Process for preparing ethylbenzene by ethylene-containing dry gas liquid phase method

A liquid phase, dry gas technology, applied in chemical instruments and methods, hydrocarbon purification/separation, organic chemistry, etc., can solve the problems of short catalyst operation cycle, low ethylene recovery rate, and many by-products, etc., to improve safety. The effect of operational reliability, high ethylene conversion and selectivity, and increased ethylbenzene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

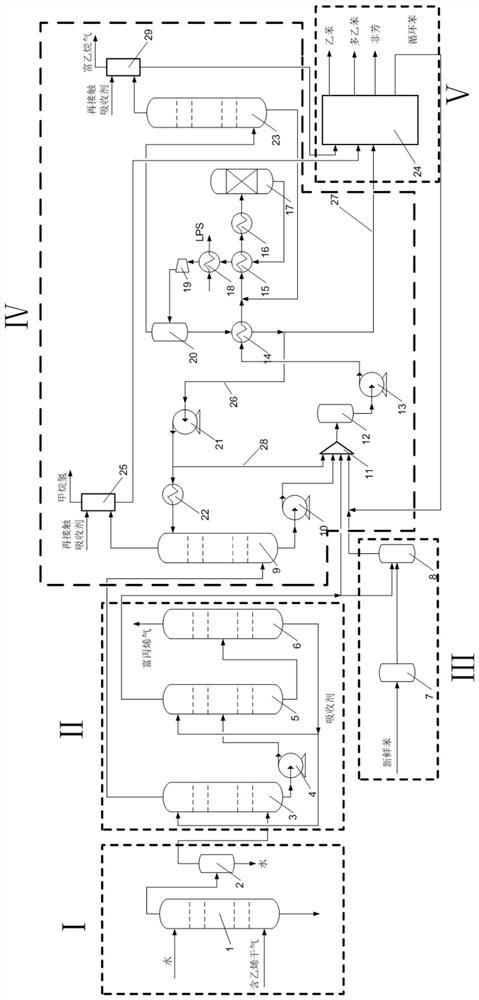

[0060] A 120,000-ton / year catalytic dry gas-liquid phase ethylbenzene production unit, using figure 1 process.

[0061] in:

[0062] The theoretical plate of the absorption tower has 15 layers, the absorption pressure is 0.9MPag, and the absorption temperature is 15℃;

[0063] The ethylene desorption tower has 15 theoretical plates, the desorption tower pressure is 1.2MPag, and the top temperature is 29℃;

[0064] The ethylene absorption tower adopts a packed tower, the absorption pressure is 0.85MPag, and the absorption temperature is 15℃;

[0065] The total benzene / total ethylene molar ratio of the alkylation reaction unit feed is 3.2:1;

[0066] Alkylation reactor: set up one alkylation reactor, the reaction temperature is 205℃, and the pressure is 4.3MPag;

[0067] Mixer supplementary absorption liquid flow: 20t / h;

[0068] The outlet pressure of the hydraulic turbine is 0.55MPag;

[0069] The deethanizer adopts 8 theoretical trays, the top pressure is 0.52MPag, and ...

Embodiment 2

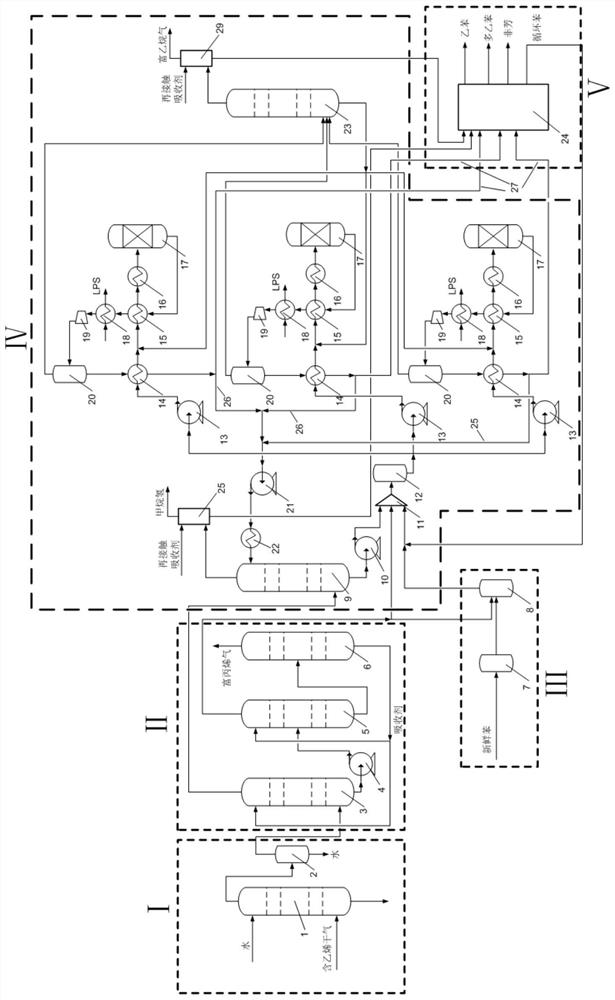

[0079] A 400,000 ton / year catalytic dry gas-liquid phase ethylbenzene production unit, using image 3 process.

[0080] in:

[0081] The theoretical plate of the absorption tower has 20 layers, the absorption pressure is 0.85MPag, and the absorption temperature is 15℃;

[0082] The ethylene desorption tower has 20 theoretical plates, the desorption tower pressure is 1.2MPag, and the top temperature is 28℃;

[0083] The ethylene absorption tower adopts a packed tower, the absorption pressure is 0.82MPag, and the absorption temperature is 40℃;

[0084] The total benzene / total ethylene molar ratio of the alkylation reaction unit feed is 2:1;

[0085] The alkylation reactor is equipped with 3 parallel feeding reactors, the reaction inlet temperature is 205°C, and the pressure is 4.3MPag;

[0086] The outlet pressure of the hydraulic turbine is 0.55MPag;

[0087] The deethanizer adopts 8 theoretical trays, the pressure at the top of the tower is 0.52MPag, and the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com