Antibacterial cutter and manufacturing method of antibacterial cutter

A manufacturing method and cutting tool technology, applied in solid diffusion coating, coating, metal processing and other directions, can solve the problems of reducing the hardness of the cutting tool, adding a large amount of antibacterial ingredients, and increasing the manufacturing cost, so as to improve the bonding force and excellent antibacterial effect. , the effect of strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] Antibacterial Knives

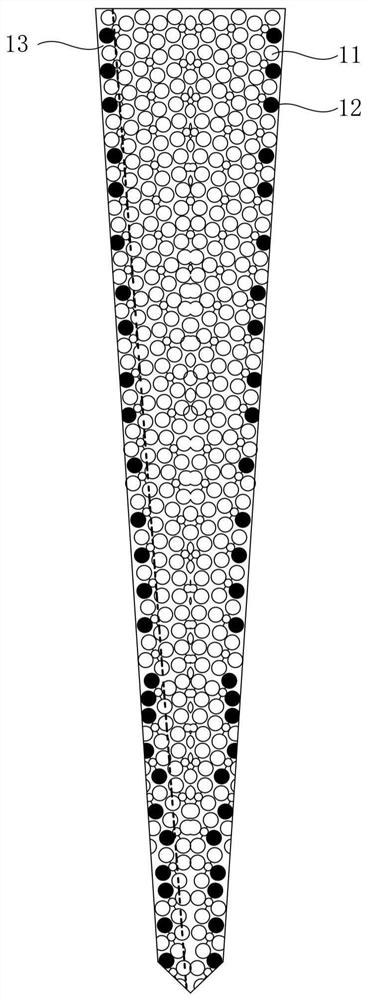

[0041] like figure 2 As shown, the antibacterial knife 10 according to the first embodiment of the present disclosure may include a knife body 11, a predetermined depth from the surface of the knife body 11 to the inside of the knife body 11 is the infiltration layer 13 infiltrated with the antibacterial agent 12, the thickness of the infiltration layer 13 In the penetration layer 13, the area occupied by the antibacterial agent 12 per unit area is 2‰~2% of the unit area.

[0042] According to an embodiment of the present disclosure, the cutter body 11 may be martensitic stainless steel. As an example, the martensitic stainless steel can be, for example, 2Cr13, 3Cr13, 4Cr13, and 5Cr15, etc., and preferably can be 3Cr13 and 5Cr15. However, it should be understood that the material of the cutter body 11 of the embodiment of the present disclosure is not limited by the above materials. According to an embodiment of the present disclosure, the a...

no. 2 example

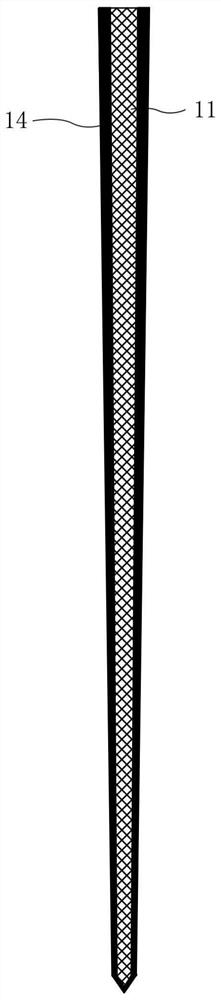

[0085] Antibacterial Knives

[0086] like image 3 As shown, the antibacterial knife 10 according to the second embodiment of the present disclosure may include a knife body 11 containing a titanium alloy, and on the surface of the knife body 11, titanium in the titanium alloy is oxidized in-situ to form titanium dioxide, so as to be A titanium dioxide layer 14 is formed on the surface of the main body 11 , wherein, in the titanium dioxide layer 14 , the weight of titanium dioxide is greater than or equal to 95% of the weight of the titanium dioxide layer 14 .

[0087] According to an embodiment of the present disclosure, the cutter body 11 may include a titanium alloy, which refers to an alloy metal made of titanium and other metals. According to an embodiment of the present disclosure, the titanium alloy may include TA4˜TA20 described in Chinese standard GBT3620.1-2007. According to the embodiment of the present disclosure, since the titanium alloy is used as the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com