Ultrasonic waste paper deinking pretreatment device

A pretreatment device, waste paper deinking technology, applied in fiber raw material treatment, papermaking, paper recycling, etc., can solve the problems of large water consumption and low production efficiency of waste paper deinking, achieve small particle size, reduce subsequent chemical The effect of product usage and excellent deinking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The ultrasonic waste paper deinking pretreatment device of the present invention can be made of the following materials and components, and is not limited to the following materials and components, such as: ultrasonic transducers, conveyor belts, rubber plates, rollers, ultrasonic vibration plates, hard plates Alloy plates, etc.

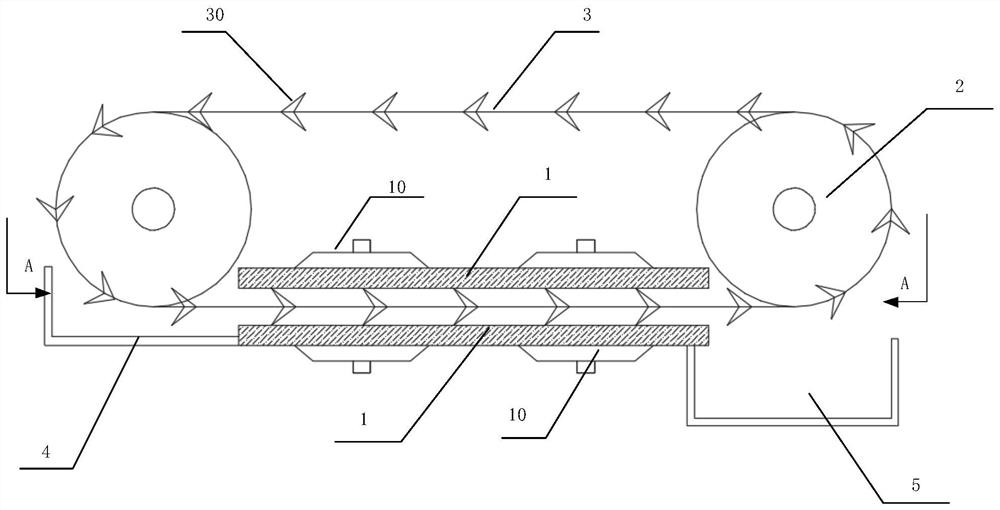

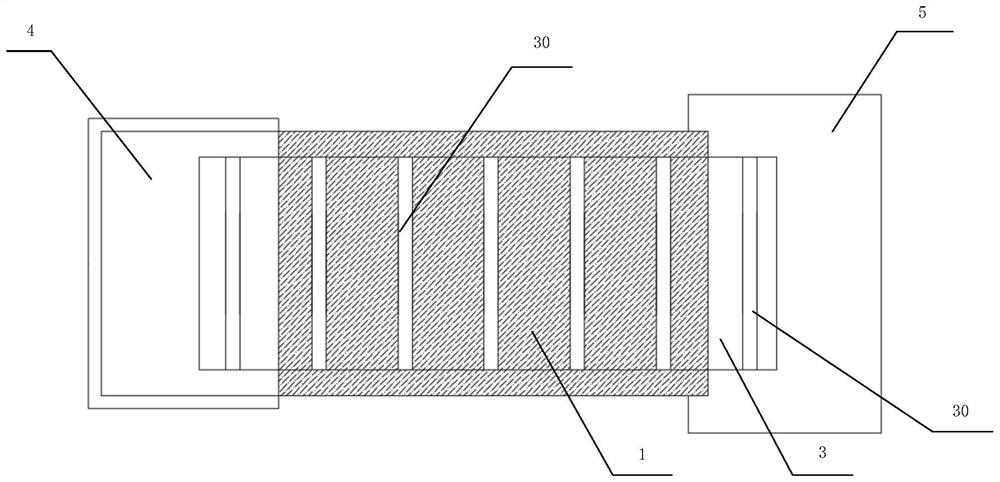

[0023] like figure 1 Shown is the side structure diagram of the ultrasonic waste paper deinking pretreatment device of the embodiment of the present invention; and refer to figure 2 .

[0024] The ultrasonic waste paper deinking pretreatment device in this embodiment includes: a conveyor belt and two metal hard plates 1; the metal hard plates 1 are generally made of high-hardness alloy steel, and are used for installing ultrasonic vibration plates or ultrasonic transducers The thickness of the metal hard plate 1 is generally 5-25mm to ensure that the energy of the ultrasonic vibration plate can be effectively transmitted.

[0025] The two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com