Down-conversion fluorescent powder Ba3EuAl2O7.5 with negative thermal quenching behavior and preparation method thereof

A ba3eual2o7.5, phosphor technology, applied in chemical instruments and methods, luminescent materials, inorganic chemistry, etc., can solve the problems of excitation energy loss, reduction of phosphor emission intensity, and reduction of phosphor luminous efficiency, and achieves simple process, Highly reproducible and productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

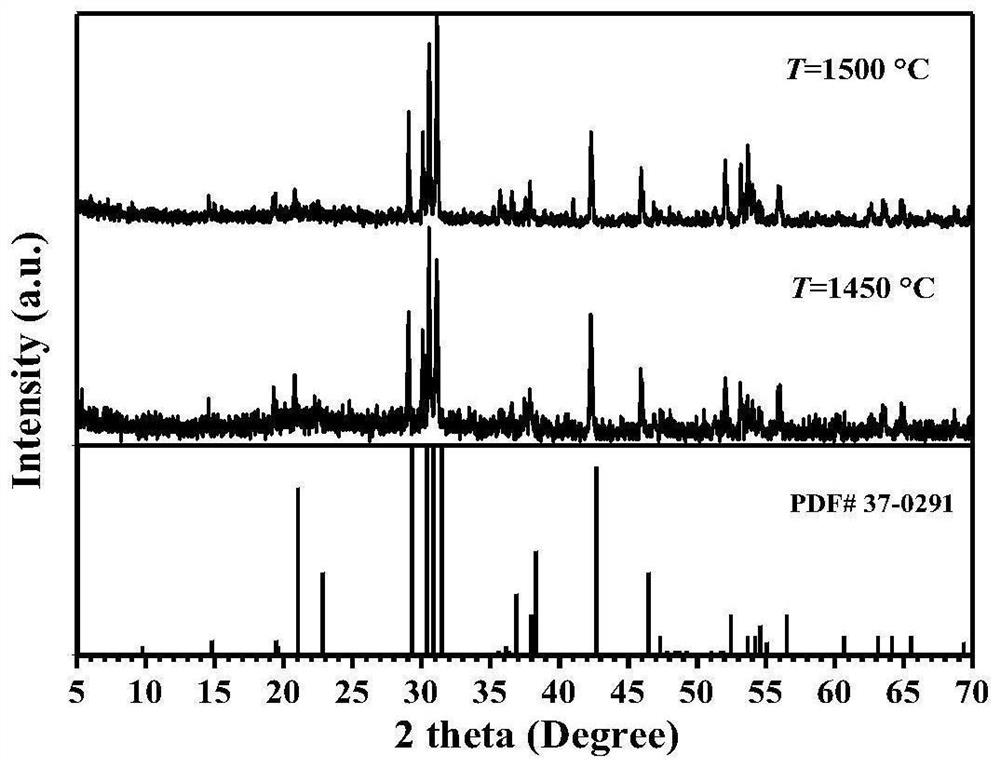

[0028] This example proposes a down-conversion phosphor Ba with negative thermal quenching behavior 3 EuAl 2 O 7.5 , belongs to the monoclinic crystal system, and the specific preparation steps are as follows:

[0029] Step 1: The raw material BaCO with a purity greater than 99.9% 3 , Eu 2 O 3 , Al(OH) 3 Weigh in a molar ratio of 6:1:4, specifically weigh 8.8803g of BaCO 3 , 2.6395g of Eu 2 O 3 and 2.3400g of Al(OH) 3 ;

[0030] Step 2: Put all the raw materials weighed in Step 1 into an agate mortar, add 30ml of anhydrous ethanol as a dispersion medium, fully grind and mix evenly to obtain a suspension;

[0031] Step 3: put the suspension obtained in step 2 into a drying box after standing for a period of time, set the drying temperature to 60°C, and dry for 8 hours to completely evaporate the absolute ethanol to obtain mixed raw materials;

[0032] Step 4: Grind the mixed raw materials obtained in step 3 again to make the mixing between the components more uniform...

Embodiment 2

[0035] This example proposes a down-conversion phosphor Ba with negative thermal quenching behavior 3 EuAl 2 O 7.5 , belongs to the monoclinic crystal system, and the specific preparation steps are as follows:

[0036] Step 1: The raw material BaCO with a purity greater than 99.9% 3 , Eu 2 O 3 , Al(OH) 3 Weigh in a molar ratio of 6:1:4, specifically weigh 8.8803g of BaCO 3 , 2.6395g of Eu 2 O 3 , 2.3400g of Al(OH) 3 ;

[0037] Step 2: Put all the raw materials weighed in Step 1 into an agate mortar, add 30ml of anhydrous ethanol as a dispersion medium, fully grind and mix evenly to obtain a suspension;

[0038] Step 3: put the suspension obtained in step 2 into a drying box after standing for a period of time, set the drying temperature to 60°C, and dry for 8 hours to completely evaporate the absolute ethanol to obtain mixed raw materials;

[0039] Step 4: Grind the mixed raw materials obtained in step 3 again to make the mixing between the components more uniform, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com