High-strength plastic titanium alloy suitable for cold deformation processing and preparation method thereof

A cold deformation, titanium alloy technology, applied in the field of titanium alloy materials, can solve the problems of difficult cold deformation processing, large material loss, and high production cost, and achieves the problem of overcoming large deformation cold working, excellent strong plastic matching, and excellent cold deformation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The high-strength and high-plastic titanium alloy in this embodiment is composed of the following components by weight: Mo 4.23%, Cr 2.90%, Fe 0.80%, O<0.18%, and the balance is Ti and inevitable impurities. In this example, through reasonable component design, only five elements including Ti, Mo, Cr, Fe and O are included, and the addition of α-stabilizing elements such as Al and Sn is avoided. The content of α phase and the distribution of alloying elements in α and β phases obtain α+β two-phase titanium alloy, which can reduce the cost and improve the plastic workability of the alloy, so that the alloy has excellent strong-plastic matching.

[0046] The preparation method of the high-strength and high-plastic titanium alloy in this embodiment comprises the following steps:

[0047] S1 prefabricated electrode: 1.32kg Ti-32Mo master alloy, 0.3kg chromium flakes and 0.09kg iron particles are evenly mixed, and the mixture is placed in the middle of 8.29kg titanium sponge...

Embodiment 2

[0055] The ingot obtained in step S2 in Example 1 was opened and forged into a square billet, then placed in a resistance furnace and heated to 740° C. for 1 hour, and then multi-pass rolling was performed to remove the surface oxide layer and clean it to obtain a titanium alloy rolled. plate; in the multi-pass rolling process, after each pass, the titanium alloy forging billet is placed in a resistance furnace and heated to 740 ° C and kept for 10 minutes; the total deformation of the multi-pass rolling is 80 %.

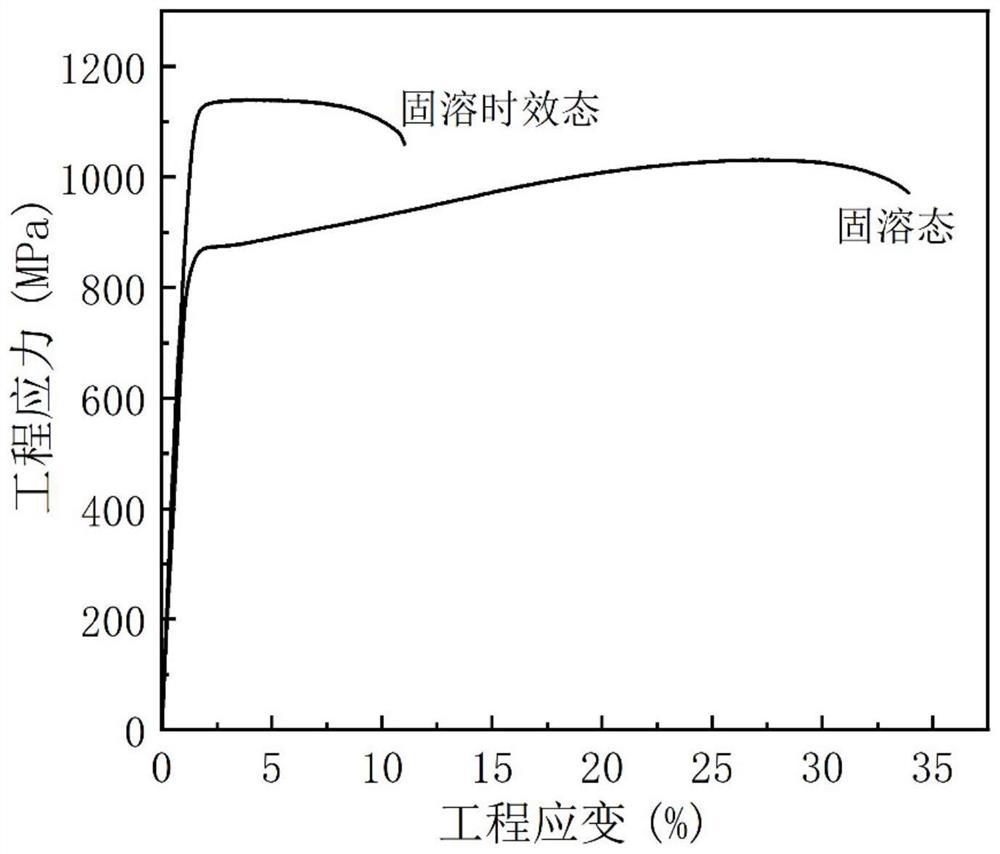

[0056] The as-rolled alloy was solution-treated at 750°C / 30min, and then water-cooled to room temperature. The obtained solid-solution microstructure contained about 10% equiaxed α phase, with a tensile strength of 1168MPa and an elongation of 36.2%. .

