Thickening method and thickening formula of fatty alcohol polyoxyethylene ether sodium sulfate

A technology of alcohol polyoxyethylene ether sodium sulfate and fatty acid diethanolamide, which is applied in the direction of pharmaceutical formulations, chemical instruments and methods, medical preparations containing active ingredients, etc., can solve the problem of high cost of single thickener and limited production equipment Corrosiveness, reducing the service life of equipment, etc., to achieve the effect of antibacterial and anti-mildew investment cost, no corrosion of production equipment, and increased friction

Pending Publication Date: 2022-06-10

辽宁华星日化产业技术研究院有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current thickening method of AES has the high cost of using a single thickener, and the Cl produced by ionization of inorganic salts - , SO 4 2- It is corrosive to the production equipment and reduces the service life of the equipment. At the same time, the high content of inorganic salts is highly irritating to the skin, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

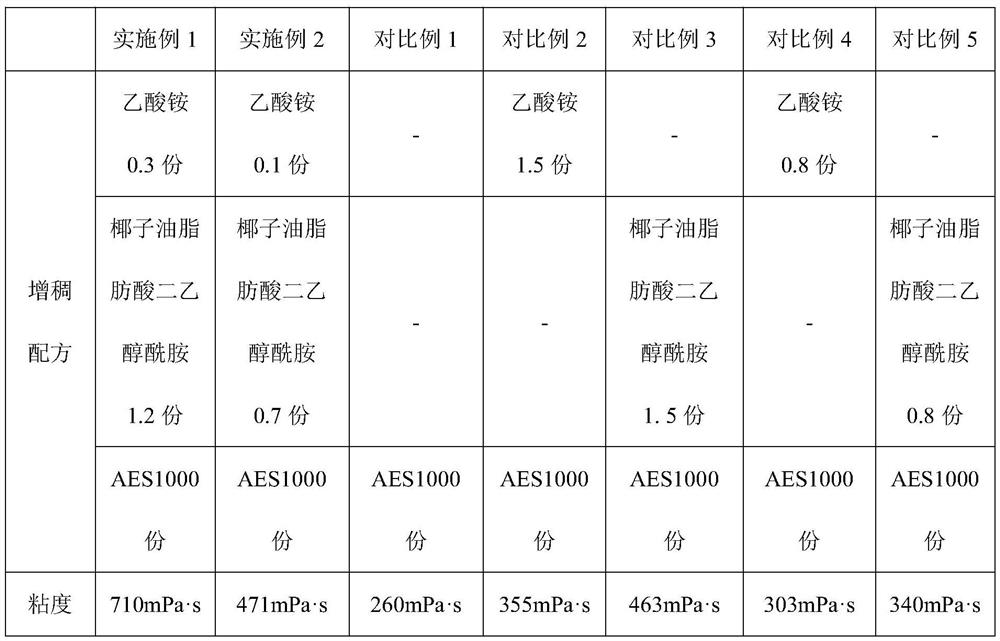

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a fatty alcohol polyoxyethylene ether sodium sulfate thickening method, which specifically comprises: 1, pre-preparing: adding ammonium acetate and cocoanut fatty acid diethanolamide to 40 parts of AES, heating to 40-50 DEG C, and stirring until complete dissolution to prepare a mixture; and step 2, adding the mixture pre-prepared in the step 1 into 960 parts of AES in batches, heating to 40-50 DEG C, and stirring until the mixture is uniformly stirred. The invention also discloses a thickening formula of fatty alcohol polyoxyethylene ether sodium sulfate. The thickening formula comprises the following components in parts by weight: 0.1-0.3 part of ammonium acetate, 0.7-1.2 parts of cocoanut fatty acid diethanolamide and 1000 parts of AES. Ammonium acetate is added into AES and is compounded with cocoanut fatty acid diethanolamide to increase viscosity, so that a relatively good thickening effect is achieved. The process is simple, industrial production is easy, the addition amount is small, the AES thickening effect is better, production equipment is not corroded, irritation to skin is avoided, the antibacterial and mildew-proof functions are achieved, and the input cost is low.

Description

A kind of thickening method and thickening formula of fatty alcohol polyoxyethylene ether sodium sulfate technical field The present invention relates to fatty alcohol polyoxyethylene ether sodium sulfate preparation technical field, particularly a kind of fatty alcohol polyoxyethylene Thickening method and thickening formula of sodium alkenyl ether sulfate. Background technique Fatty alcohol polyoxyethylene ether sodium sulfate (AES) is widely used in shampoo, bath liquid, dishwashing detergent, compound soap etc. Polyester cosmetic products, thickening AES can reduce its dosage and save costs for enterprises. At present, thickeners or non- Organic salts thicken AES. Li Yinghua and others studied the thickening of AES by sodium chloride, potassium chloride, ammonium chloride and ammonium sulfate, and concluded that When the AES concentration is less than 5%, the thickening effect of sodium chloride is the best, but the addition amount is also large (about 7-8%); Ji...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D1/83C11D3/20C11D3/48A61K8/36A61K8/42A61K8/46A61Q19/10

CPCC11D1/83C11D3/2079C11D3/48A61K8/463A61K8/42A61K8/36A61Q19/10C11D1/29C11D1/66A61K2800/48

Inventor 赵娇娇何延胜尹文婷李巧云张金柱

Owner 辽宁华星日化产业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com