Method for preparing gradient Nb-Si-based alloy film by adopting multi-target co-deposition magnetron sputtering high-flux technology

A magnetron sputtering and co-deposition technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problem of reducing the mechanical properties of Nb-Si based alloys, the large variation range of Cr element content, Reduce the alloy's high-temperature oxidation resistance and other problems, and achieve the effect of increasing Si element content, high purity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

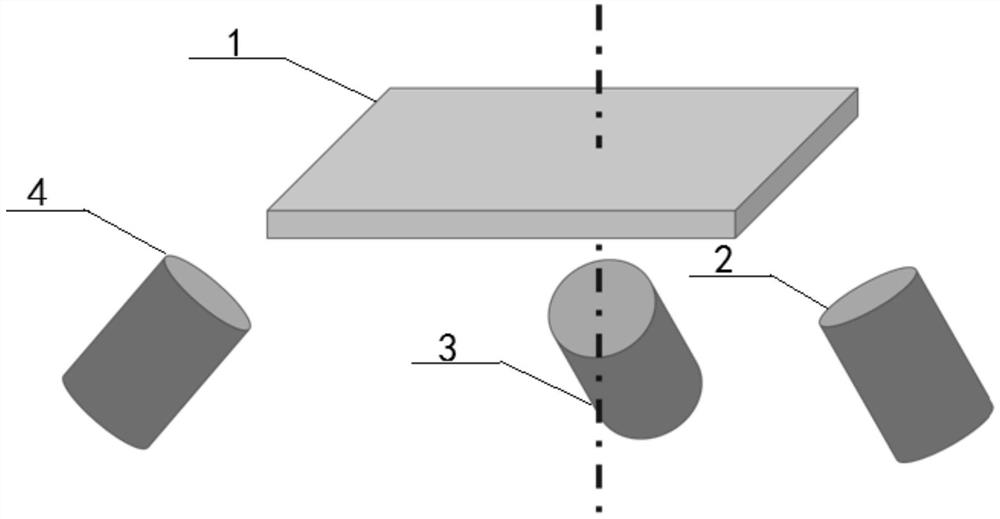

[0059] A method for preparing a high-purity gradient Nb-Si-based alloy thin film by using multi-target co-deposition magnetron sputtering high-throughput technology, comprising the following steps:

[0060] 1) Using Nb, B, Ti, and Al as synthetic raw materials, xNb-yB-zTi-kAl alloy target 4 is prepared by magnetic levitation induction melting, wherein x=61, y=7, z=26, k=6, numerical value All are atomic percent. Then cut into Φ60mm×5mm size.

[0061] 2) Using Si and Cr as raw materials respectively, using vacuum non-consumable arc melting technology to prepare Si ingots and Cr ingots, placing them in an electron beam melting furnace for electron beam purification, and then cutting them into sizes of Φ60mm×5mm. High purity Si target and Cr target.

[0062] a) The Cr target material 2, Si target material 3 obtained in step 2) and the 61Nb-7B-26Ti-6Al (at.%) alloy target material obtained in step 1) are polished with 60# water abrasive paper to remove surface oil;

[0063] b) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com