Plug board curtain wall structure and construction method

A plug-in board and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of deviation adaptability of the installation main structure, difficulty in splicing adjacent units, waste of skeleton materials, etc., and save material costs. and labor costs, sufficient adjustability, and the effect of fewer manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

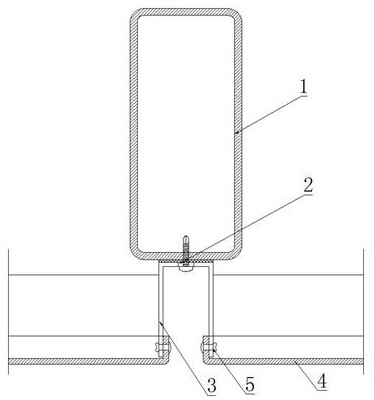

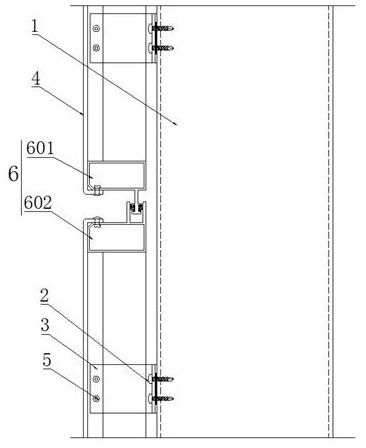

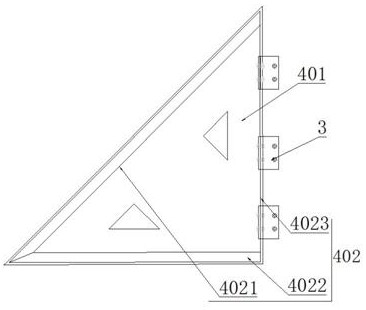

[0038] In order to make the technical solutions and beneficial effects of the present application clearer, the following is combined with the appendix Figure 1-10 This application will be described in further detail.

[0039] A plug-in board curtain wall structure, comprising:

[0040] The main frame 1, the main frame 1 is arranged in the longitudinal direction;

[0041] For the unit frame 4, the longitudinal side of each unit frame 4 is connected with the longitudinal side of the main frame 1, and the upper and lower sides of each unit frame 4 are connected with the adjacent unit frame 4 by movable plugboards.

[0042] like Figure 1-2 As shown, it is a schematic diagram of the cross section and vertical section of the curtain wall. In order to ensure the stability of the support, the main frame 1 adopts the square tube steel columns arranged in the longitudinal direction. The corrosion resistance of atmospheric pollution also has a certain protective effect on corrosion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com