Fatigue microcrack propagation prediction method based on EBSD characterization and crystal plasticity

A technology of crystal plasticity and prediction method, which is applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems that the micro-cracks are not relatively uniform, the influence of stress redistribution at the crack tip cannot be considered, and the local real microstructure characteristics are not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solution of the present invention will be further described below with reference to the accompanying drawings.

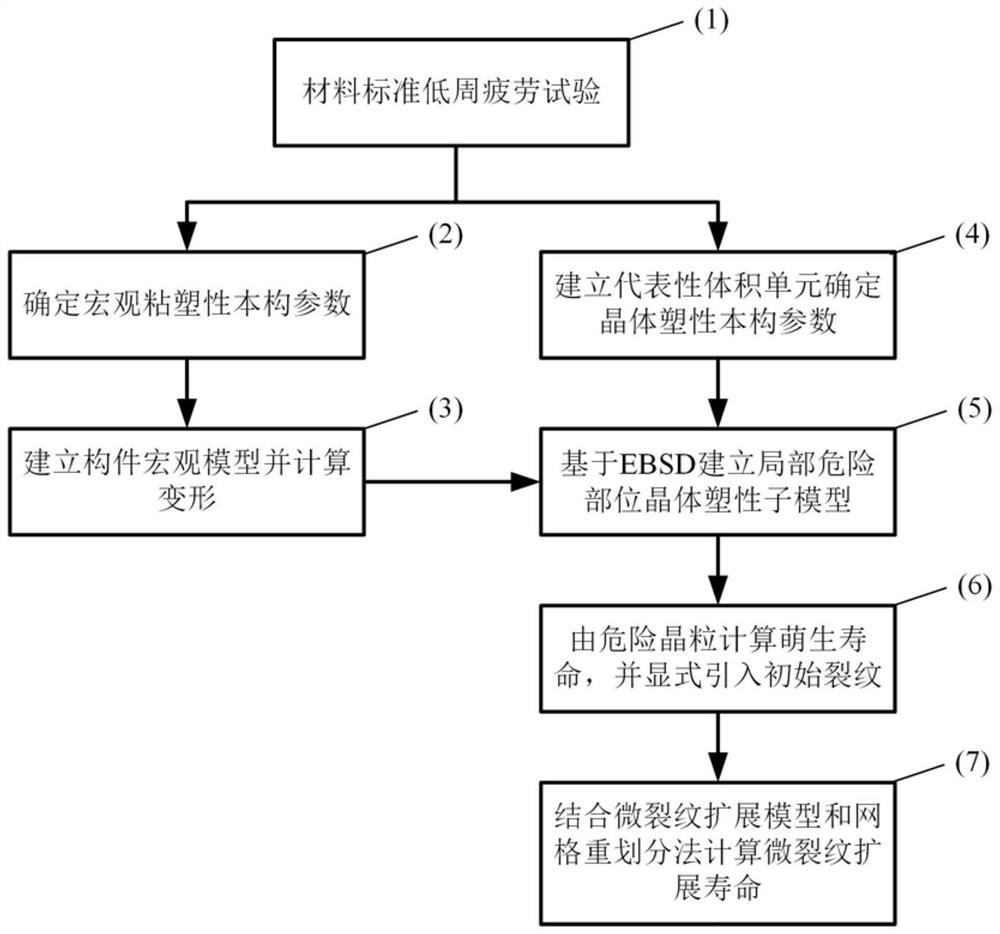

[0056] like figure 1 As shown, a fatigue micro-crack propagation prediction method based on EBSD characterization and crystal plasticity of the present invention includes the following steps:

[0057] (1) Carry out the standard low-cycle fatigue test at the service temperature of the component material, and obtain the stress-strain hysteresis loop.

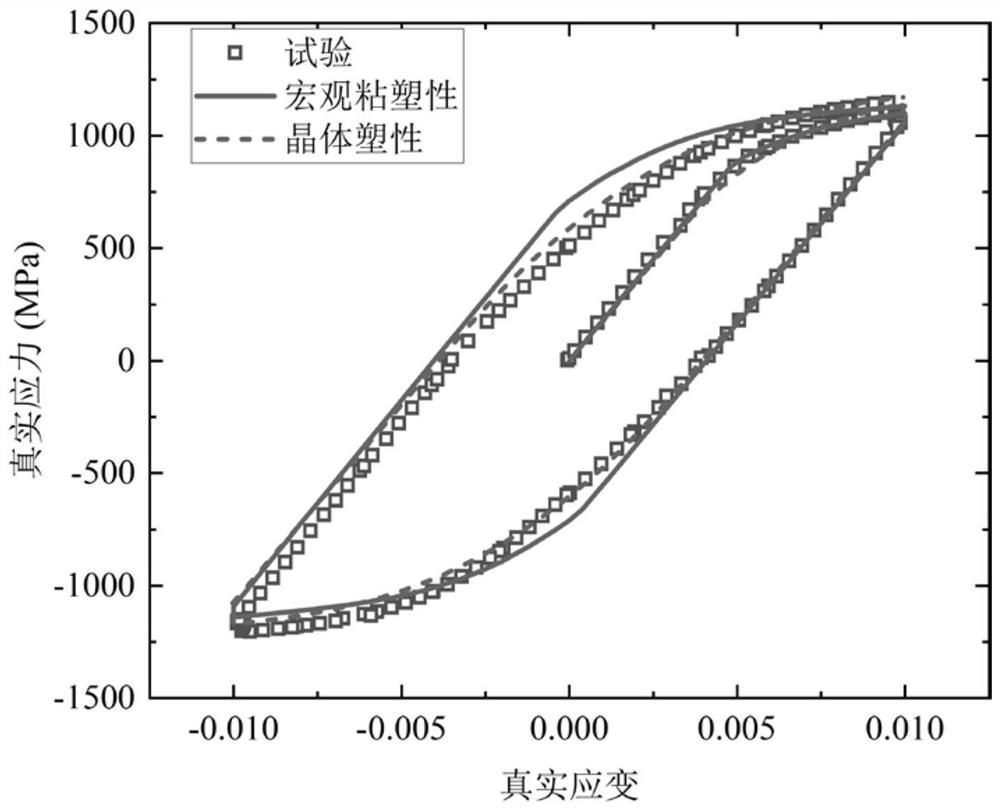

[0058] (2) The macro viscoplastic constitutive model is compiled by using FORTRAN subprogram, and the parameters of the macro viscoplastic constitutive model are determined by fitting the cubic element model to the stress-strain curve of the low-cycle fatigue test. The macroscopic viscoplastic constitutive parameter equation is as follows:

[0059] ε=ε e +ε p (1)

[0060] σ=2Gε e +λTr(ε e )I (2)

[0061] where ε,ε e and ε p are the total strain tensor, elastic strain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com