Novel automatic manganese-zinc soft magnetic ferrite core mold

A manganese-zinc soft magnet and core mold technology, applied in inductor/transformer/magnet manufacturing, manufacturing tools, ceramic molding machines, etc., can solve the problems affecting the quality of the magnetic core, uneven force on the raw materials, and the magnetic core is not stable enough. , to achieve better quality, ensure stability, and uniform distribution of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

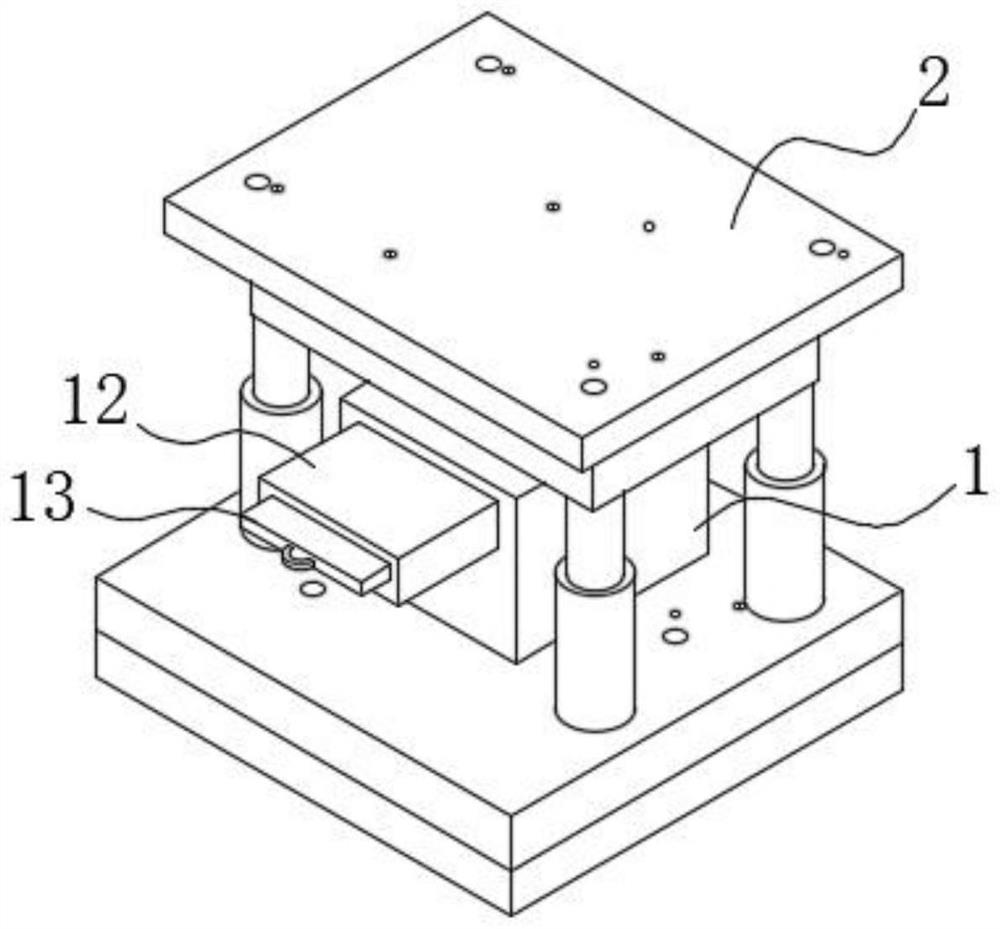

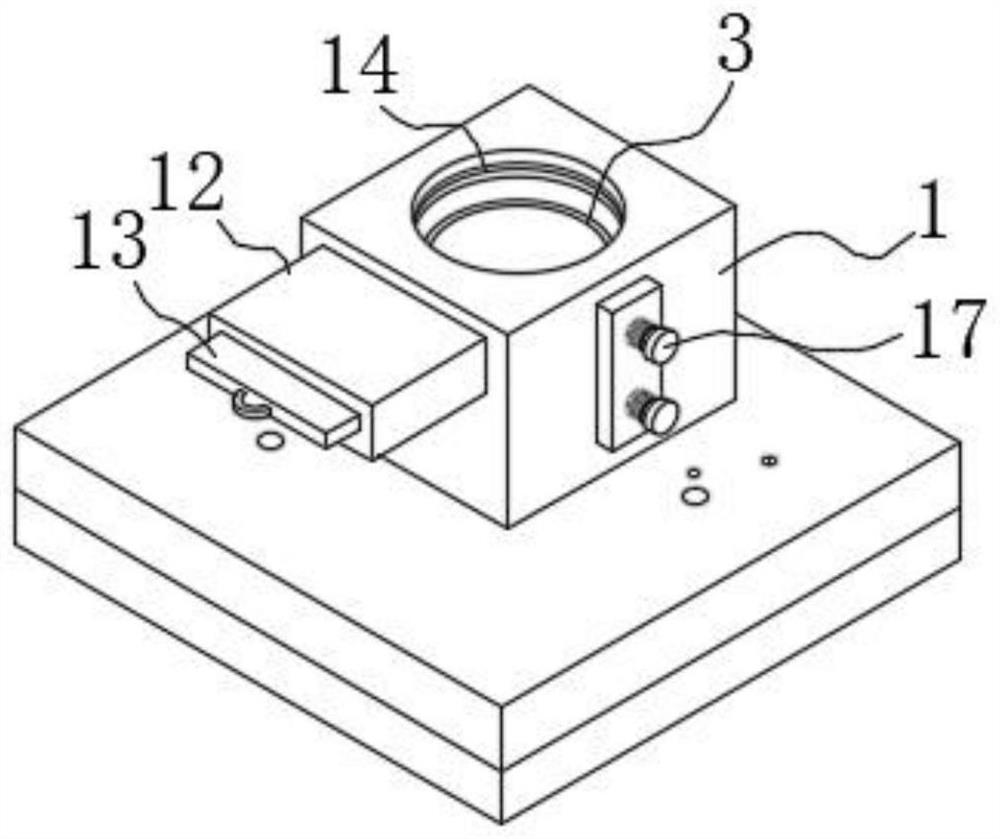

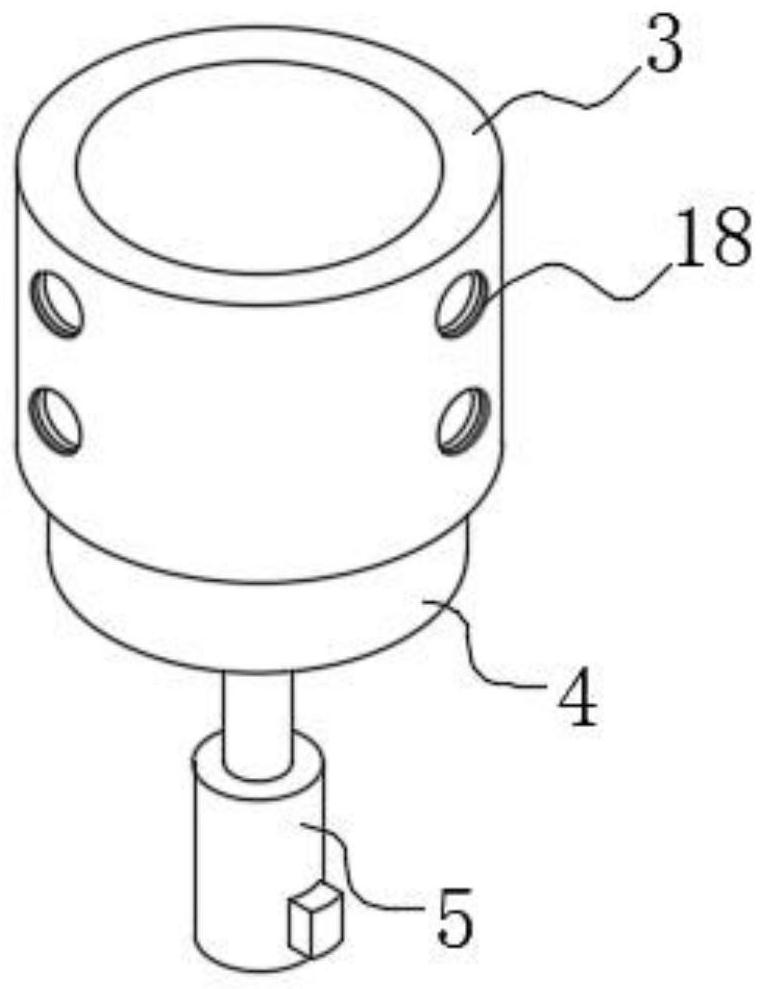

[0026] like Figure 1-Figure 7 A new type of automatic manganese-zinc soft ferrite magnetic core mold shown includes a lower die base 1, an upper die base 2 is arranged on the upper surface of the lower die base 1, and a shaping die core 3 is arranged in the die opening of the lower die base 1. , the lower surface of the inner wall of the lower die base 1 is fixedly connected to the limiting mechanism 4, and the upper surface of the limiting mechanism 4 overlaps with the lower surface of the shaping die core 3, and the limiting mechanism 4 is sleeved with a vibration mechanism 6. The vibration mechanism The bottom end of 6 is provided with a cylinder 5, and the limit mechanism 4 is provided with two inner grooves 8, the inner groove 8 is sleeved with a limit rod 7, and the bottom end of the limit rod 7 is fixedly connected with a return spring 9, and the return spring The bottom end of 9 is fixedly connected with the lower surface of the inner wall of the inner groove 8 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com