Analysis method for actually measured pressure data in hydraulic transient process

A technology of transient process and actual pressure measurement, applied in the electric power field, can solve problems such as reducing safety risks, inversion calculation uncertainty, and inability to calculate accurately, achieving high accuracy and accurate and reliable processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] As a preferred embodiment of the present invention, the present embodiment discloses a method for analyzing measured pressure data in a hydraulic transient process, including the following steps:

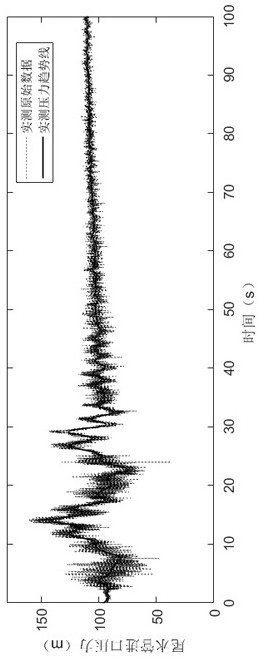

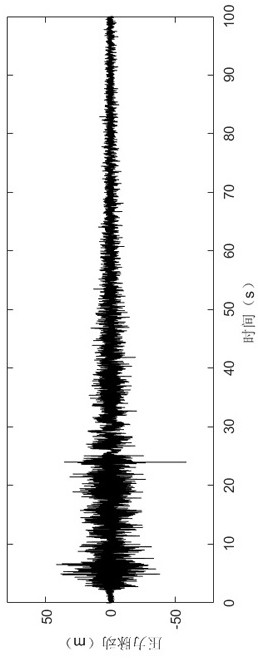

[0051] S1. Extract the data mean value from the measured data through noise reduction, and obtain instantaneous pressure fluctuation data by making a difference between the data mean value and the measured data;

[0052] S2. The obtained pressure fluctuation data is divided into time-domain grid distribution by grid division method, and in the time domain of all test data, it is divided into multiple time grid regions according to time intervals;

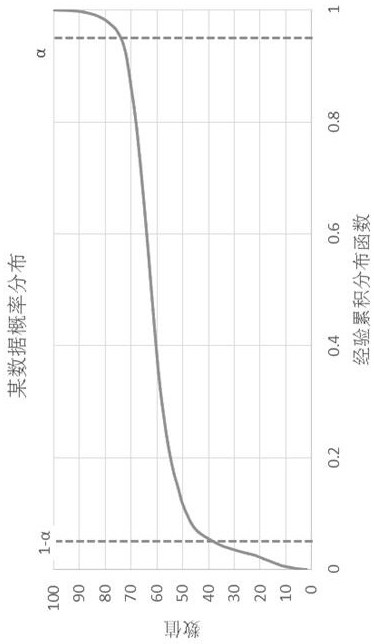

[0053] S3. Use the empirical cumulative distribution function to analyze the pressure fluctuation data in each time grid area in turn, obtain the probability distribution of each data, perform confidence probability processing, retain the data whose probability distribution is within the confidence probability range, and combine eac...

Embodiment 2

[0057] As another preferred embodiment of the present invention, refer to the appendix of the description Figure 1-6 , provides a hydraulic transient process measured pressure data analysis method, including the following steps:

[0058] S1. Extract the average pressure from the measured data through smoothing filtering, and make the difference between the average pressure and the measured data to obtain instantaneous pressure fluctuation data;

[0059] S2. Use the grid division method to divide the obtained pressure fluctuation data into time-domain grid distribution. In the time domain of all the test data, it is divided into multiple time-grid areas according to time intervals, and the time-grid areas are set to overlap calculation time, the overlap calculation time is considered according to the data overlap rate, and the data overlap degree is expressed in percentage. Generally speaking, the higher the overlap degree, the higher the accuracy of data processing;

[0060]...

Embodiment 3

[0065] As another preferred embodiment of the present invention, a method for analyzing measured pressure data in a hydraulic transient process is provided, comprising the following steps:

[0066] S1. Extract the average pressure from the measured data through smoothing filtering, and make the difference between the average pressure and the measured data to obtain instantaneous pressure fluctuation data;

[0067] S2. The obtained pressure fluctuation data is divided into time-domain grid distribution by grid division method, and in the time domain of all test data, it is divided into multiple time grid regions according to time intervals;

[0068] S3. Analyze the pressure fluctuation data in each time grid area in turn using the empirical cumulative distribution function inferred from the samples of multiple samples to obtain the probability distribution of each data, and exclude the probability distribution lower than 3% and higher than 97% of the data, retain the data with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com