Positive electrode active material for lithium secondary battery and lithium secondary battery comprising same

A positive electrode active material, lithium secondary battery technology, applied in the direction of active material electrodes, battery electrodes, positive electrodes, etc., can solve the problems of particle surface damage, difficult to achieve capacity and life of lithium secondary batteries, uneven chemical structure, etc. Achieve the effect of improving the initial capacity and improving the battery efficiency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

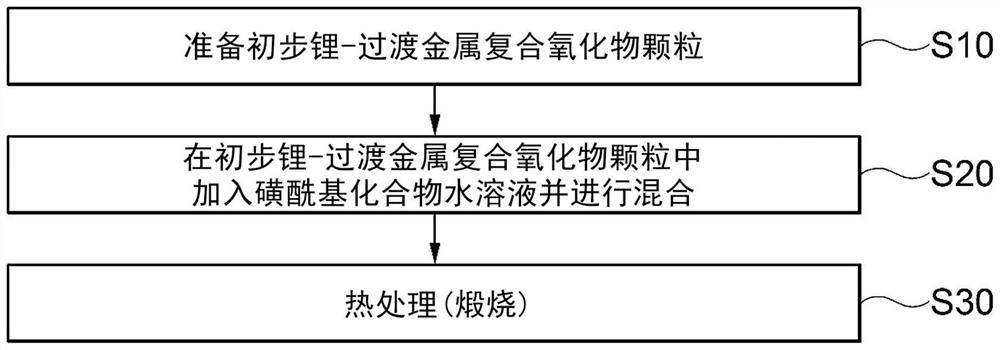

[0098] figure 1 is a process flow diagram for illustrating a method of preparing a positive electrode active material of an exemplary embodiment.

[0099] Below, refer to figure 1 , a preparation method according to an exemplary embodiment of the above-described positive electrode active material for a lithium secondary battery is provided.

[0100] refer to figure 1 , preliminary lithium-transition metal composite oxide particles may be prepared (eg, step S10 ).

[0101] For example, by reacting a transition metal precursor with a lithium precursor, preliminary lithium-transition metal composite oxide particles can be prepared. The transition metal precursor (eg, Ni-Co-Mn precursor) can be prepared by a coprecipitation reaction.

[0102] For example, transition metal precursors can be prepared by coprecipitation of metal salts. The metal salts may include nickel salts, manganese salts and cobalt salts.

[0103] Examples of the nickel salt include nickel sulfate, nickel ...

Embodiment 1

[0152] Preparation of Preliminary Lithium-Transition Metal Composite Oxide Particles (S10)

[0153] use N 2Distilled water that was bubbled for 24 hours to remove internal dissolved oxygen was mixed with NiSO at a ratio of 0.885:0.090:0.025, respectively 4 , CoSO 4 , MnSO 4 . Add the above solution to the reactor at 50°C using NaOH and NH 3 H 2 O was used as a precipitant and a chelating agent, and a co-precipitation reaction was carried out for 48 hours, thereby obtaining Ni as a transition metal precursor 0.885 Co 0.09 Mn 0.025 (OH) 2 . The precursor obtained was dried at 80°C for 12 hours and then at 110°C for a further 12 hours.

[0154] Lithium hydroxide and the transition metal precursor were added to a dry high-speed mixer at a ratio of 1.01:1 and mixed uniformly for 5 minutes. The mixture was placed in a calciner, heated to 730-750°C at a ramp rate of 2°C / min, and held at 730-750°C for 10 hours. During the ramp-up and hold, oxygen was continuously passed ...

Embodiment 2

[0166] A positive electrode active material and a lithium secondary battery were obtained by the same method as in Example 1, except that 0.8% by weight of ammonium sulfate powder with respect to the total weight of the preliminary lithium-transition metal composite oxide particles was added to pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com