Device and process for dynamically and continuously preparing polycarbonate

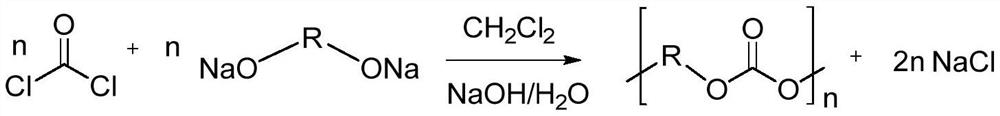

A polycarbonate, dynamic technology, applied in the field of dynamic continuous preparation of polycarbonate, can solve the problem of unstable molecular weight and molecular weight distribution of batch products, low mass transfer and heat transfer efficiency of polycarbonate, and difficult operation of polymerization process, etc. problems, to achieve precise and controllable molecular weight and molecular weight distribution, low production costs, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

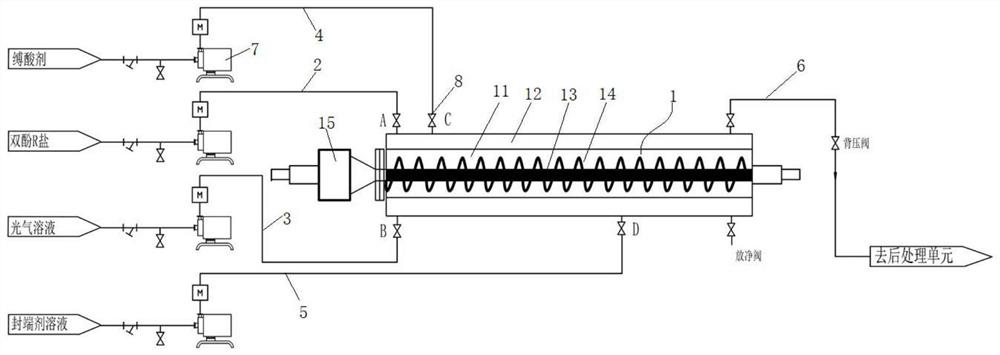

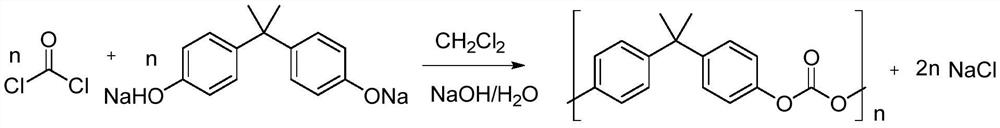

[0051] This embodiment provides a process for the dynamic continuous preparation of polycarbonate, which is realized by the above-mentioned device for dynamic continuous preparation of polycarbonate. In this embodiment, bisphenol A: phosgene: end-capping agent and acid binding agent The molar ratio of bisphenol A is 1:1.19:0.08:2.39 (the ratio of sodium hydroxide includes the amount used for the preparation of bisphenol A sodium salt), which specifically includes the following steps:

[0052] Step 1: The 30°C bisphenol A sodium salt aqueous solution, the -10°C phosgene solution and the 25°C acid binding agent sodium hydroxide aqueous solution were injected into the dynamic continuous flow reactor from feed ports A, B and C through a metering pump, respectively, Carry out a polymerization reaction, including three reaction processes of photochemistry, prepolymerization and polycondensation; reaction temperature: 41 ° C; bisphenol A sodium salt aqueous solution flow rate at 96g / m...

Embodiment 2

[0055] This embodiment provides a process for the dynamic continuous preparation of polycarbonate, which is realized by the above-mentioned device for dynamic continuous preparation of polycarbonate. In this embodiment, bisphenol A: phosgene: end-capping agent and acid binding agent The molar ratio of bisphenol A is 1:1.19:0.115:2.39 (the ratio of sodium hydroxide includes the amount used for the preparation of bisphenol A sodium salt), which specifically includes the following steps:

[0056] Step 1: The 25°C bisphenol A sodium salt aqueous solution, the -10°C phosgene solution and the 25°C acid binding agent sodium hydroxide aqueous solution are respectively injected into the dynamic continuous flow reactor from feed ports A, B and C through a metering pump, Carry out a polymerization reaction, including three reaction processes of photochemistry, prepolymerization and polycondensation; reaction temperature: 41.5 ° C; bisphenol A sodium salt aqueous solution flow rate at 960g...

Embodiment 3

[0059] This embodiment provides a process for the dynamic continuous preparation of polycarbonate, which is realized by the above-mentioned device for dynamic continuous preparation of polycarbonate. In this embodiment, bisphenol A: phosgene: end-capping agent and acid binding agent The molar ratio of bisphenol A is 1:1.19:0.3286:2.39 (the ratio of sodium hydroxide includes the amount used for the preparation of bisphenol A sodium salt), which specifically includes the following steps:

[0060] Step 1: The 25°C bisphenol A sodium salt aqueous solution, the -10°C phosgene solution and the 25°C acid binding agent sodium hydroxide aqueous solution are respectively injected into the dynamic continuous flow reactor from feed ports A, B and C through a metering pump, Carry out a polymerization reaction, including three reaction processes of photochemistry, prepolymerization and polycondensation; reaction temperature: 41°C; bisphenol A sodium salt aqueous solution flow rate is 192g / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com