Sampling device and sampling method for ultralow-concentration tobacco flavor substances

An aroma substance and ultra-low concentration technology, which is applied to the field of sampling devices for ultra-low concentration tobacco aroma substances, can solve the problems of accelerating the adsorption speed of tobacco natural aroma substances, unable to judge that the aromatization equipment is completely purified, and the detection sensitivity of GC-MS is reduced. , to facilitate independent filling and disassembly sampling, improve detection accuracy, and facilitate subsequent detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

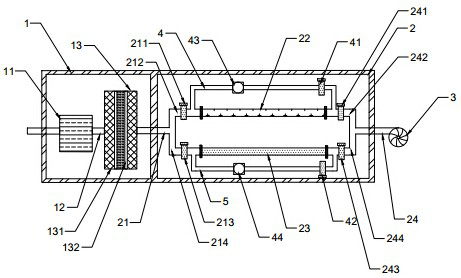

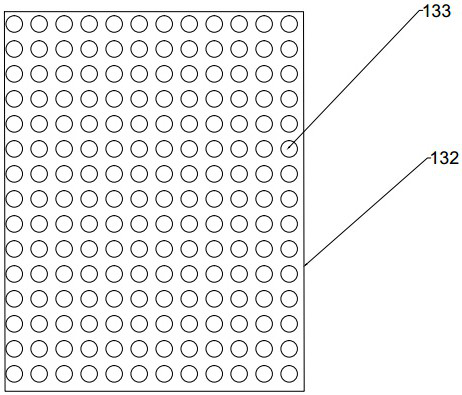

[0044] like figure 1 As shown, a sampling device for ultra-low concentration tobacco aroma substances includes a pretreatment system 1, a gas concentration system 2, and an inflator 3 that are communicated in sequence, and the pretreatment system 1 includes a heating device 11 communicated in sequence, a first communicated Pipe 12, gas impurity removal device 13, the gas concentration system 2 includes a second communication pipe 21, a first sampling pipe 22 filled with polar adsorbent, a second sampling pipe 23 filled with non-polar adsorbent, Three communication pipes 24, the first sampling pipe 22 and the second sampling pipe 23 are detachably connected in parallel between the second communication pipe 21 and the third communication pipe 24, and the second communication pipe 21 includes a A first outlet 212 of the gas flow check valve 211, a second outlet 214 of the second gas flow check valve 213, the third communication pipe 24 is provided with a first inlet 242 of the fi...

Embodiment 2

[0049] like figure 1 As shown, a sampling device for ultra-low concentration tobacco aroma substances includes a pretreatment system 1, a gas concentration system 2, and an inflator 3 that are communicated in sequence, and the pretreatment system 1 includes a heating device 11 communicated in sequence, a first communicated Pipe 12, gas impurity removal device 13, the gas concentration system 2 includes a second communication pipe 21, a first sampling pipe 22 filled with polar adsorbent, a second sampling pipe 23 filled with non-polar adsorbent, Three communication pipes 24, the first sampling pipe 22 and the second sampling pipe 23 are detachably connected in parallel between the second communication pipe 21 and the third communication pipe 24, and the second communication pipe 21 includes a A first outlet 212 of the gas flow check valve 211, a second outlet 214 of the second gas flow check valve 213, the third communication pipe 24 is provided with a first inlet 242 of the fi...

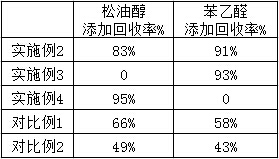

Embodiment 3

[0065] A method for sampling ultra-low concentration tobacco aroma substances using a sampling device for ultra-low concentration tobacco aroma substances as shown in Example 2, the difference is that the surface area of the tobacco straw hydrothermal charcoal described in step S1 is 1000g / m2 2 , the aperture is 2nm, the heating device 11 is heated at 50°C for 60min in step S2, in step S3, the time of normal temperature operation is 10min, the gas flow rate controlled by the first gas flow one-way control valve 211 is 0, in step S5, heating and desorption The temperature is 80 ℃, and the ultra-low concentration tobacco flavor substance to be tested is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com