Heat treatment device

A heat treatment device and heat treatment technology are applied in vacuum evaporation plating, coating, gaseous chemical plating and other directions, which can solve problems such as danger and achieve the effect of reducing installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

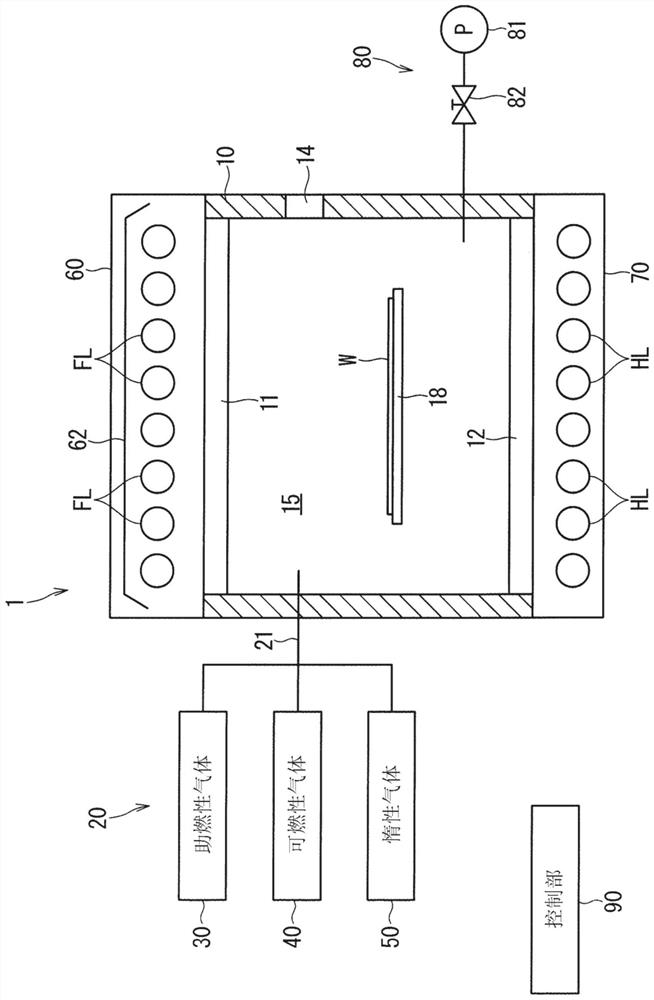

[0031] figure 1 It is a figure which shows the structure of the main part of the heat processing apparatus 1 of this invention. figure 1 The heat treatment apparatus 1 is a flash lamp annealing apparatus, and heats the semiconductor wafer W by irradiating a flash light to the semiconductor wafer W in the shape of a disk as a substrate. The size of the semiconductor wafer W to be processed is not particularly limited, but is, for example, φ300 mm or φ450 mm. also, figure 1 In the drawings and the following figures, the size or number of each part is exaggerated or simplified as necessary for easy understanding.

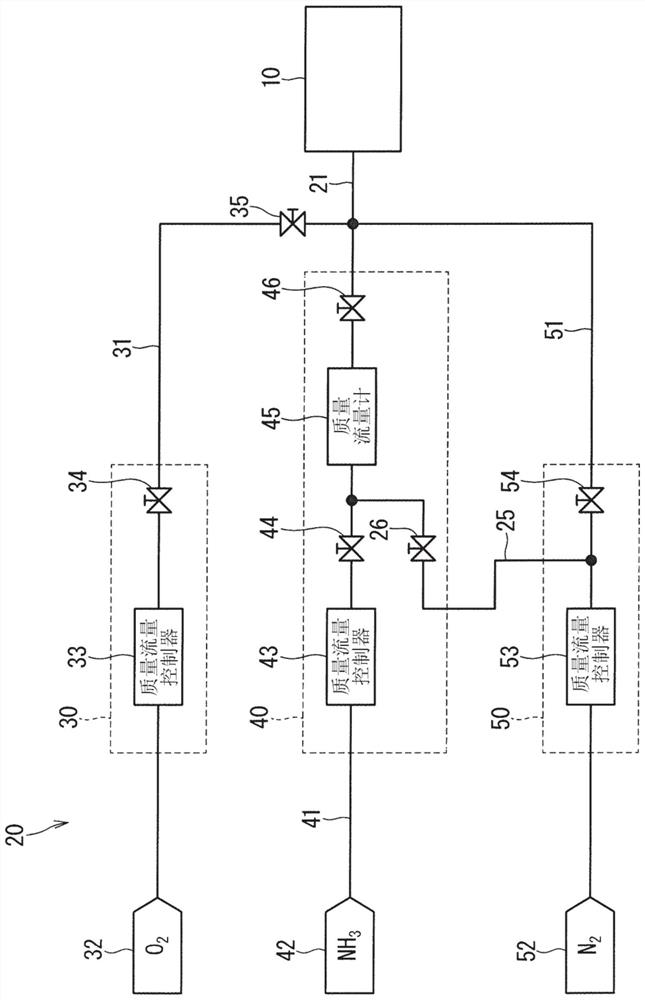

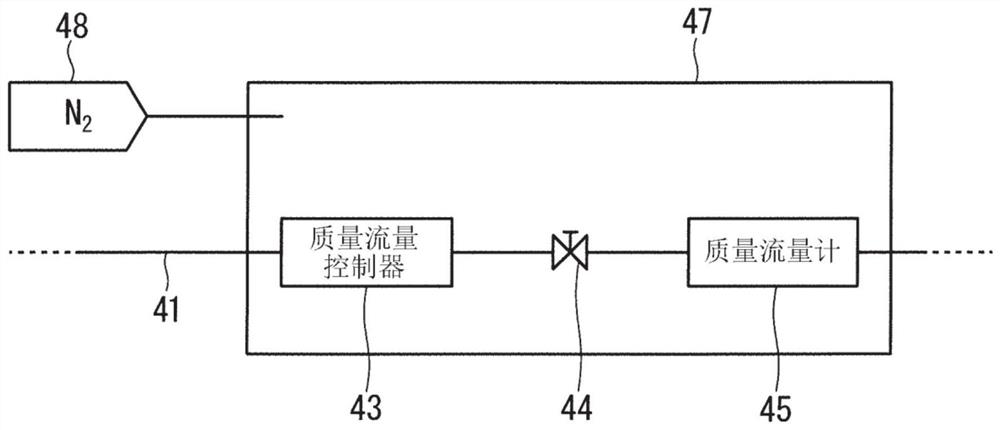

[0032] The heat treatment apparatus 1 includes: a chamber 10 that houses the semiconductor wafers W; a flash irradiation unit 60 that irradiates a flash light to the semiconductor wafers W in the chamber 10 ; a halogen irradiation unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com