Indobufen pharmaceutical composition

A technology of indobufen and its composition, which is applied in the field of medicine, can solve problems such as poor fluidity and poor granulation effect, and achieve the effects of improving dissolution rate, increasing bulk density, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Indobufen 200g

[0033] Lactose monohydrate 210.4g

[0034] Microcrystalline Cellulose 78.78g

[0035] Sodium Carboxymethyl Starch 26.3g

[0036] Magnesium Lauryl Sulfate 5.26g

[0037] Magnesium Stearate 5.26g

[0038] 1) Pre-mixing: Weigh the raw and auxiliary materials of the recipe and mix them in wet granulation for 3 minutes. The stirring speed of the wet granulator is 5r / s and the shearing speed is 20r / s;

[0039] 2) Granulation: add water to make soft materials respectively, the amount of water is 10%, 24%, 40% respectively, the stirring speed of the wet granulator is 5r / s, the shearing speed is 20r / s; grain;

[0040] 3) Drying; drying the wet granules in an oven (60°C);

[0041] 4) Granulation: dry granules are granulated through a 1.5mm screen;

[0042] 5) total mixing: add the magnesium stearate of recipe quantity and carry out total mixing;

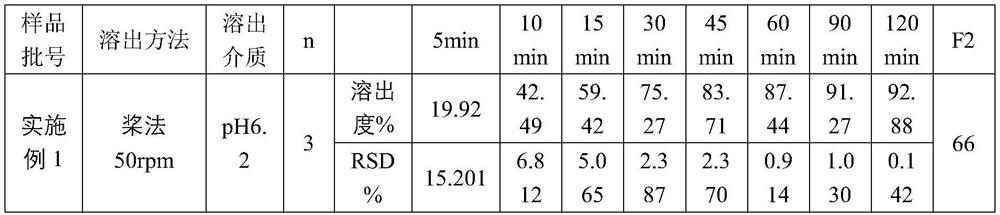

[0043] 6) Compression: Press the theoretical tablet to recompress the tablet, and the dissolution data result...

Embodiment 2

[0048] Indobufen 200g

[0049] Lactose monohydrate 210.4g

[0050] Microcrystalline Cellulose 78.78g

[0051] Sodium Carboxymethyl Starch 26.3g

[0052] Sodium Lauryl Sulfate 5.26g

[0053] Magnesium Stearate 5.26g

[0054] 1) Pre-mixing: Weigh the raw and auxiliary materials of the recipe and mix them in wet granulation for 3 minutes. The stirring speed of the wet granulator is 5r / s and the shearing speed is 20r / s;

[0055] 2) Granulation: add water to make soft material, the amount of water is 24%, the stirring speed of the wet granulator is 5r / s, the shearing speed is 20r / s; the soft material is granulated through a 1.5mm screen;

[0056] 3) Drying; drying the wet granules in an oven (60°C);

[0057] 4) Granulation: dry granules are granulated through a 1.5mm screen;

[0058] 5) total mixing: add the magnesium stearate of recipe quantity and carry out total mixing;

