Vesicle type MOF/GO composite material and preparation method thereof

A technology of composite materials and vesicles, applied in the field of composite materials, can solve the problems of uneven dispersion of MOF, affecting the performance of MOF-GO composite materials, poor stability, etc., to achieve uniform distribution, high recombination rate, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

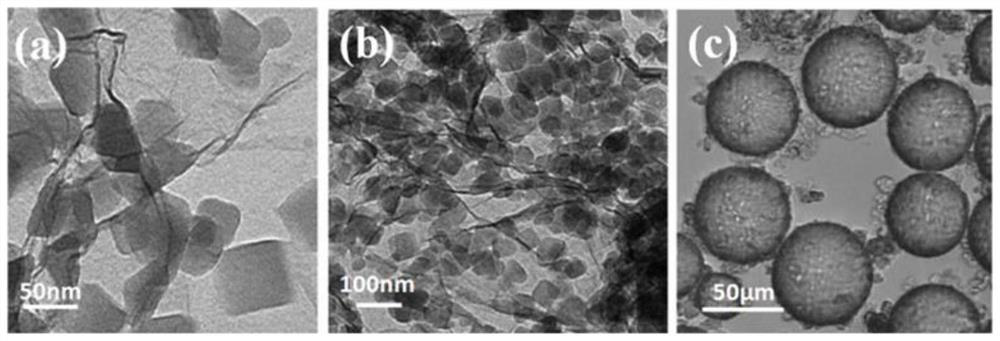

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a vesicle-type MOF / GO composite material, comprising the following steps:

[0033] Step 1, using Hummers method to carry out oxidation peeling treatment on graphite to obtain graphene oxide;

[0034] Step 2, dispersing the prepared graphene oxide in an aqueous solution and ultrasonically dispersing for 1-1.5 h to obtain a graphene oxide dispersion; the concentration of the graphene oxide dispersion is 2-3 mg / mL;

[0035] Step 3, prepare oil phase solution and water phase solution; wherein, oil phase solution is prepared by dissolving organic ligands in water-insoluble organic solvent; water phase solution includes deionized aqueous solution dissolved with metal salt and prepared in step 2 The obtained graphene oxide dispersion; the concentration of the oil phase solution is 10~15mg / mL; in the deionized aqueous solution dissolved with the metal salt, the concentration of the metal salt is 5~8mg / mL; the organic ligand is pref...

Embodiment 1

[0042] The preparation method of the vesicle-type MOF / GO composite material of this embodiment 1 includes the following steps:

[0043] Step 1, using Hummers method to carry out oxidation peeling treatment on graphite to obtain graphene oxide;

[0044] Step 2, dispersing the prepared graphene oxide in an aqueous solution and ultrasonically dispersing for 1 h to obtain a graphene oxide dispersion liquid with a concentration of 2 mg / mL;

[0045]Step 3, prepare an oil phase solution and an aqueous phase solution; wherein, the oil phase solution is an octanol solution (5 mL) dissolved with 68.7 mg of methylimidazole; the aqueous phase solution includes dissolved ZnSO 4 .7H 2 O (32.3 mg) in deionized water (5 mL) and graphene oxide dispersion (5 mL).

[0046] Step 4: Mix the above-mentioned oil phase solution and aqueous phase solution, and use a high-shear emulsifier B25 to emulsify the mixed solution at a rotational speed of 10,000 rpm for 5 minutes to obtain an emulsion; heat ...

Embodiment 2

[0053] The preparation method of the vesicle-type MOF / GO composite material of this embodiment 2 includes the following steps:

[0054] Step 1, using Hummers method to carry out oxidation peeling treatment on graphite to obtain graphene oxide;

[0055] Step 2, dispersing the prepared graphene oxide in an aqueous solution and ultrasonically dispersing for 1 h to obtain a graphene oxide dispersion liquid with a concentration of 2 mg / mL;

[0056] Step 3, prepare oil phase solution and water phase solution; wherein, the oil phase solution is an octanol solution (5mL) dissolved with 75mg methylimidazole; the water phase solution includes a deionized aqueous solution (30mg) dissolved with zinc nitrate hexahydrate ( 5 mL) and graphene oxide dispersion (5 mL).

[0057] Step 4: Mix the above-mentioned oil phase solution and aqueous phase solution, and use a high-shear emulsifier B25 to emulsify the mixed solution at a rotational speed of 10,000 rpm for 5 minutes to obtain an emulsion;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com