Scale inhibitor suitable for S Zorb gasoline desulfurization device as well as preparation method and application of scale inhibitor

A desulfurization device and scale inhibitor technology, applied in the treatment of hydrocarbon oil, petroleum industry, corrosion/fouling of treatment equipment, etc., can solve the problem of inability to remove odor, and achieve the effect of eliminating odor and reducing adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

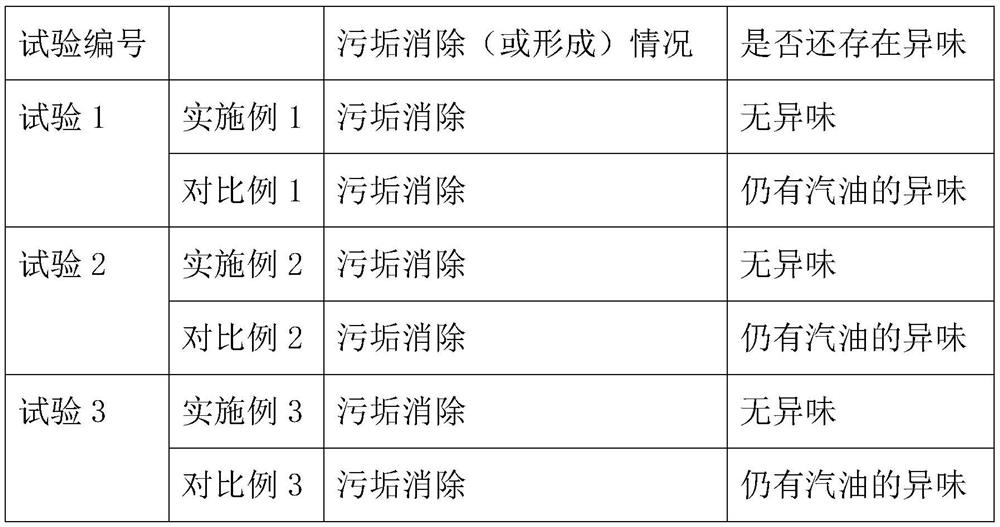

Examples

Embodiment 1

[0024] Scale inhibitor suitable for S Zorb gasoline desulfurization unit, including the following raw materials by mass: 12 parts of 2,6-di-tert-butyl-p-cresol, 7 parts of isopropyl hydroxylamine, 6 parts of polyisobutylene diimide, amino di 7 parts of sodium succinate, 4 parts of viscosity modifier, 5 parts of modified activated carbon, 7 parts of ammonium persulfate, 5 parts of oil-soluble imidazoline, and 53 parts of 120# solvent oil.

Embodiment 2

[0026] Scale inhibitor suitable for S Zorb gasoline desulfurization unit, including the following raw materials by mass: 15 parts of 2,6-di-tert-butyl-p-cresol, 9 parts of isopropyl hydroxylamine, 7.5 parts of polyisobutylene diimide, amino di 8 parts of sodium succinate, 5 parts of viscosity modifier, 6.5 parts of modified activated carbon, 8.5 parts of ammonium persulfate, 6 parts of oil-soluble imidazoline, 65 parts of 120# solvent oil.

Embodiment 3

[0028] Scale inhibitor suitable for S Zorb gasoline desulfurization unit, including the following raw materials by mass: 17 parts of 2,6-di-tert-butyl-p-cresol, 11 parts of isopropyl hydroxylamine, 9 parts of polyisobutylene diimide, amino di 9 parts of sodium succinate, 6 parts of viscosity modifier, 8 parts of modified activated carbon, 10 parts of ammonium persulfate, 7 parts of oil-soluble imidazoline, 74 parts of 120# solvent oil.

[0029] In the above examples 1-3, 2,6-di-tert-butyl-p-cresol is used as antioxidant, and 2,6-di-tert-butylphenol, 2-tert-butyl-4,6-dimethylphenol can also be used Any one of phenol, 2,6-di-tert-butyl-4-ethylphenol and 2,6-di-tert-butyl-4-n-butylphenol is used instead; for the same reason, isopropyl hydroxylamine is used as hydroxylamine It can be used as a polymerization inhibitor, and can also be used in any one or two of hydroxylamine, ethylhydroxylamine, N,N'-diethylhydroxylamine, N,N'-diisopropylhydroxylamine and N,N'-dibutylhydroxylamine....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com