High-frequency resonance transformer special for coil winding framework and plate-type ozone generator

A winding bobbin, high-frequency resonance technology, applied in the field of transformers, can solve the problems of difficult parasitic capacitance control, complex transformer parasitic parameters, transformer heating, etc., to reduce the risk of interlayer insulation breakdown, increase the effective heat dissipation area, reduce The effect of the temperature rise of the wire package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be described clearly and completely below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art fall within the protection scope of the present invention.

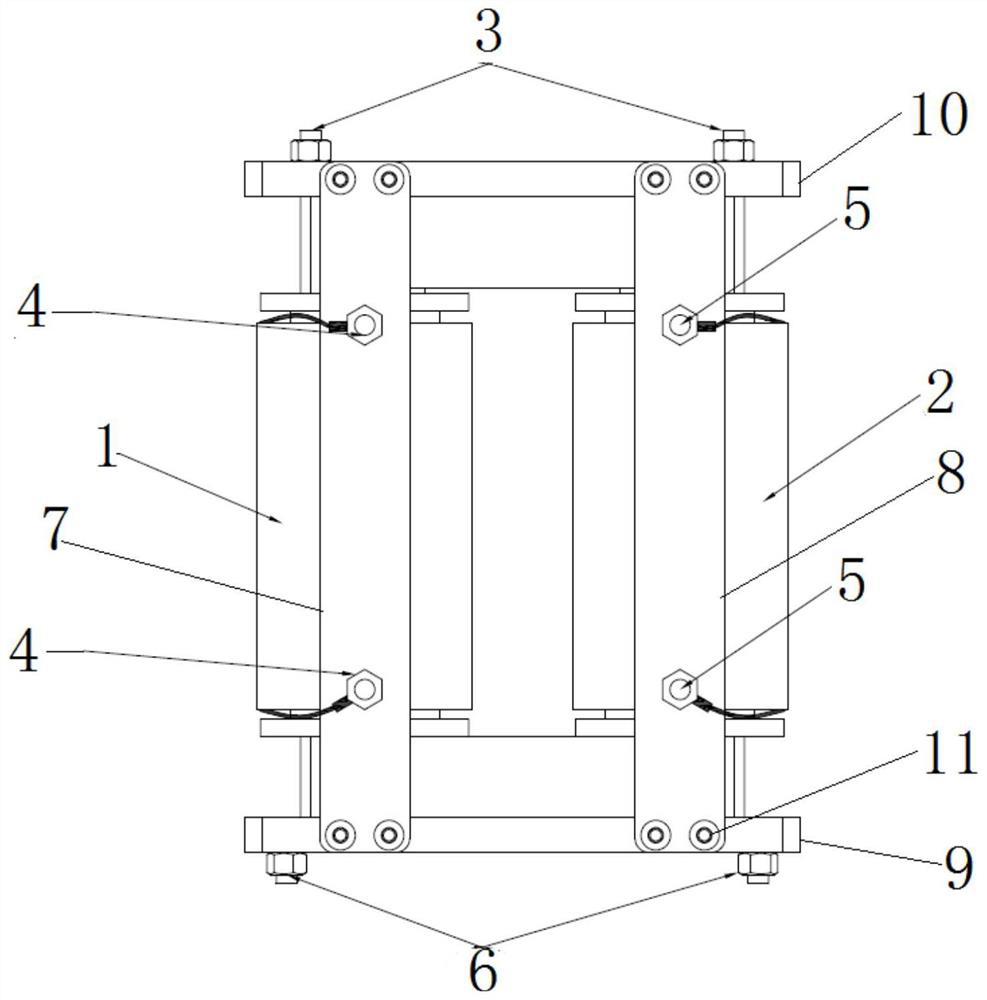

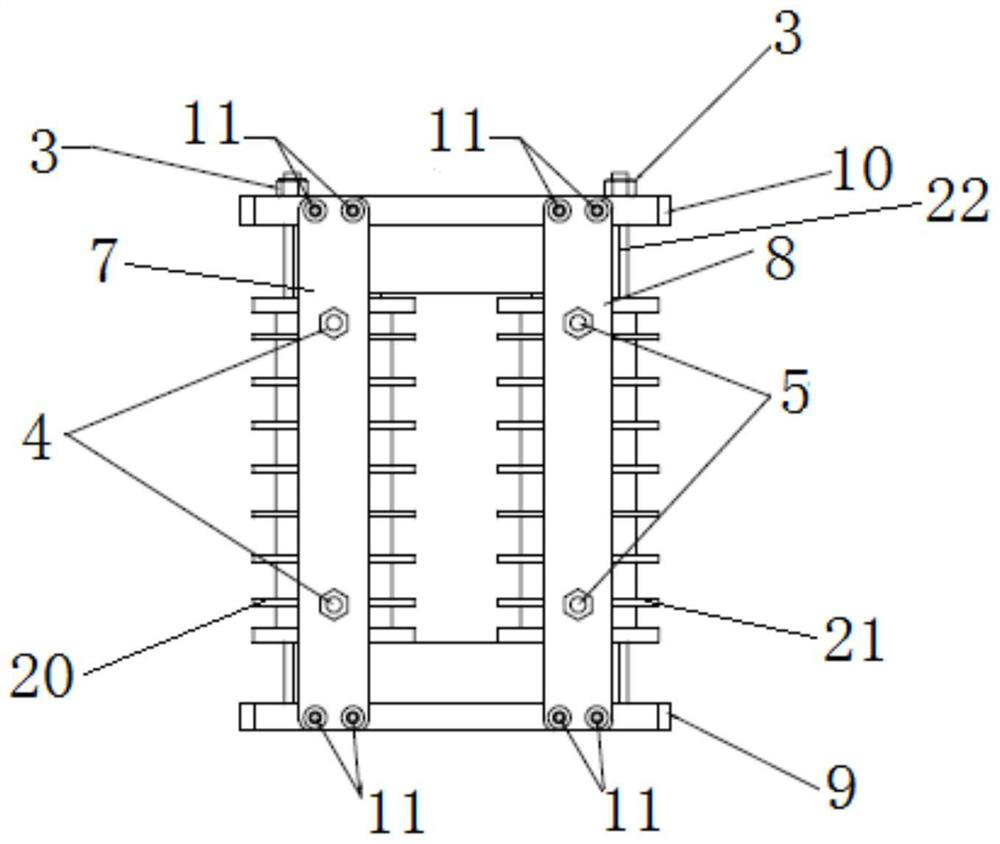

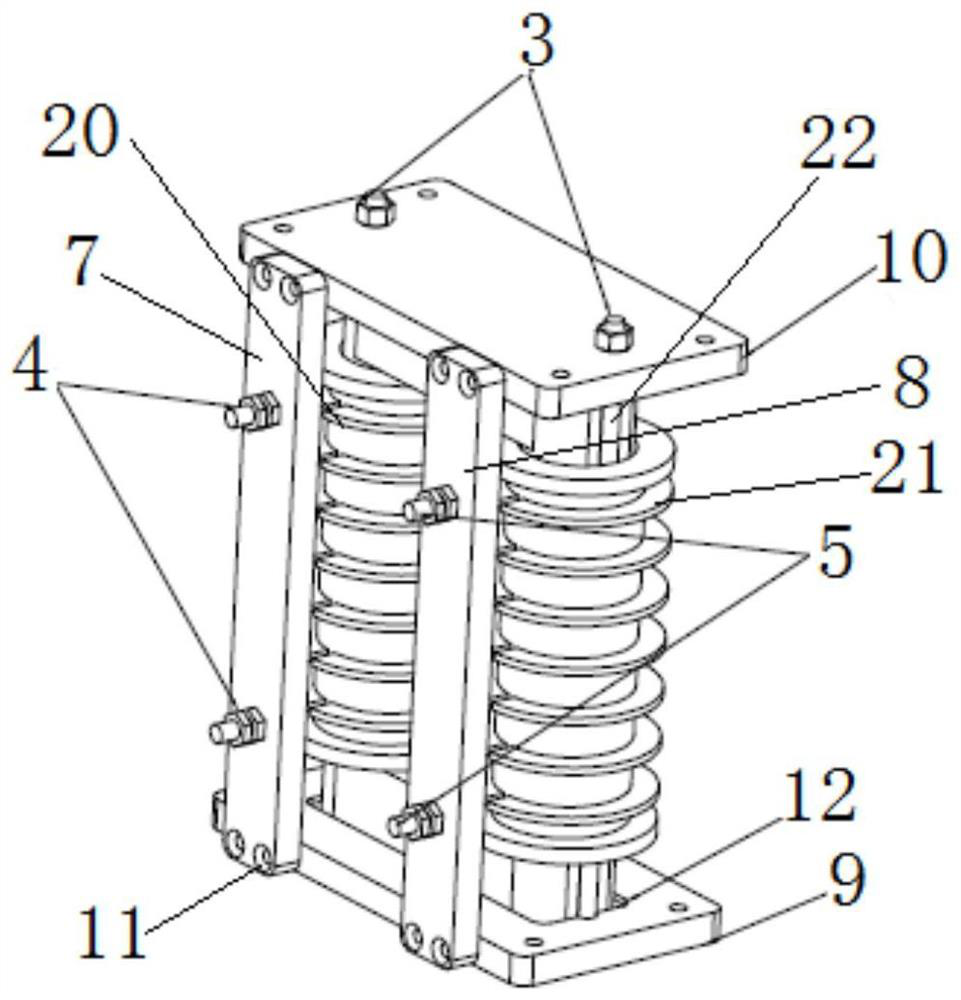

[0030] like Figure 5-6 As shown in the figure, the wire wrap wire bobbin according to the embodiment of the present invention is characterized in that it includes a skeleton body, and the upper and lower ends of the skeleton body are provided with insulating layers 14 for the wire wrap to the magnetic core. The middle part of the skeleton body is provided with a plurality of insulating interlayers 15 between the wire wraps, the lower end of the skeleton body is provided with a wire wrap wire guide groove 16, the upper end of the skeleton body is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com