Preparation method and application of xylenol orange functionalized polyvinyl alcohol fiber

A polyvinyl alcohol fiber, orange function technology, applied in fiber processing, fiber type, analysis by chemical reaction of materials, etc., can solve the problems of polluting the environment, high cost, and non-recyclable small molecule indicators, reaching The effect of high alkali sensitivity, low cost, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

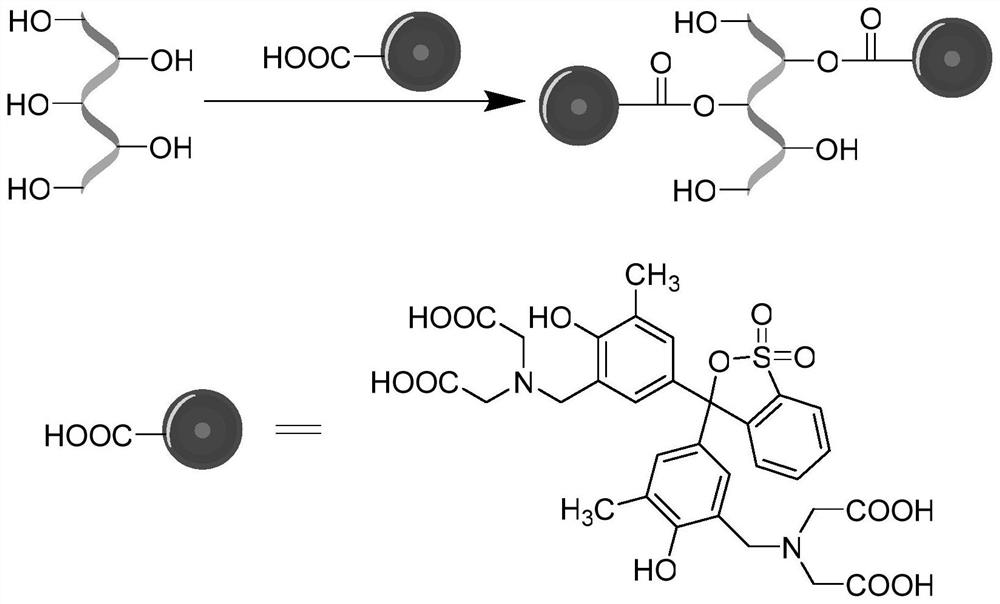

[0034] The preparation method of the xylenol orange functionalized polyvinyl alcohol fiber PVAF-XO of the present embodiment is as follows:

[0035] (1) Pretreatment of commercial polyvinyl alcohol fibers: put 5.0 g of commercial polyvinyl alcohol fibers into a 500 mL round-bottomed flask containing 300 mL of distilled water, reflux under magnetic stirring for 5 h, filter, and use 200 mL of distilled water at 65 °C. rinse. After washing, the fibers were dried in a drying oven at 60 °C for 12 h.

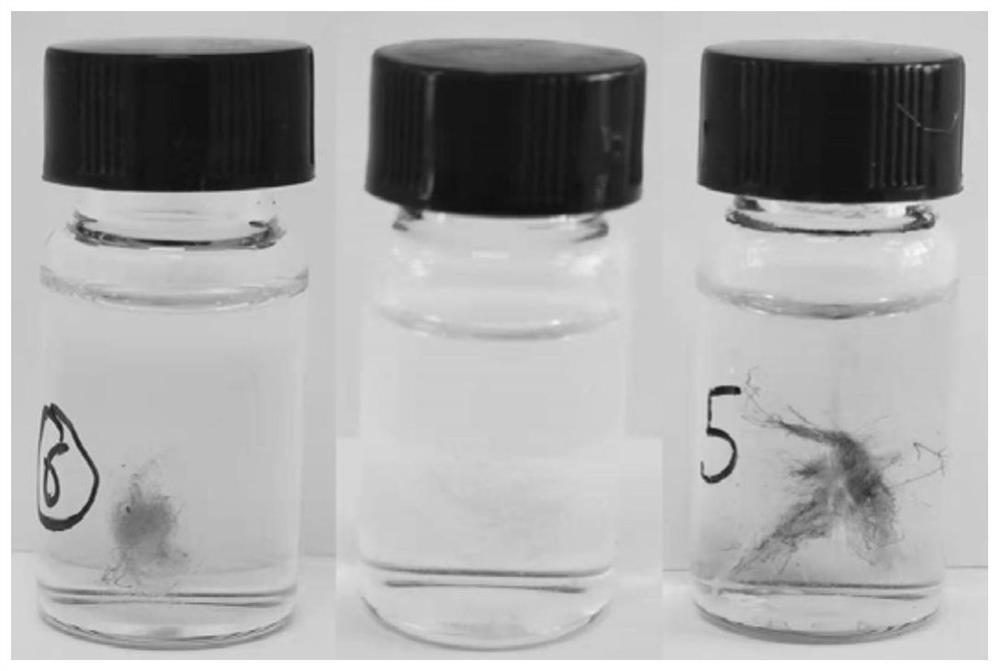

[0036] (2) Add 0.5 g of pretreated polyvinyl alcohol fibers to a 100 mL round-bottomed flask, then add 1.0 g of xylenol orange tetrasodium salt, 1 mL of concentrated phosphoric acid and 30 mL of distilled water, and reflux under magnetic stirring for 5 h. Filtration, the filtrate was collected and used for the preparation of the next batch of fibers; after the reaction, the fibers were washed with distilled water at 65 °C until the filtrate did not develop color under UV light, and f...

Embodiment 2

[0038] The preparation method of the xylenol orange functionalized polyvinyl alcohol fiber PVAF-XO of the present embodiment is as follows:

[0039] (1) Pretreatment of commercial polyvinyl alcohol fibers: put 5.0 g of commercial polyvinyl alcohol fibers into a 500 mL round-bottomed flask containing 300 mL of distilled water, reflux under magnetic stirring for 2 h, filter, and use 200 mL of distilled water at 55 °C rinse. After washing, the fibers were dried in a drying oven at 100 °C for 8 h before use.

[0040] (2) Add 0.5 g of pretreated polyvinyl alcohol fibers to a 100 mL round-bottomed flask, then add 0.5 g of xylenol orange tetrasodium salt, 0.5 mL of concentrated phosphoric acid and 30 mL of distilled water, and reflux for 4 h under magnetic stirring. Filtration, the filtrate was collected and used for the preparation of the next batch of fibers; after the reaction, the fibers were washed with distilled water at 55 °C until the filtrate did not develop color under UV ...

Embodiment 3

[0042] The preparation method of the xylenol orange functionalized polyvinyl alcohol fiber PVAF-XO of the present embodiment is as follows:

[0043](1) Pretreatment of commercial polyvinyl alcohol fibers: put 5.0 g of commercial polyvinyl alcohol fibers into a 500 mL round-bottomed flask containing 300 mL of distilled water, reflux under magnetic stirring for 10 h, filter, and use 200 mL of distilled water at 75 °C rinse. After washing, the fibers were dried in a drying oven at 80 °C for 10 h.

[0044] (2) Add 0.5 g of pretreated polyvinyl alcohol fibers to a 100 mL round-bottomed flask, then add 1.5 g of xylenol orange tetrasodium salt, 1.5 mL of concentrated phosphoric acid and 30 mL of distilled water, and reflux under magnetic stirring for 10 h. Filtration, the filtrate was collected and used for the preparation of the next batch of fibers; after the reaction, the fibers were washed with distilled water at 75 °C until the filtrate did not develop color under UV light, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com