis. The removal rate of arsenic was 99.11%, and the direct yields of gold and silver obtained in the residual area were 97.77% and 98.52%, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com