Embossing roller with micro-nano dual-scale structure on surface as well as preparation method and application of embossing roller

A technology of micro-nano structure and embossing roller, which is applied in the field of leather manufacturing, can solve the problems of difficult surface control of embossing rollers, high equipment cost, shallow engraving depth, etc., to improve embossing uniformity and touch texture, nanoscale The effect of simple control and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

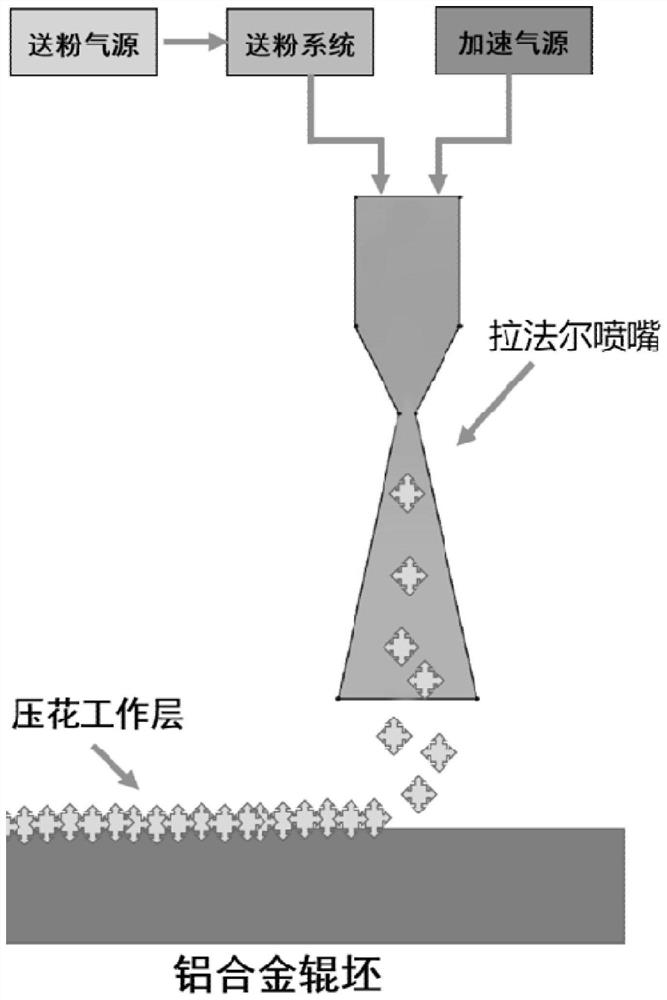

[0020] In a first aspect, the present invention provides a method for preparing an embossing roll with a micro-nano dual-scale structure on the surface, comprising transferring powder with a micro-nano dual-scale structure to the surface of the embossing roll blank to form micro-nano bi-scale structures by supersonic collision deposition. Nanostructured coating, wherein the roll blank of the embossing roll is made of aluminum alloy.

