Monolithic polytrifluorochloroethylene bipolar membrane containing metal phthalocyanine derivative water dissociation catalyst and preparation method of monolithic polytrifluorochloroethylene bipolar membrane

A technology of polychlorotrifluoroethylene and metal phthalocyanine, which is applied in chemical instruments and methods, ion exchange, anion exchange, etc., can solve the problems of reducing the service life of bipolar membranes and easy peeling, and achieves low transmembrane voltage and low transmembrane voltage. The effect of drain and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

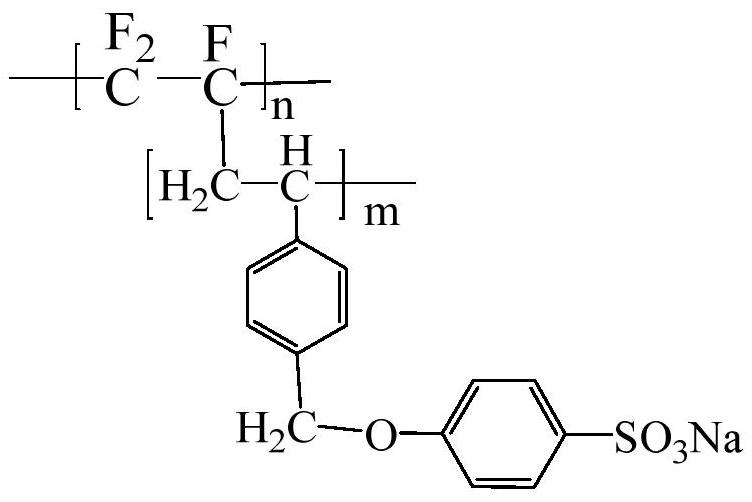

[0037] A monolithic polychlorotrifluoroethylene bipolar membrane containing a metal phthalocyanine derivative hydrolysis catalyst, wherein a sulfonic acid group is introduced into one side of the bipolar membrane, and a quaternary ammonium group is introduced into the other side; the cation exchange membrane in the bipolar membrane The structural formula is:

[0038]

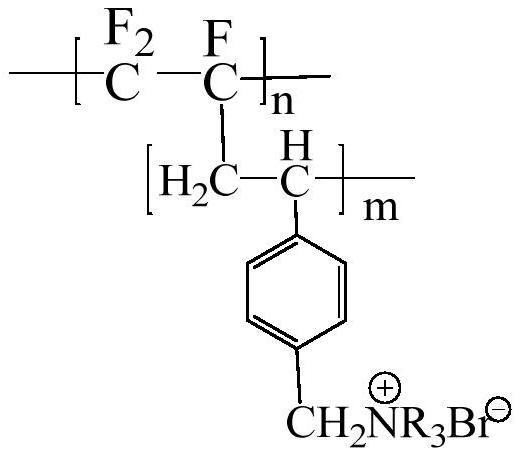

[0039] The structural formula of the anion exchange membrane is:

[0040]

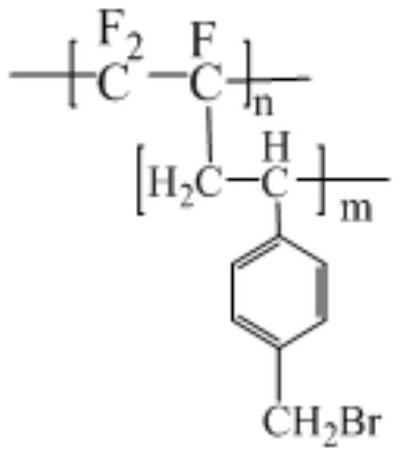

[0041] The structural formula of the catalyst between the intermediate interfaces is:

[0042]

[0043] Wherein, n is the degree of polymerization of the main chain of the polytrifluorochloro-vinyl film, m is the degree of polymerization of the side chains of polybromomethylstyrene, and n and m are integers other than zero.

Embodiment 2

[0045]A monolithic polychlorotrifluoroethylene bipolar membrane containing a metal phthalocyanine derivative water dissociation catalyst, comprising the following steps:

[0046] S1. Preparation of polychlorotrifluoroethylene grafted polymethylstyrene copolymer (PCTFE-g-PMSt): weigh 20 g of polychlorotrifluoroethylene and dissolve it in 200 mL of N-methylpyrrolidone, pass nitrogen to remove oxygen, and heat up to After 110°C, 144.1g of 4-methylstyrene, 8.72g of CuBr and 9.52g of bipyridine were added to the reaction system. Under the protection of nitrogen, the reaction solution was poured into alcohol water with a volume ratio of 1:1 after constant temperature reaction for 40h. In the mixed solvent, the graft conjugate was obtained by precipitation; the precipitate was rinsed with alcohol water for several times and then soaked in running water for 24 hours to remove copper ions and bipyridine, filter and dry, and put the precipitate into a Soxhlet extractor Extracted with to...

Embodiment 3

[0055] A preparation method of a monolithic polychlorotrifluoroethylene bipolar membrane containing a metal phthalocyanine derivative water dissociation catalyst, comprising the following steps:

[0056] S1. Preparation of polychlorotrifluoroethylene grafted polymethylstyrene copolymer (PCTFE-g-PMSt): Weigh 20 g of polychlorotrifluoroethylene and dissolve it in 200 mL of dimethyl sulfoxide, pass nitrogen to remove oxygen, and heat up to 110 After ℃, 180.1g of 2-methylstyrene, 8.72g of CuBr and 21.13g of pentamethyldiethylenetriamine were added to the reaction system, and under nitrogen protection, the reaction solution was poured into a volume ratio of 1:1 after constant temperature reaction for 5h. In the mixed solvent of alcohol and water, the graft conjugate was precipitated; the precipitate was rinsed with alcohol water for several times and then soaked in running water for 24 hours to remove copper ions and pentamethyldiethylenetriamine, filtered and dried, and the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com