Talcum powder master batch with low breakage rate and high hardness as well as preparation method and application thereof

A technology of talc masterbatch and crushing rate, applied in the field of plastic additives, can solve the problems of unusability, cracking of masterbatch, reduction of masterbatch yield, etc., achieving good performance, improving talc powder bridging, and low crushing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

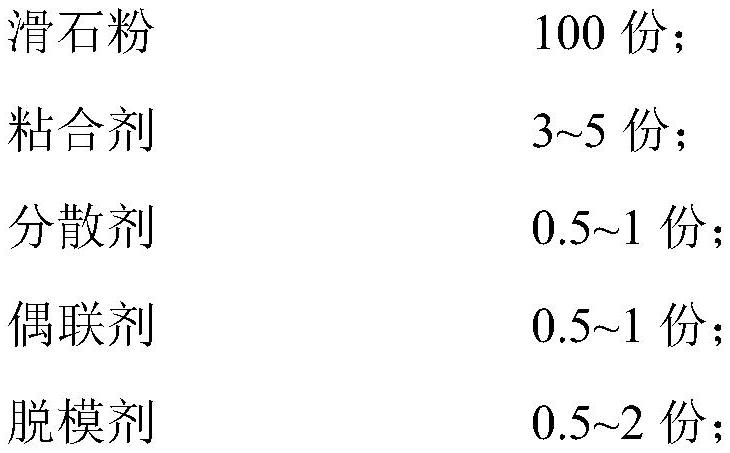

Method used

Image

Examples

Embodiment 27

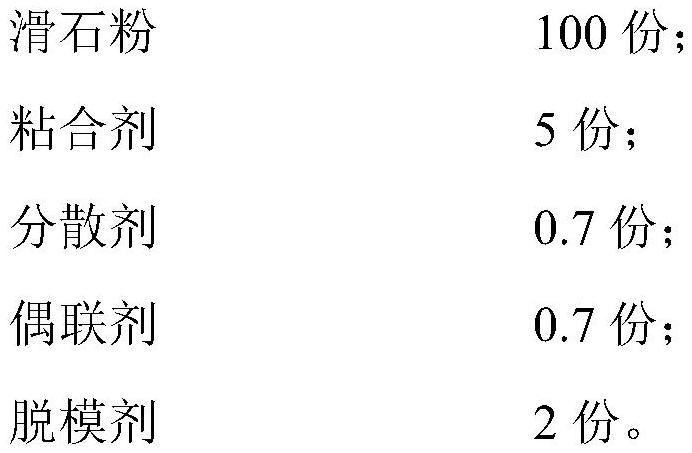

[0080] The present embodiment prepares a kind of talc master batch, which is prepared according to the following method:

[0081] According to the formula of Example 3, add talcum powder, binder, dispersant, coupling agent and mold release agent into the high-speed mixer, mix at 60°C for 100s at a frequency of 40Hz, and obtain a premix after mixing uniformly Then, the obtained premix is added to a twin-screw extruder, extruded at normal temperature (20-30° C.), and pelletized under water to obtain the talc masterbatch.

Embodiment 3

[0115] The results of Examples 3-6 show that: with the increase of the magnesium stearate content ratio in the dispersant, the molding rate level is stable and good, and the crushing rate shows a trend of first decreasing and then increasing; the impact strength and The tensile strength shows an increasing trend and tends to be stable; therefore, a dispersant with a suitable proportion and composition (such as Example 3) can make the masterbatch have better overall performance.

[0116] The comparison of embodiment 3 and embodiment 7-14 shows: the dosage ratio between adhesive, dispersant and coupling agent has a certain influence on the performance of the material, specifically: with the increase of the dispersant dosage ratio (implementation) Examples 7-10), the molding rate of the masterbatch is relatively stable; the crushing rate increases slightly; the impact strength gradually increases; the tensile strength tends to stabilize after a slight decrease, and the appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com