Detachable finned tube heat exchanger

A finned-tube heat exchanger and dismantling technology are applied in the fields of dismountable finned-tube heat exchangers, heat exchange equipment, and compressed air waste heat recovery to achieve increased disturbance capacity, strong pressure bearing capacity, and good sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solutions of the present invention will be described in more detail below through the accompanying drawings and embodiments.

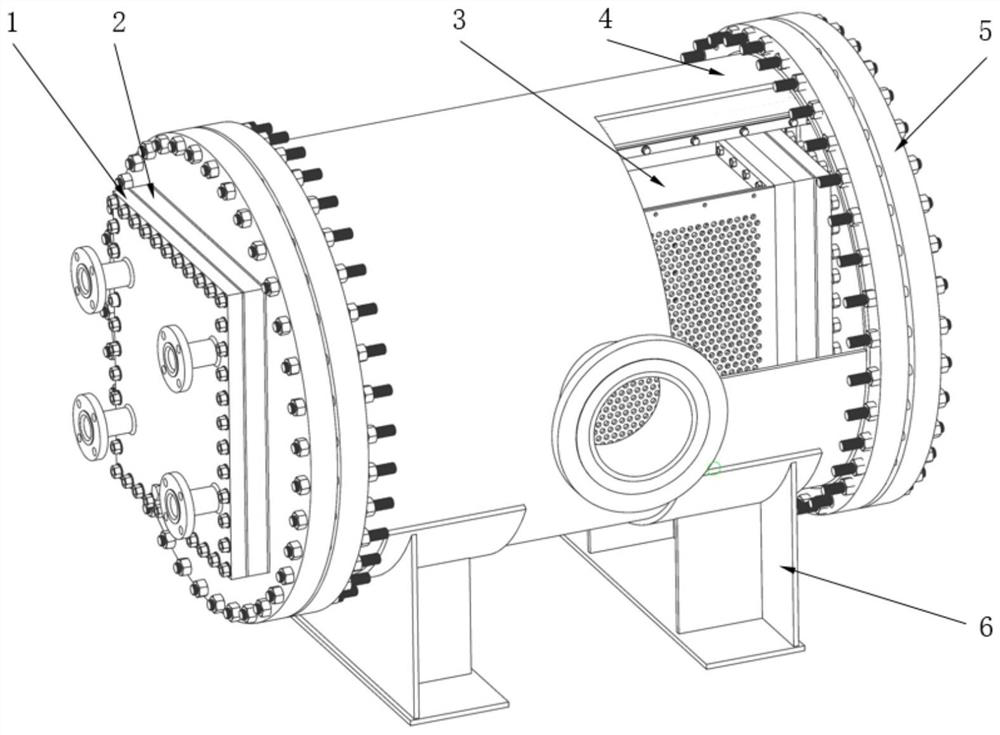

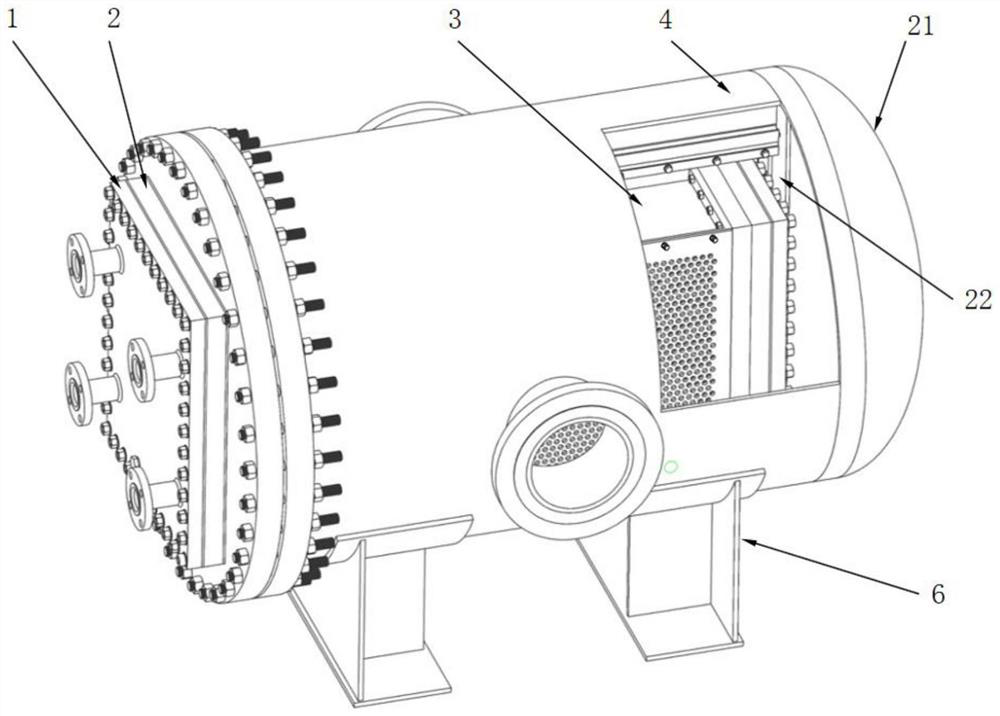

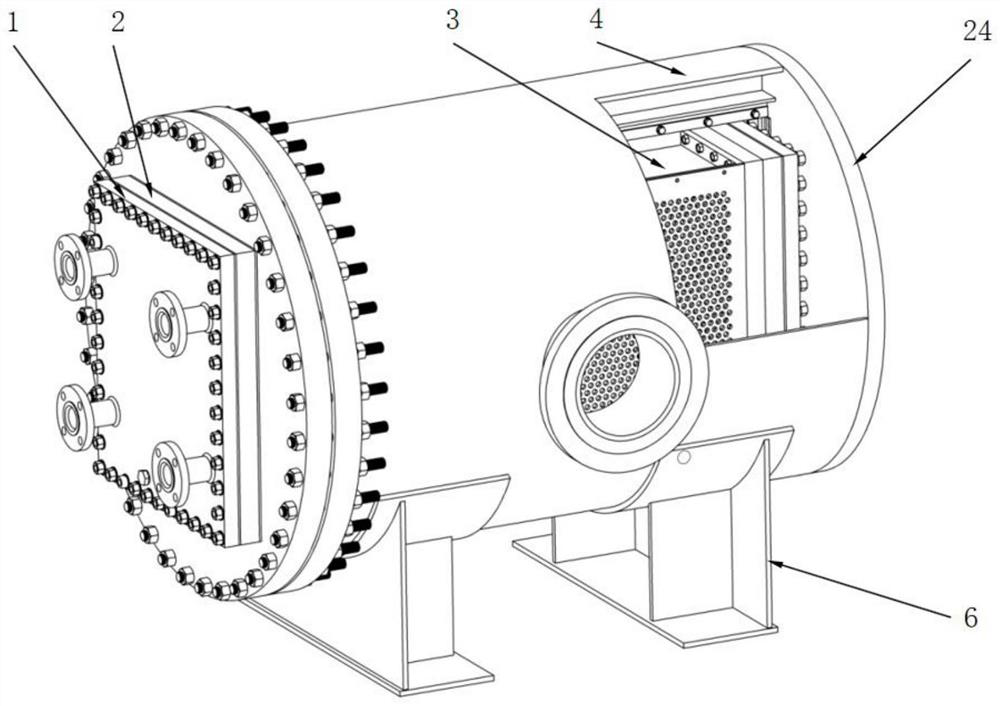

[0058] refer to Figure 1-Figure 3 , Figure 5 , Image 6 , A detachable finned tube heat exchanger disclosed in this embodiment is characterized in that it includes a water inlet and outlet cover 1, a water inlet and outlet chamber 2, a shell 4, a core group 3, and a support 6. The core group 3 It is mainly composed of fixed tube sheet 13 , fins 14 , heat exchange tubes 15 , upper sealing plate 12 , lower sealing plate 18 , movable tube sheet 11 , return water cover 9 , return water chamber 10 and gas equalization plate 16 . The water inlet and outlet cover 1 adopts the type of double inlet and double outlet to ensure the uniform flow of the medium in and out of the pipe side. The shell 4 is symmetrically provided with gas inlets and outlets, and the gas equalization plate 16 is installed on the side of the core group 3 close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com