Pretreatment device for boronizing internal chamber of fusion device and application of pretreatment device

A pretreatment device and boronization technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of insufficiency and damage to the vacuum environment, simplify the operation steps, and eliminate the belt of pollutants. the effect of entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

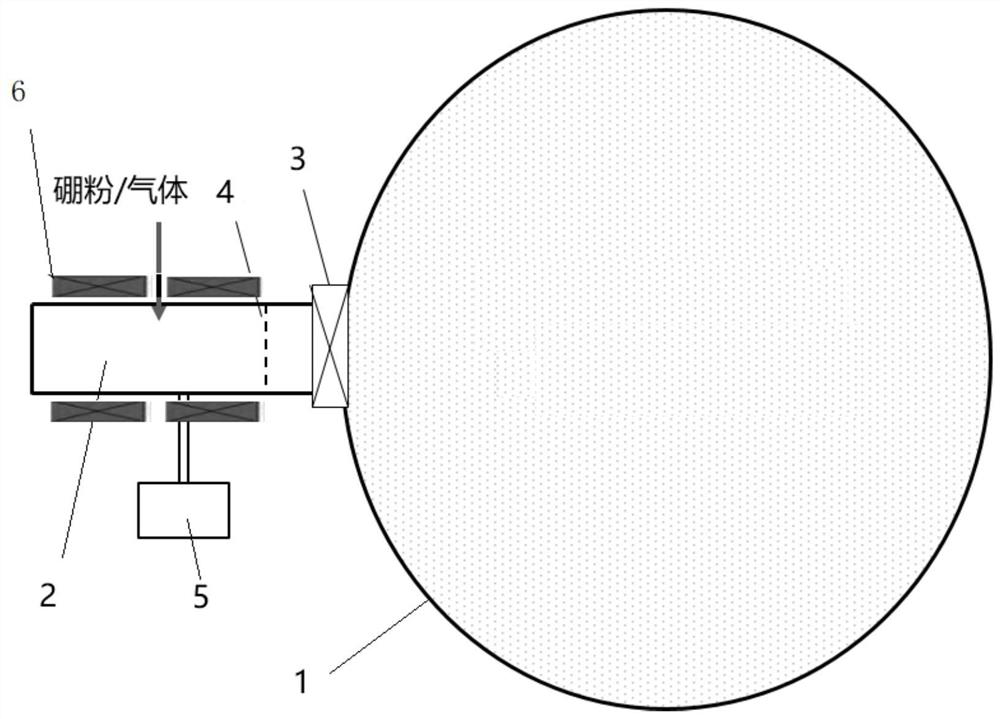

[0057] With the flapper valve closed, helium gas was introduced into the pre-ionization chamber to control the air pressure to 0.5Pa, and then the 13.56MHz radio frequency power supply was turned on to generate stable plasma. After that, boron powder with a purity of 99.99% and a particle size of 50 microns was injected into it, and the injection rate was 100 mg / min.

[0058] Open the plug valve, and through the visible spectrometer installed on the vacuum chamber of the fusion device, obvious boron spectral lines can be seen, indicating that the boron ions have entered the vacuum chamber of the fusion device, and the boronization function has been realized.

Embodiment 2

[0060] When the flapper valve is closed, hydrogen gas is introduced into the pre-ionization chamber, the air pressure is controlled to 0.06Pa, and then the 13.56MHz radio frequency power supply is turned on to generate stable plasma. After that, boron powder with a purity of 99.99% and a particle size of 70 microns was injected into it, and the injection rate was 150 mg / min.

[0061] Open the plug valve, and through the visible spectrometer installed on the vacuum chamber of the fusion device, obvious boron spectral lines can be seen, indicating that the boron ions have entered the vacuum chamber of the fusion device, and the boronization function has been realized.

Embodiment 3

[0063] With the flapper valve closed, helium gas was introduced into the pre-ionization chamber to control the air pressure to 0.05Pa, and then the 13.56MHz radio frequency power supply was turned on to generate stable plasma. After that, boron powder with a purity of 99.99% and a particle size of 90 microns was injected into it, and the injection rate was 100 mg / min.

[0064] Open the plug valve, and through the visible spectrometer installed on the vacuum chamber of the fusion device, obvious boron spectral lines can be seen, indicating that the boron ions have entered the vacuum chamber of the fusion device, and the boronization function has been realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com