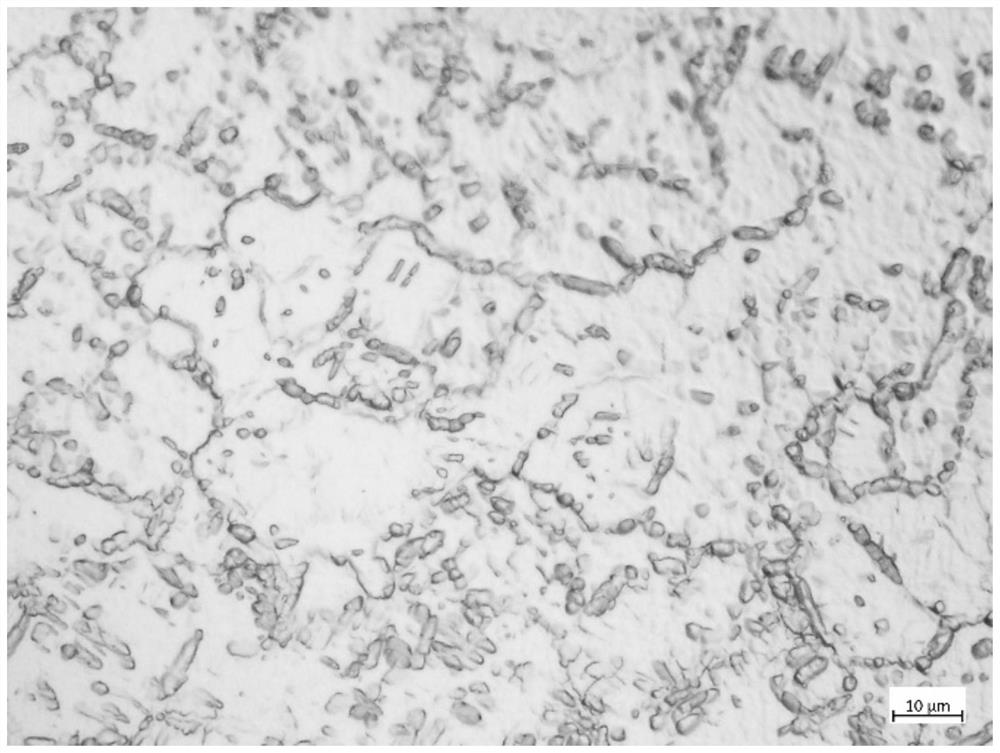

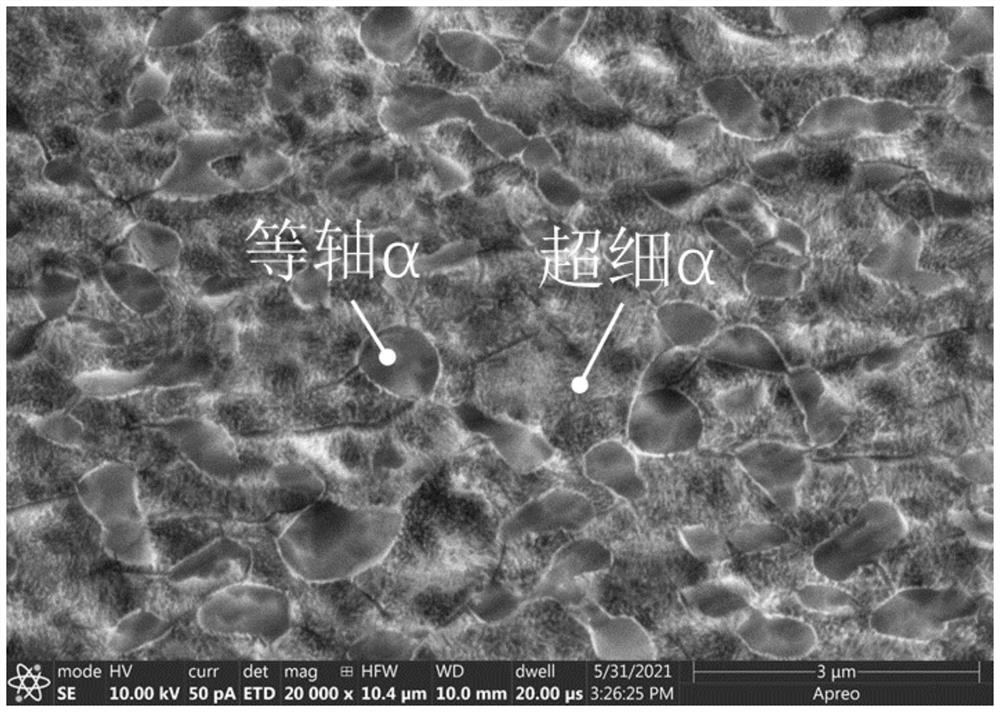

[0057] The solid-solution alloy was artificially aged at 480 °C for 4 hours, and the aging microstructure obtained was a dual-state microstructure, such as image 3 As shown, it contains a primary equiaxed α phase...

Embodiment 3

[0059] The present embodiment is a preparation method of a cold-rolled sheet, and the specific steps are:

[0060] S1: The solid solution forging billet obtained in step S4 of Example 1 is machined into a slab.

[0061] S2: The slab in step S1 is kept at 650°C for 30 minutes to adjust the content and element distribution of α and β phases in the structure, and then water-cooled and quenched to room temperature; rolling is directly heat-treated at 650°C in the forged state.

[0062] S3: removing the oxide scale from the slab in step S2 and cleaning, and performing multiple passes of cold rolling deformation at room temperature, the total deformation is greater than 85%, and a plate with a thickness of 1.5mm is obtained; Figure 5 a is the appearance of the cold-rolled sheet, and it can be seen that the surface quality is good.

[0063] S4: Aged the S3 cold-rolled sheet at 460° C. for 1 h, the tensile strength is 1460 MPa, and the elongation is 8.3%.

[0064] S5: The S3 cold-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com