Zero-asbestos acrylate rubber-based synthetic brake shoe and its preparation method and use

An acrylic and synthetic brake shoe technology, which is applied in mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problems of sepiolite easy to absorb moisture, cracks in products, and air bubbles in semi-finished products, so as to improve the comprehensive mechanical properties , Improving the brittleness of the friction body and the effect of good friction and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

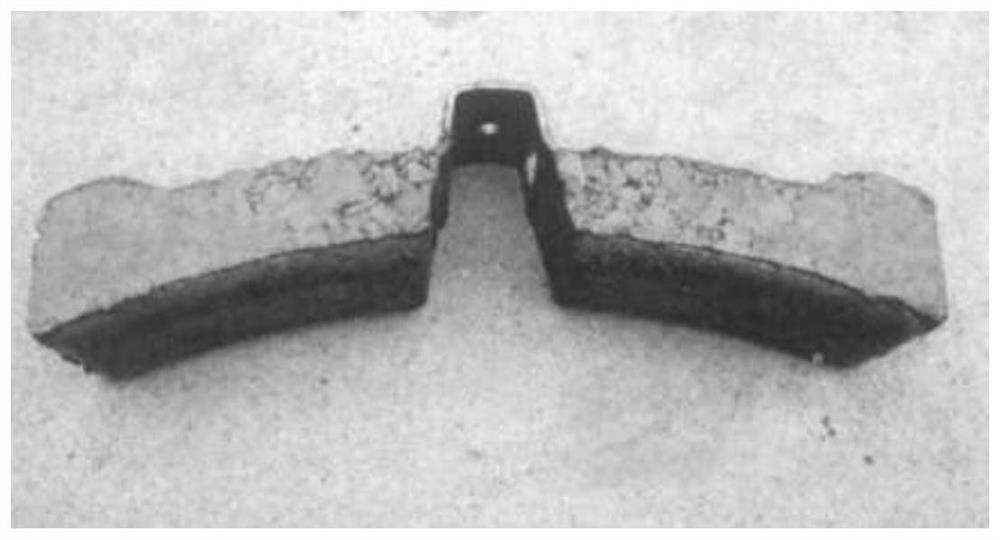

Image

Examples

Embodiment 1-10

[0049] Prepare the synthetic brake shoe according to each raw material shown in Table 1 and its corresponding amount, and the preparation method adopted is as follows:

[0050] (a) take by weighing the raw material of the formula amount shown in table 1, place on the twin-roll rubber mixer, carry out plasticizing and mixing successively;

[0051] (b) placing the kneaded material obtained in step (a) on a high-speed mixer, mixing at a speed of 800 rev / min for 1 minute, and then mixing at a speed of 1400 rev / min for 5 minutes;

[0052] (c) putting the material obtained in step (b) into a mold at 160 to 165° C. to press and unmold;

[0053] (d) heating the product obtained in step (c) to 120°C at a heating rate of 1°C / min in an oven, then drying at 120°C for 1 hour, drying at 130°C for 1 hour, and drying at 150°C for 2 hours , 160 ℃ drying for 4 hours, naturally cooled to below 80 ℃, discharging to obtain the corresponding synthetic brake shoe.

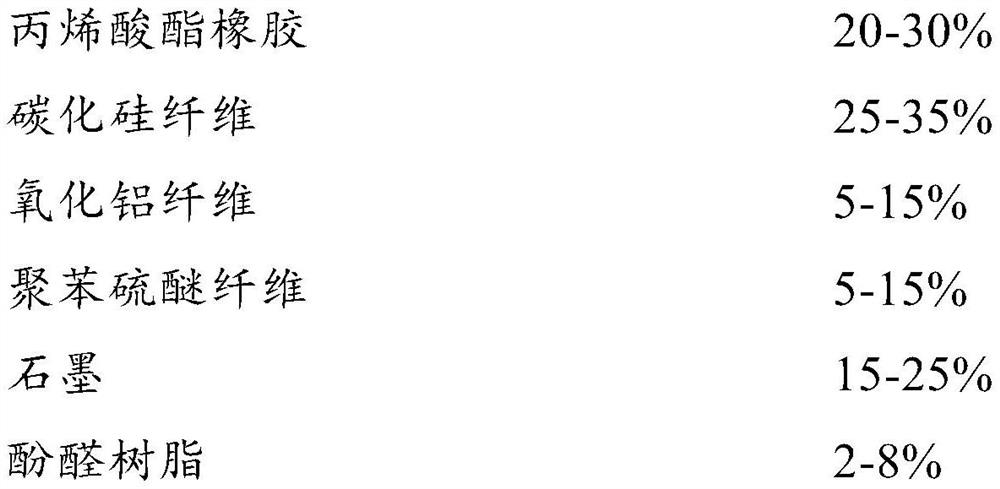

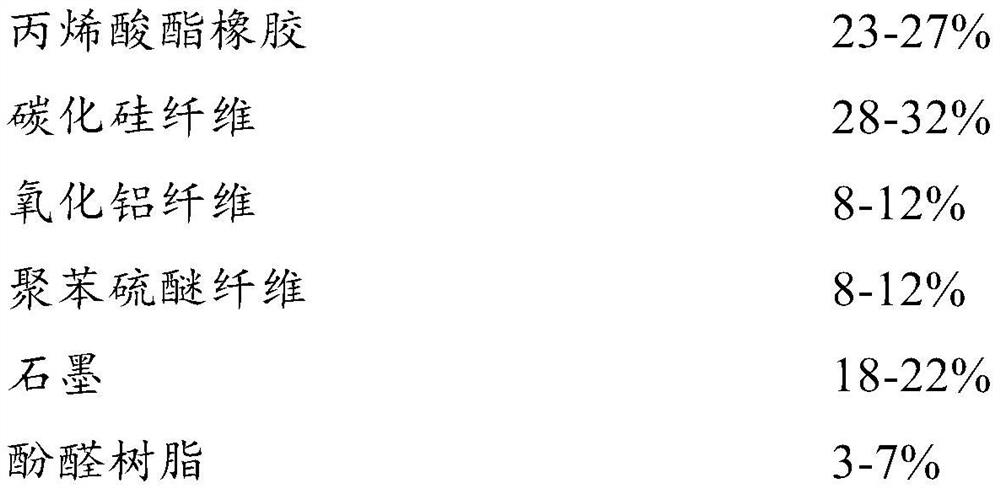

[0054] Table 1:

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com