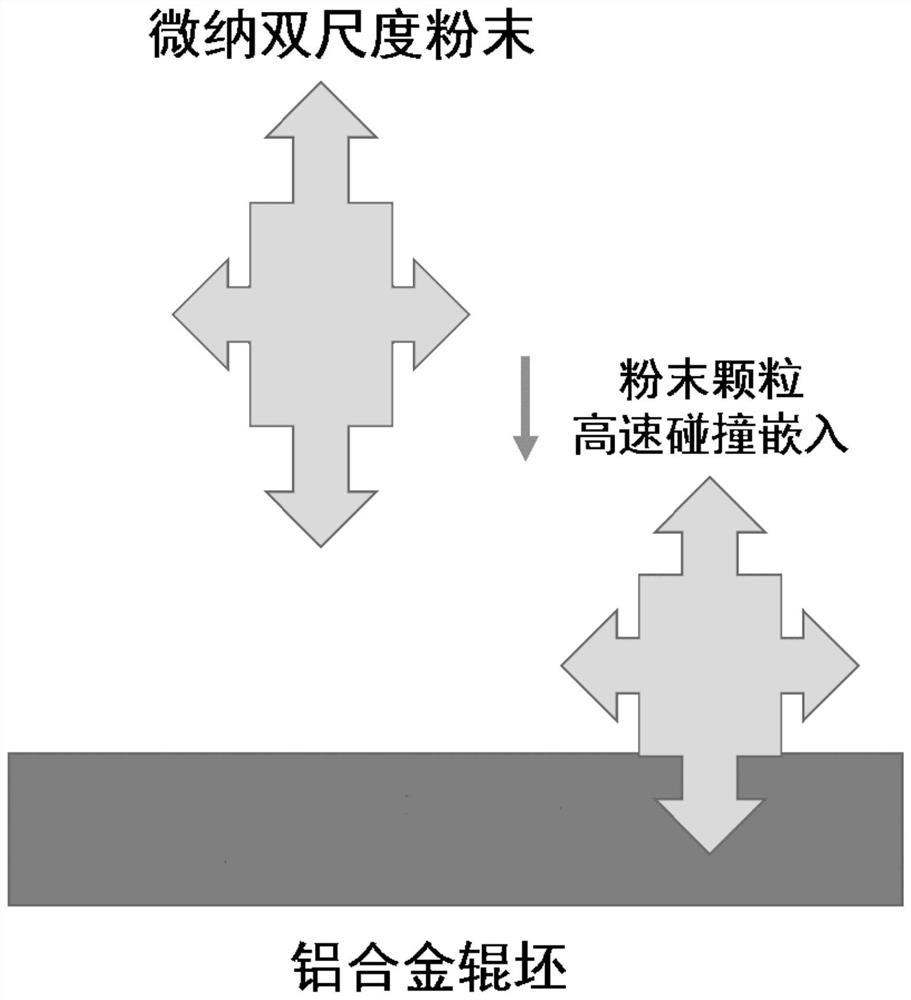

[0021] The powder with the micro-nano dual-scale structure is a three-dimensional powder with multiple tree-shaped branches on the surface. Due to its special morphology, when it is attached to the surface of the substrate, it can make the surface of the substrate form uneven microscopic. Nanostructure coating, which greatly improves the texture formation and touch texture of leather.

[0022] The invention adopts the supersonic collision deposition technology to directly plant the powder with the micro-nano double-scale structure on the surface ...

Embodiment 1

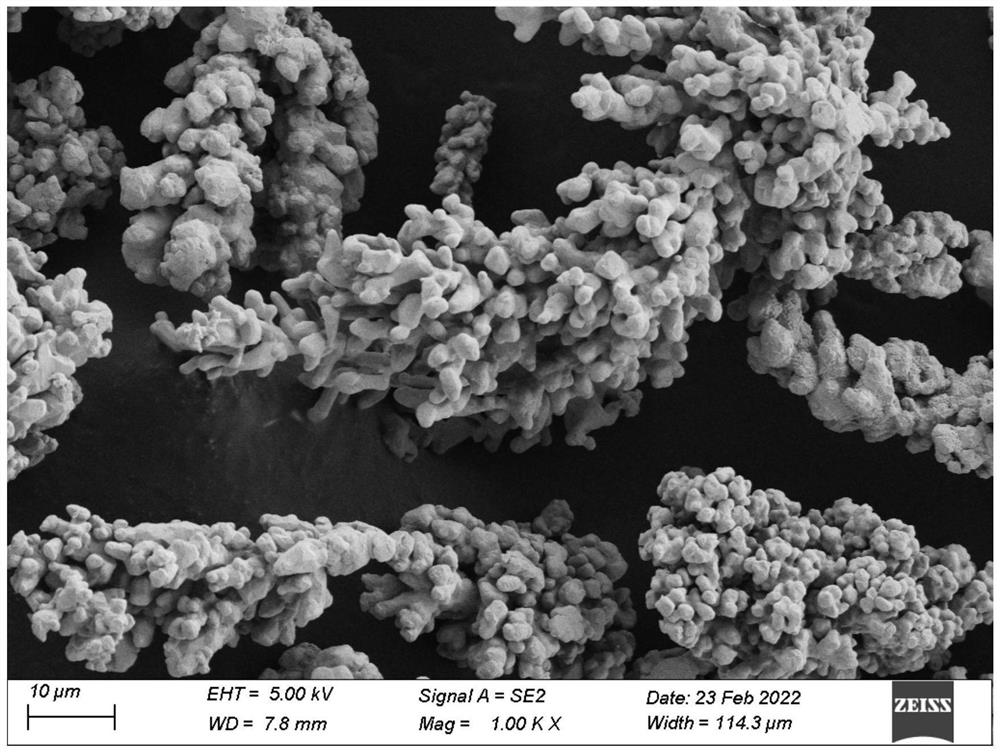

[0052] This embodiment provides an embossing roll, the roll blank is 6061 aluminum alloy, the powder with micro-nano dual-scale structure is pure nickel powder, and the powder structure is as follows image 3 As shown, its preparation method is as follows:

[0053] S1, roll blank pretreatment

[0054] Use 80-2000 mesh sandpaper to polish the surface of the roll blank in turn. The number of sandpaper meshes for each grinding should be greater than the number of sandpapers for the previous grinding, and the traces of the previous grinding should be removed for each grinding.

[0055] After grinding, use a polishing cloth to polish the surface of the roll blank until the roughness of the roll blank surface is 0.8 μm, to ensure that the powder with the micro-nano dual-scale structure can be completely and uniformly sprayed on the roll blank surface.

[0056] Use acetone to clean the polished roll blank to remove the debris remaining on the surface of the roll blank during the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com