Carbon fiber jacket for pounding head of furnace pounding machine

A carbon fiber and stoking machine technology, applied in inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problems of loss of stoking iron rods, affecting the use effect of stoking machines, etc., to achieve low cost, reduce iron content, Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

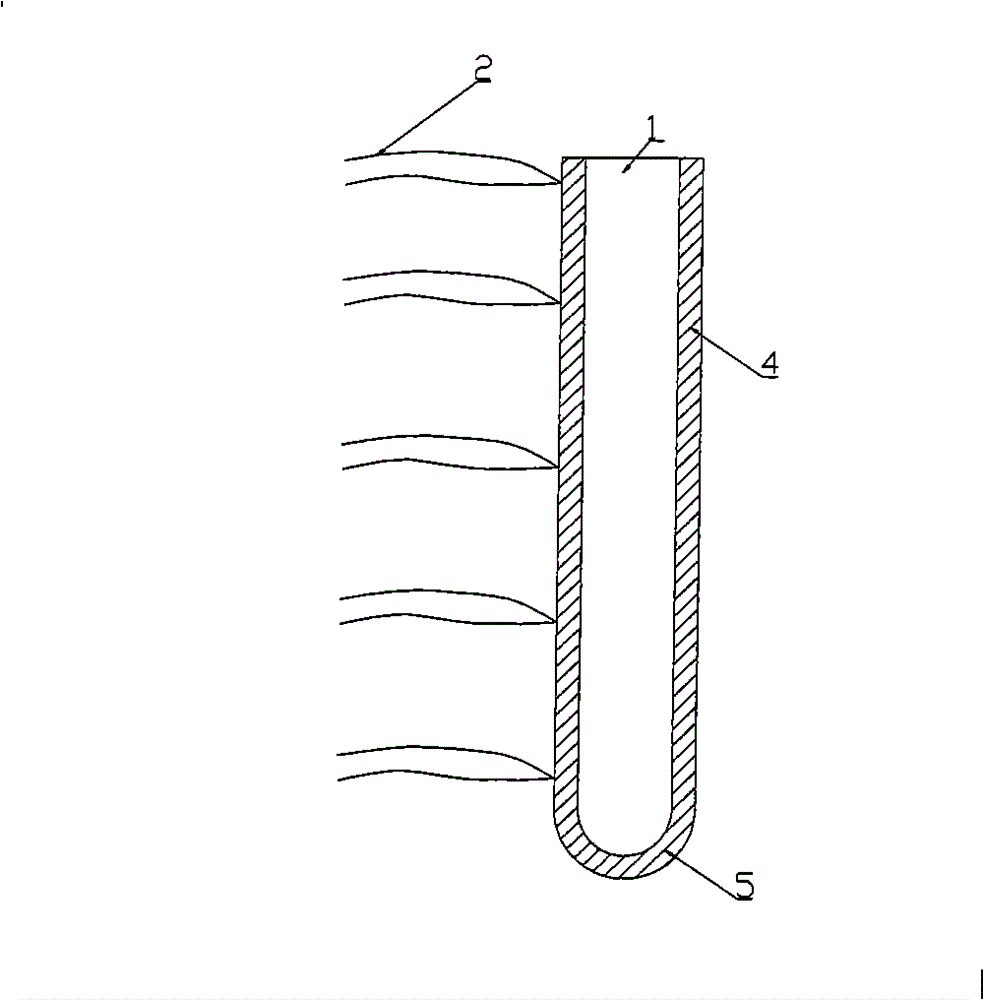

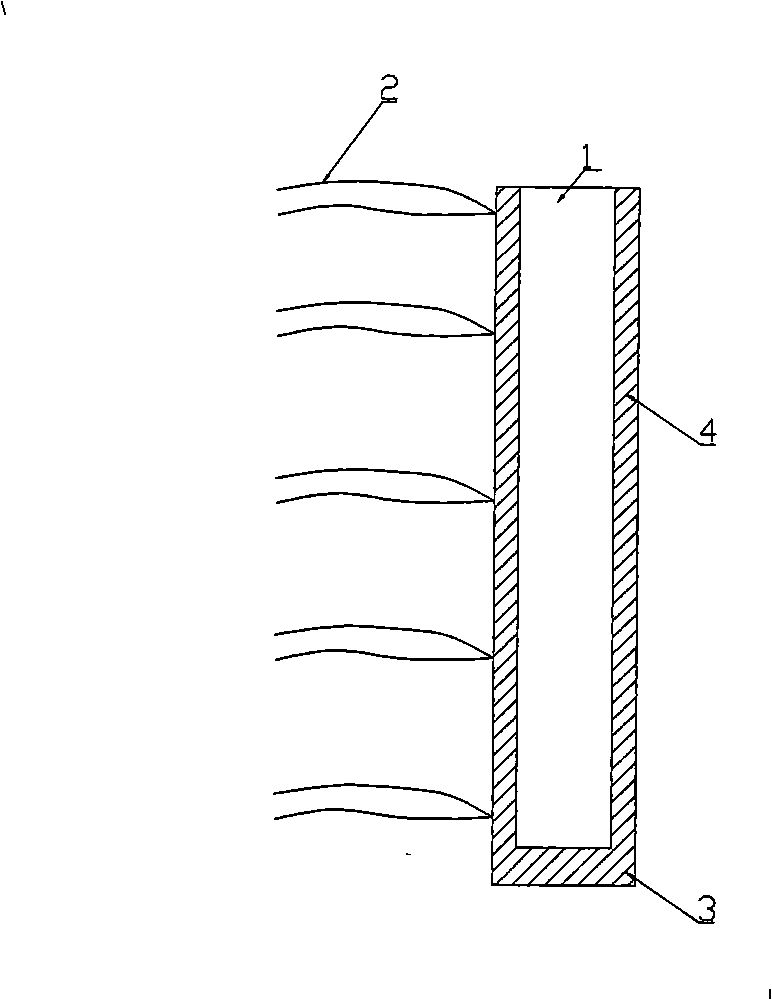

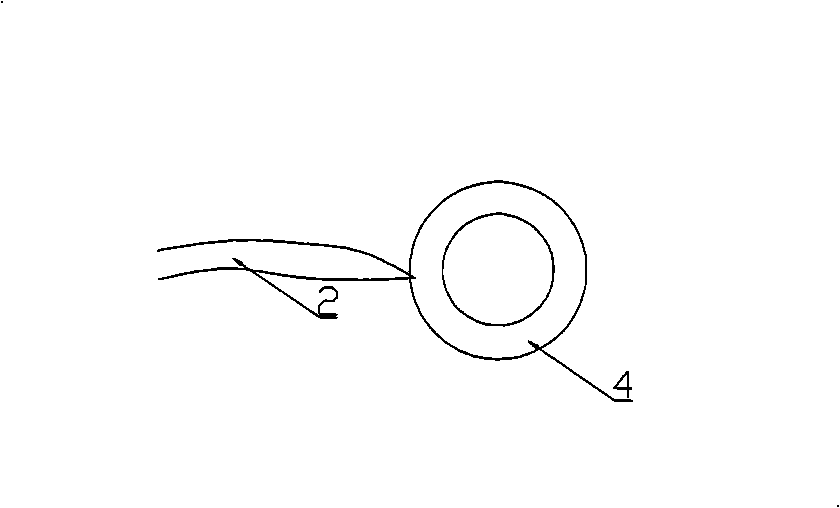

[0020] The specific implementation will be described in detail below in conjunction with the accompanying drawings: a carbon fiber overcoat for the tamping head of the furnace smelter, which is special in that: the tamping head of the furnace smelter is covered with a carbon fiber overcoat 1 matching its shape, so One end of the jacket is a closed structure 2, and the other end is an open structure 3. The open end makes it easy to slide over the tamper.

[0021] Figure 1 ~ Figure 3 A cross-sectional schematic diagram of the carbon fiber jacket used when the ramming head of the ramming machine is a ramming rod. The tamping head of the furnace smelter is a furnace rod, and the carbon fiber jacket matched with it is a hollow cylinder, and the jacket is placed on the furnace rod. Quantity of carbon fiber rope. The shape of the end of the tamping head can be hemispherical or cylindrical, and the shape of the end of the overcoat matches the shape of the tamping head. Carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com