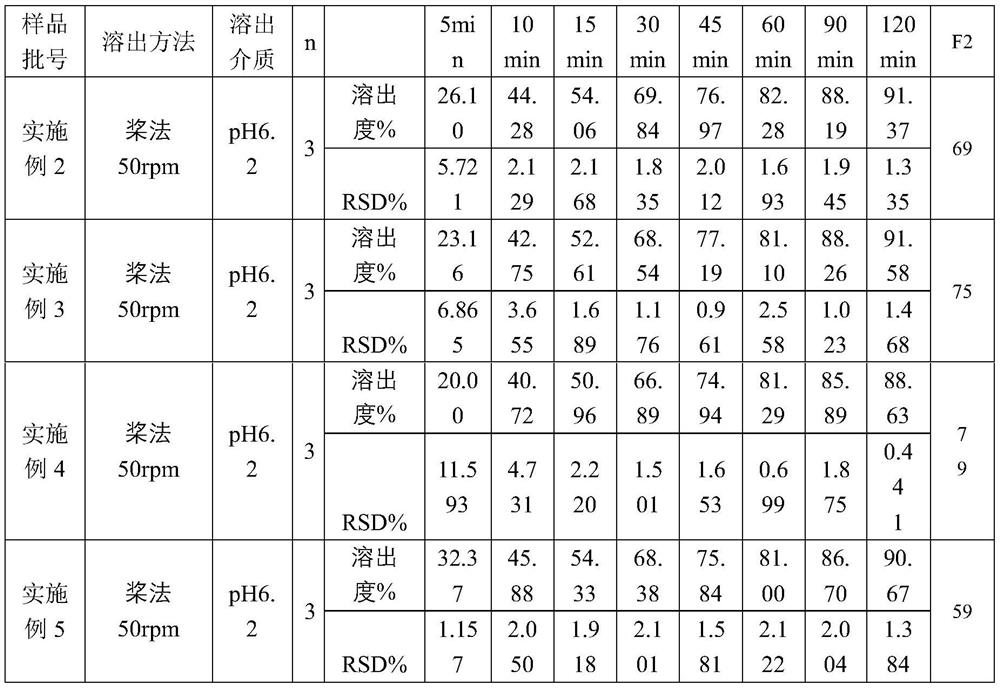

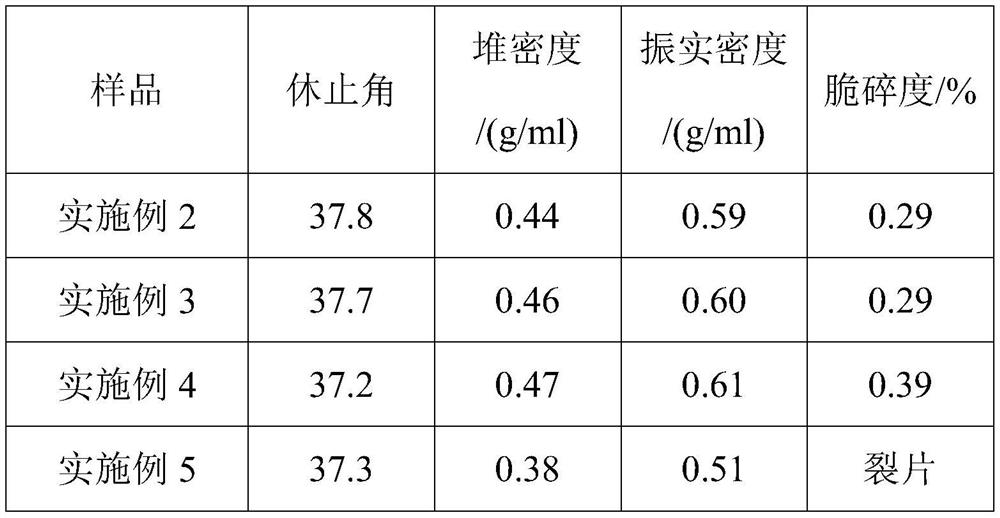

[0059] 6) Compression: Press the theoretical tablet to recompress the tablet, the dissolution data re...

Embodiment 3

[0061] Indobufen 200g

[0062] Lactose monohydrate 210.4g

[0063]Microcrystalline Cellulose 78.78g

[0064] Sodium Carboxymethyl Starch 26.3g

[0065] Sodium Lauryl Sulfate 10g

[0066] Magnesium Stearate 5.26g

[0067] 1) Pre-mixing: Weigh the raw and auxiliary materials in the formulation and mix them in wet granulation for 3 minutes. The wet granulator has a stirring speed of 5r / s and a shearing speed of 20r / s;

[0068] 2) Granulation: add water to make soft material, the amount of water is 24%, the stirring speed of the wet granulator is 5r / s, the shearing speed is 20r / s; the soft material is granulated through a 1.5mm screen;

[0069] 3) Drying; drying the wet granules in an oven (60°C);

[0070] 4) Granulation: dry granules are granulated through a 1.5mm screen;

[0071] 5) total mixing: add the magnesium stearate of recipe quantity and carry out total mixing;

[0072] 6) Tablet compression: Press the theoretical tablet to recompress the tablet, the dissolution d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com